ESEGAS is proud to share the successful installation of its Ultrasonic Gas Flow Meter (LEUF Series) across battery manufacturing plants worldwide. Based on the on-site conditions, the ultrasonic gas flow meter was installed on a horizontal flue duct with a diameter of 1.5 meters. The probe was positioned at a 45° angle, ensuring optimal alignment for ultrasonic signal transmission.

Before installing the ultrasonic gas flow meter, engineers should carefully verify several key conditions to ensure accurate and stable measurement performance:

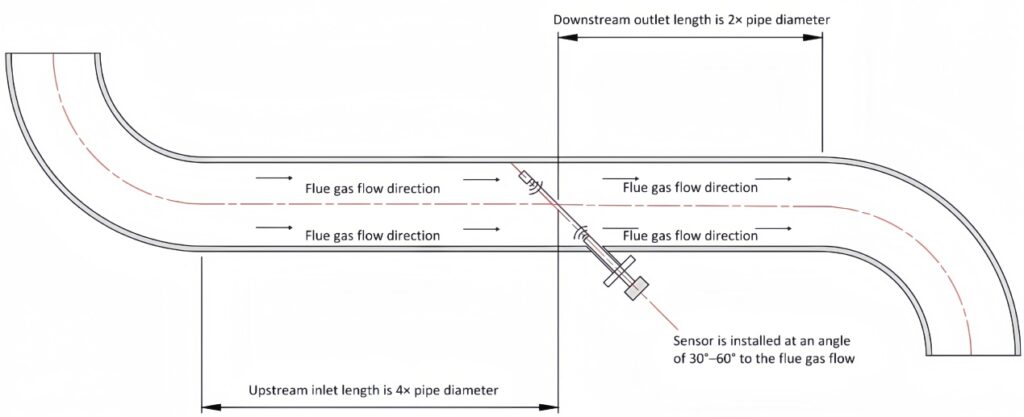

- Straight Pipe Lengths: Maintain at least 4× the pipe diameter upstream and 2× downstream of the sensor to achieve a fully developed, laminar flow profile.

- Mounting Angle: Keep the installation angle between 30° and 60°relative to the pipe axis. This range provides optimal ultrasonic signal transmission and minimizes reflection losses.

- Probe Alignment: Ensure single probe is properly aligned on the duct to maintain a clear and consistent sound path.

- Avoid Flow Disturbances: Do not install near bends, valves, or reducers, as turbulence can affect measurement accuracy.

- Temperature and Vibration: Confirm that the installation point is free from excessive vibration and extreme temperature fluctuations that could impact signal stability.

By following these installation guidelines, the ESEGAS Ultrasonic Gas Flow Meter can deliver precise, repeatable, and reliable gas flow data under real-world industrial conditions.

Explore more details about our ultrasonic gas flow meter, watch our YouTube video. Learn more about ESEGAS ultrasonic gas flow meter and process gas analysis solutions at: www.esegas.com | Contact us: [email protected]

#IndustrialAutomation #ProcessControl #FlowMeasurement #CleanEnergy #IndustrialEfficiency