Emission Regulations Are Tightening—Are You Measuring Accurately?

In today’s increasingly regulated industrial and environmental landscapes, businesses across the globe face one critical challenge: ensuring emissions compliance while maintaining operational efficiency. Traditional methods of monitoring exhaust gases are often inefficient, lack precision, and fall short of regulatory demands. This creates significant financial and environmental risks.

But what if there was a smarter, more reliable way to analyze and manage emissions?

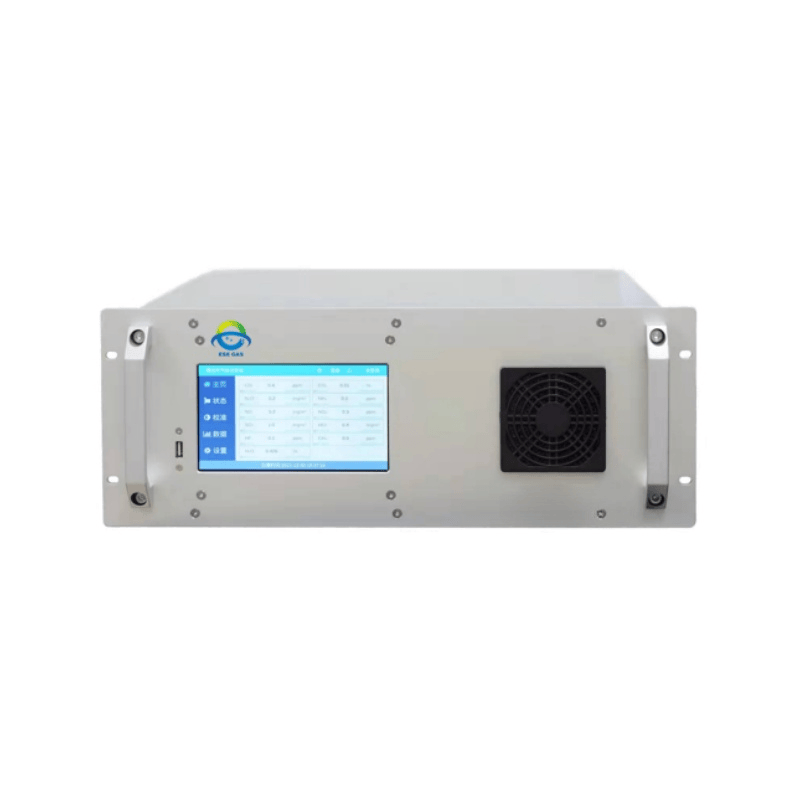

Enter the exhaust gas analyzer—a powerful tool that’s transforming how industries measure and control emissions. In this article, we’ll explore what an exhaust gas analyzer is, how it works, and why ESEGAS is at the forefront of this essential technology.

An Exhaust Gas Analyzer is an Instrument That Measures the Concentration of Gases Emitted from Combustion Processes Across Industries.

It’s designed to quantify gases like CO₂, CO, NOₓ, SO₂, O₂, CH₄, and hydrocarbons, among others. These analyzers are indispensable in settings such as power plants, manufacturing facilities, vehicles, and environmental monitoring stations.

ESEGAS’s analyzers provide advanced measurement capabilities using technologies such as FTIR, TDLAS, NDIR, and UV-DOAS, ensuring industry-leading precision, stability, and multi-gas coverage.

Even if you’re already familiar with the basics of exhaust gas analysis, understanding how technologies like TDLAS and UV-DOAS are changing the landscape—and how ESEGAS integrates them—can give you a competitive edge. From ensuring CEMS compliance to optimizing combustion efficiency, this knowledge is critical for engineers, compliance officers, and plant operators.

What Is an Exhaust Gas Analyzer?

Regulatory Pressure Is Rising—Can Your Systems Keep Up?

As emission limits tighten worldwide, especially in sectors like energy, chemicals, and manufacturing, having accurate gas composition data is no longer optional.

