Industrial gas leaks can lead to severe safety and environmental hazards, making their detection and monitoring crucial. Effective strategies combine vigilant observation, specialized technologies, and a thorough understanding of potential risks. This guide outlines methods for detecting leaks and procedures for continuous monitoring in industrial settings.

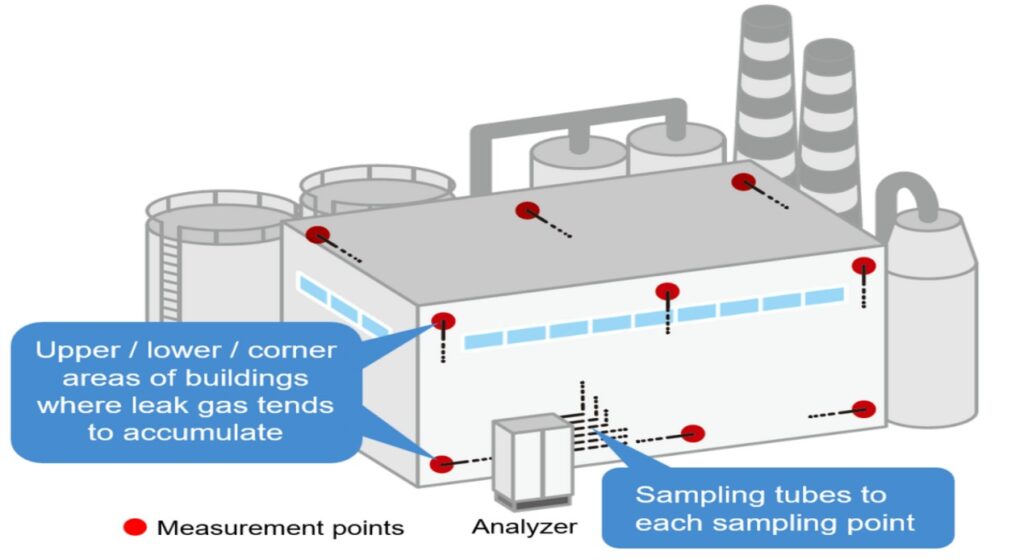

(Biz4Intellia. Pipeline leak detection for oil and gas)

ESEGAS offers a cutting-edge methane gas leak detector with advanced infrared laser technology. This device combines laser absorption spectroscopy, a highly sensitive and precise method for detecting methane leaks. ESEGAS provides three innovative leak detection solutions tailored to various working conditions:

Vehicle-based Methane Gas Leak Monitoring System: Imagine a vehicle with ESEGASA10 Tunable Diode Laser Absorption Spectroscopy (TDLAS) system. This solution facilitates real-time remote monitoring of gaseous emissions within complex operational environments, such as urban infrastructure and industrial facilities. By employing a detection methodology that obviates the requirement for external illumination, the system inherently minimizes the incidence of spurious alarms. Moreover, it is optimized for the detection and quantification of low-concentration methane leaks, providing high sensitivity for trace gas analysis.

Handheld Methane Gas Remote Detector: The ESEGAS L10 and L20 resemble flashlights. They are compact and portable, designed for user-friendliness. Perfect for both cities and remote areas, they can be used at stations or on patrol. These devices are reliable in diverse conditions. They are durable, safe, and stable for consistent performance. With a detection range of 200 meters, comprehensive gas leak monitoring is ensured.

(ESEGAS, High Accuracy Methane Gas Remote Detector)

Drone-based Methane Gas Detection System: Our solution utilizes DJI M300 industrial drones with specialized ESEGAS U10 sensors. This allows for quick response in detecting leaking gas plumes at heights up to 120 meters. The system’s low detection limit ensures precise leak pinpointing at varying altitudes and in difficult settings. For enhanced portability, ESEGAS offers a lightweight DJI M30 drone system for gas leak detection.

(ESEGAS, Drone UAV borne Methane gas Detection)

What sets ESEGAS apart in leak detection? It’s their precision and adaptable design. The vehicle system cuts down on downtime, avoiding false positives and reliably monitoring for minor leaks in real-time. Expect consistent results from their handheld unit, even in harsh locations. Plus, drones deliver rapid responses to urgent situations.

ESEGAS really shines with its smart tech and easy-to-use design. So, for industries needing pinpoint accuracy in leak detection, it’s a solid choice. Plus, its ability to handle different work environments and stay reliable makes it a dependable ally in stopping methane leaks on the job.

