In industries where precision is non-negotiable—such as semiconductor manufacturing, chemical production, or environmental monitoring—trace gas detection plays a pivotal role. The inability to detect gases at extremely low concentrations can lead to product defects, safety hazards, or regulatory violations. Many existing gas analysis technologies fall short in sensitivity, speed, or reliability. ESEGAS has developed a cutting-edge Trace Gas Analyzer to address these challenges with unparalleled precision and flexibility. Utilizing a combination of NDIR (Non-Dispersive Infrared), TCD (Thermal Conductivity), and ECD (Electrochemical Detection) technologies, the IR-GAS-600 offers ultra-low detection limits, rapid response time, and high stability for long-term monitoring in complex gas environments.

Despite knowing that trace gas detection is critical, many professionals still rely on outdated or generic analyzers. However, not all analyzers are created equal. If you’re serious about reliability and accuracy, it’s time to explore why ESEGAS stands out.

What Is the Core Detection Technology Behind the IR-GAS-600?

Many trace gas analyzers promise sensitivity, but few explain how they achieve it—ESEGAS is different.

The IR-GAS-600 combines multiple sensor technologies into a modular system. It uses:

- NDIR to detect infrared-absorbing gases like CO₂ and CH₄.

- TCD to measure gases based on thermal conductivity, ideal for detecting inert gases.

- ECD for electrochemical analysis, ensuring fast response to reactive gases like O₃ or NO₂.

This hybrid sensor architecture enables the device to detect gas concentrations as low as ppm or ppb levels, depending on the sensor module. Additionally, real-time signal processing and calibration ensure data integrity even in fluctuating conditions.

How Does the IR-GAS-600 Excel in Trace Gas Detection Performance?

Accuracy means nothing without speed, stability, and reliability in real-world environments.

ESEGAS’s Trace Gas Analyzer is engineered with:

- Detection range: as low as 0–10 ppm, up to 0–100% depending on gas type.

- Response time (T90): typically under 5 seconds.

- Repeatability and accuracy: ≤±1.0% of full scale.

- Data communication: 4–20 mA output, RS485, Modbus compatibility.

These specs are not just numbers—they translate to actionable intelligence in high-stakes environments such as trace gas monitoring in cleanrooms or process plants. Operators can immediately detect shifts, prevent leaks, and maintain compliance without manual recalibration.

What Industrial Applications Can Benefit Most from Trace Gas Analyzers?

Knowing a technology exists is not enough—understanding where and how to apply it defines its true value.

While many instruments are built for generalized use, the Trace Gas Analyzer by ESEGAS is engineered for industries where precision gas monitoring is mission-critical. In these settings, even slight deviations in gas composition can result in safety hazards, product defects, or regulatory non-compliance. Therefore, selecting a reliable, fast-response trace gas analyzer becomes more than a technical decision—it’s a strategic one.

Here are some of the most impactful application areas:

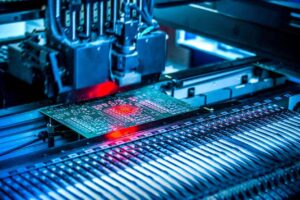

1. Semiconductor Manufacturing

- Why It Matters: Semiconductor fabrication demands an ultra-clean environment. Minute impurities or gas leaks can destroy wafers worth thousands of dollars.

- How the Analyzer Helps: ESEGAS’s trace gas analyzer can detect extremely low concentrations of gases such as NH₃, HF, or HCl, ensuring contamination-free production lines and maintaining Class 1 cleanroom standards.

2. Industrial Gas Leak Detection

- Why It Matters: Gas leaks not only threaten worker safety but can also cause operational downtime or catastrophic failures.

- How the Analyzer Helps: With real-time monitoring and fast response (T90 < 5s), this device allows for early detection of flammable, toxic, or inert gas leaks—critical in chemical plants, storage facilities, or gas distribution networks.

3. Environmental Monitoring & Compliance

- Why It Matters: Regulatory frameworks like the EPA or EU Industrial Emissions Directive demand continuous emissions monitoring with verifiable accuracy.

- How the Analyzer Helps: ESEGAS analyzers are ideal for stack gas analysis, VOC tracking, or greenhouse gas emissions from combustion systems, enabling precise data for reporting and compliance.

4. Hydrogen Production & Electrolysis Plants

- Why It Matters: Purity of hydrogen gas and the detection of oxygen or moisture contamination are key to process efficiency and equipment longevity.

- How the Analyzer Helps: ESEGAS provides high-selectivity sensors that distinguish between hydrogen and trace impurities, ensuring production purity and reducing equipment wear.

5. Laboratory & Research Facilities

- Why It Matters: Research experiments involving gas reactions require stable and traceable atmospheric control.

- How the Analyzer Helps: With flexible sensor modules and customizable calibration, ESEGAS’s solution supports accurate and repeatable experimentation, from gas chromatography to material science.

6. Waste Incineration & Biogas Plants

- Why It Matters: In these high-particulate, corrosive environments, durable and accurate gas analysis is crucial for both performance and safety.

- How the Analyzer Helps: With its rugged IP65 design and corrosion-resistant housing, the trace gas analyzer reliably measures critical gases such as SO₂, H₂S, and CH₄ under extreme conditions.

| Application Area | Why It Matters | How ESEGAS Trace Gas Analyzer Helps |

| Semiconductor Manufacturing | Cleanroom purity is vital; trace contaminants ruin high-value wafers | Detects low-level NH₃, HF, HCl; ensures Class 1 cleanroom compliance |

| Industrial Gas Leak Detection | Leaks threaten safety and continuity | Real-time, fast-response detection of toxic, flammable, or inert gases |

| Environmental Compliance | Regulatory bodies require accurate emissions data | Supports stack gas analysis, VOC tracking, and greenhouse gas monitoring |

| Hydrogen Production | Gas purity affects fuel cell efficiency and safety | Identifies O₂, H₂O impurities in hydrogen; ensures high-purity output |

| Research & Laboratories | Experiments require stable, precise atmospheric conditions | Modular sensors allow flexible, accurate, and repeatable trace gas monitoring |

| Waste Incineration / Biogas | Harsh conditions need robust, long-term monitoring | IP65-rated housing; measures SO₂, H₂S, CH₄ accurately even in corrosive or dusty environments |

What Makes ESEGAS a Trusted Manufacturer of Trace Gas Analyzers?

You don’t just buy a device—you invest in expertise, support, and long-term performance.

ESEGAS integrates German engineering and sensor technology with a user-centric design philosophy. Key advantages include:

- Modular sensor replacement without factory returns.

- Built-in zero and span calibration.

- Durable housing (IP65-rated) suitable for harsh environments.

- Customizable ranges and alarm settings.

The company’s deep domain expertise and commitment to R&D make it a reliable partner for organizations that depend on accurate trace gas analyzer performance, day in and day out.

Conclusion: Why ESEGAS Trace Gas Analyzer Is the Smart Choice

When accuracy, speed, and flexibility matter, the ESEGAS Trace Gas Analyzer delivers. With advanced multi-sensor technology, real-world-tested durability, and broad industry applications, it offers unmatched value for professionals who can’t afford to guess. Whether you’re monitoring trace gases for safety, compliance, or quality, ESEGAS ensures you always have the data you need—when you need it most.