An exhaust gas analyzer is a device that detects and quantifies gases in the exhaust stream of combustion processes. These gases may include:

- Carbon dioxide (CO₂)

- Carbon monoxide (CO)

- Nitrogen oxides (NO, NO₂, NOₓ)

- Sulfur dioxide (SO₂)

- Methane (CH₄), hydrocarbons (HCs), oxygen (O₂)

- Ammonia (NH₃), hydrogen chloride (HCl), and more

Most modern analyzers, such as those from ESEGAS, employ advanced spectroscopic techniquesincluding:

- NDIR (Non-Dispersive Infrared): Ideal for detecting CO, CO₂, and hydrocarbons

- UV-DOAS (Ultraviolet Differential Optical Absorption Spectroscopy): High-accuracy measurement for SO₂, NO, NO₂, NH₃

- TDLAS (Tunable Diode Laser Absorption Spectroscopy): Excellent for ppb detection of NH₃, HF, HCl, CH₄, and other trace gases

- FTIR (Fourier Transform Infrared): Allows multi-gas portable analysis with simultaneous detection of over 10 gases

How Does ESEGAS Elevate Gas Analysis Technology?

One Analyzer. Multiple Gases. Zero Compromise.

ESEGAS takes gas analysis a step further by offering highly integrated, application-specific analyzersbuilt for performance, portability, and compliance. Below are ESEGAS’s flagship technologies and products:

| Analyzer Type | Key Features | Typical Applications |

| Portable FTIR Gas Analyzer | Multi-gas detection (CO, NOₓ, SO₂, CH₄, NH₃, O₂) | On-site diagnostics, mobile testing |

| NDIR Gas Analyzer | Robust, interference-free CO/CO₂/CH₄ detection | Combustion efficiency, incinerators |

| UV-DOAS Module | Real-time SO₂, NO, Cl₂, NH₃, H₂S detection | Environmental monitoring, CEMS |

| TDLAS Analyzer/Module | Ultra-precise, ppb detection, no cross-interference | NH₃ slip monitoring, HCl in cement, CH₄ in biogas |

| Syngas Analyzer | Simultaneous H₂, CO, CO₂, CH₄, CₙHₘ analysis | Gasification plants, steel mills |

| Greenhouse Gas Analyzer | Measures CO₂, CH₄, N₂O | Research, agriculture, carbon monitoring |

| CEMS Solution | Full-stack compliance system with calibration, data logging, and alerts | Power plants, industrial stacks |

Where Are Exhaust Gas Analyzers Used?

From Stacks to Labs—ESEGAS Covers It All

Exhaust gas analyzers have a broad array of applications. Here’s how ESEGAS analyzers serve different industries:

- Power Plants / Boilers / Combustion Stacks

- Measure CO₂, NOₓ, SO₂, O₂ for emissions monitoring

- Ensure CEMS compliance and boiler tuning

- Reduce fuel consumption and improve combustion efficiency

- Steel, Cement, and Petrochemical Plants

- High-temp and corrosive gas monitoring (e.g., HF, HCl, NH₃)

- Improve process safety and reduce emissions

- Biogas and Syngas Facilities

- Optimize gas composition for energy yield

- Continuous analysis of CH₄, H₂, CO, CO₂

- Environmental Monitoring Stations

- Detect greenhouse gas emissions and urban air pollutants

- Use portable and fixed stations for AQMS

- Laboratories and R&D Institutions

- Employ multi-gas portable devices for flexible analysis

- High precision for academic and compliance research

- OEM and System Integrators

- Integrate UV-DOAS and TDLAS modules into custom systems

- Support automation, industrial IoT, and remote diagnostics

How to Choose the Right ESEGAS Analyzer for Your Application?

Selecting the Wrong Tool Could Cost You—Here’s How to Get It Right.

When selecting an exhaust gas analyzer, consider:

- Gas Types to Be Measured: Are you monitoring toxic gases, GHGs, or syngas?

- Concentration Levels: Do you need ppm, ppb detection, or high-range measurements?

- Application Environment: Portable vs fixed, indoor vs stack-mounted

- Compliance Needs: Local emission standards and CEMS compliance

- Maintenance and Calibration: Availability of auto-calibration, diagnostics

- Integration: Compatibility with SCADA, PLC, or other control systems

ESEGAS offers custom configuration support and modular analyzers, making it easy to match technology to your unique requirements.

Conclusion: Choose Smart, Stay Compliant, Measure Precisely

An exhaust gas analyzer is more than a tool—it’s your gateway to regulatory compliance, process optimization, and environmental responsibility. With advanced technologies like TDLAS, NDIR, and UV-DOAS, and a broad product line supporting multi-gas portable usage, ppb detection, and full CEMS compliance, ESEGAS is positioned as a trusted partner for industries aiming to future-proof their gas analysis needs.