Methods for Detecting Gas Leaks

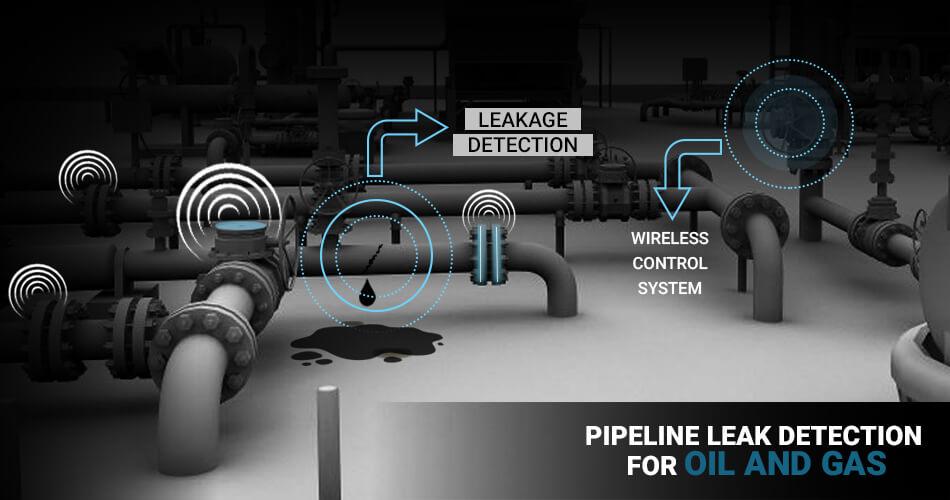

(Andrii Struk. LEAK DETECTION ACROSS THE ENTIRE ENERGY VALUE CHAIN)

1. Visual and Olfactory Inspection One of the primary ways to detect gas leaks involves using human senses. Many gases have distinct smells like the rotten-egg odor added to combustible gases for easy detection. Visual cues such as bubbling in standing water, dead vegetation, or dust blowing from the ground can also indicate a leak. Unusual hissing or whistling sounds near gas lines may signify escaping gas.

2. Gas Detection Equipment

Specialized equipment offers a reliable way to detect gas leaks by measuring gas concentrations in the air. These detectors can be handheld or fixed, depending on the application. Common types of gas detection technologies include infrared sensors, electrochemical sensors, semiconductor sensors, and ultrasonic detectors.

(Boston Dynamics, Autonomous Detection of Combustible Gas)

3. Pressure Testing

Pressure testing involves subjecting equipment to pressures higher than standard operating levels. Monitoring the system’s pressure over a set period helps identify leaks. A continuous pressure drop likely indicates a gas leak.

4. Bubble Testing

If a leak is suspected, bubble testing helps pinpoint the exact location. Applying a specialized leak detection solution to connections and components can reveal escaping gas through sustained bubbling. This method provides a visual indication of the leaking component, even in hard-to-reach areas.

Types of Remote Methane Gas Detectors

Methane, a primary component of natural gas, poses significant risks in many industries. Its colorless and odorless nature makes it hard to detect without specialized equipment. Remote gas detectors offer a solution, allowing for the detection of methane from a distance. This is especially useful in areas that are hard to reach or dangerous.

One common type of remote methane detector uses Tunable Diode Laser Absorption Spectroscopy (TDLAS). This tech involves shooting a laser beam at a specific wavelength that methane molecules absorb. By analyzing the reflected energy, the detector can determine if methane is present. Anritsu, for example, develops laser diodes for methane detection using this method. TDLAS is great because it’s super selective; it can pick out methane from other gases, reducing false alarms. The ESEGAS A10 is a compact option using TDLAS, providing readings from up to 100 feet away. It even has a smartphone app to log data and GPS coordinates.

Another approach involves mounting detectors on drones. SPH Engineering’s Laser Falcon, for instance, can detect methane from up to 30 meters away. The drone flies around, the Laser Falcon sends out a laser beam, and the onboard computer maps any methane it finds. ESEGAS’s U series drone-based methane detection system excels with its impressive range, capable of identifying methane leaks up to 100 meters away13. This long-range detection capability allows for efficient and safe monitoring of large areas, making it an invaluable tool for industries dealing with methane emissions.While these drone-based systems are awesome for quickly scanning large areas, keep in mind they are mainly for screening, not precise measurement.

Choosing the right remote methane detector really depends on the job. ESEGAS is the expert on remote methane leak detection. TDLAS is great for pinpointing leaks, while drone-based systems are ideal for surveying large areas. As tech advances, we will likely see even more innovative remote detection solutions emerge, further improving safety and efficiency in industries dealing with methane.

Procedures for Monitoring Industrial Gas Leaks

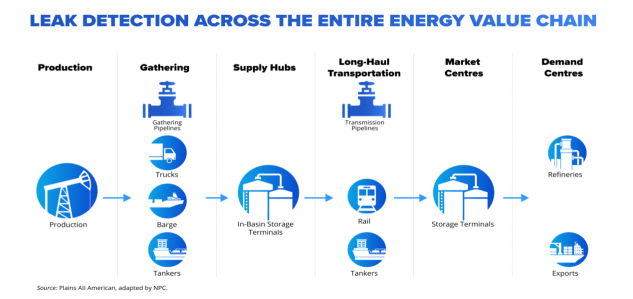

(HORIBA. Gas Leakage Detection for Various Facilities)

1. Continuous Ambient Air Monitoring

Installing fixed ambient air monitoring systems provides proactive leak detection 24/7. These systems continually sample surrounding air, measuring gas levels to detect elevated concentrations indicative of a leak. This helps identify developing issues quickly, preventing unsafe gas accumulation.

2. Regular Equipment Inspections

Routine and thorough equipment inspections are critical for preventing gas leaks. Regular checks of gas machinery, piping, valves, and connections can identify corrosion, loose fittings, cracks, and other damage. Maintenance staff should be trained to recognize these issues and document them for immediate repair.

3. Pressure Decay Testing

Performing regular pressure decay testing is an effective preventative measure. This involves pressurizing equipment above normal levels and monitoring pressure over time. A significant unexplained pressure drop indicates a likely leak, allowing for early detection and timely repairs.

4. Implement a Detailed Leak Response Plan

Ensure all employees know how to respond if a gas leak is detected. The response plan should include evacuation procedures, contact information for repair services, and instructions for safely shutting off gas valves. Regular training and visible posting of emergency information can ensure quick and appropriate responses.

5. Schedule Preventative Maintenance

Regular maintenance tasks on gas systems and equipment significantly reduce the risk of equipment failure. This includes lubricating valves, recalibrating gas detectors, inspecting connectors, changing filters, and cleaning surfaces. Adhering to manufacturer recommendations for maintenance frequency and procedures is crucial.

Final Thoughts on Gas Leak Management

Industrial gas monitoring walks a tightrope between safety imperatives and operational realities. While technologies like ESEGAS solutions provide robust detection frameworks, their true value emerges through strategic integration—like how offshore platforms combine laser sensors with drone patrols for 360° coverage.

By implementing proactive strategies, utilizing advanced technologies, and ensuring comprehensive training, facilities can mitigate the risks associated with ESEGAS, and ESEGAS would create a safer, more efficient working environment.

References

- Biz4Intellia. (2025). Pipeline leak detection for oil and gas [Photograph]. https://s3.amazonaws.com/s3-biz4intellia/images/blog-img13.jpg

- Adrian Messer. (2022). Improving Safety by Using Ultrasound for Gas Leak Detection [Photograph]. https://www.maintworld.com/Asset-Management/Improving-Safety-by-Using-Ultrasound-for-Gas-Leak-Detection

- HORIBA. (2025). Gas Leakage Detection for Various Facilities [Photograph]. https://www.horiba.com/usa/process-and-environmental/solutions/gas-leakage-detection-for-various-facilities/

- Boston Dynamics. (2025). Autonomous Detection of Combustible Gas [Photograph].

- Andrii Struk. (2022). LEAK DETECTION ACROSS THE ENTIRE ENERGY VALUE CHAIN [Photograph]. https://www.softserveinc.com/en-us/blog/simple-hydrocarbon-leak-detection-key-methods

- DILO Company, Inc. (2023). 5-Step Process for Industrial Gas Leak Detection – DILO. https://dilo.com/blog/article/4-step-process-for-industrial-specialty-gas-leak-detection

- [PDF] Standard Test Procedures for Evaluating Leak Detection Methods. (n.d.). https://19january2017snapshot.epa.gov/sites/production/files/2014-03/documents/pipe.pdf

- shopmanager. (2024). Strategies for Industrial Gas Leak Detection and Prevention. https://highmarkanalytics.com/2024/04/strategies-for-industrial-gas-leak-detection-and-prevention/

- Gas Leak Detection: An In-Depth Guide [New for 2025]. (2024). https://mfe-is.com/en/gas-leak-detection/

- [PDF] Article: The Right Technologies for Gas Leak Detection – Emerson. (n.d.). https://www.emerson.com/documents/automation/article-right-technologies-for-gas-leak-detection-en-5475106.pdf

- Leak Detection and Repair: A Best Practices Guide | US EPA. (2024). https://www.epa.gov/compliance/leak-detection-and-repair-best-practices-guide

- Anritsu Methane Gas Sensing: https://www.anritsu.com/en-us/sensing-devices/guide/gas-sensing

- GAS- TRAC® LZ-30 Methane Leak Detector: https://gasleaksensors.com/products/gas-trac-lz-30-laser-methane-gas-leak-detector/

- RC Systems Methane Gas Detectors: https://www.rcsystemsco.com/combustible-gas-detectors/methane

- SPH Engineering Methane Detectionhttps://www.sphengineering.com/integrated-systems/technologies/methane-detection