Enter a world of high-end gas analysis. Delve deep into Portable NH3 Laser Gas Analyzers. Grasp their working principles, components, and types. Understand their applications, features, and benefits. Know the factors that impact their accuracy. This guide illuminates each aspect.

Principles of Portable NH3 Laser Gas Analyzers!

1. Understanding NH3 (Ammonia) Gas

Ammonia or NH3 is a common industrial gas. In large amounts, it becomes a risk. Monitoring is vital. Portable NH3 Laser Gas Analyzers provide that function.

They detect and measure NH3 levels quickly. This makes them key safety tools in industries like agriculture and refrigeration.

2. Overview of Laser-based Gas Analysis

Laser-based gas analysis offers high accuracy. The key lies in the use of light. The analyzer’s laser shines light through a gas sample. The sample absorbs some of the light.

The remaining light intensity gives the NH3 concentration. The process is quick and efficient. It ensures real-time data, which is crucial for safety.

3. NH3 detection by Laser Gas Analyzers

Laser Gas Analyzers are specific in NH3 detection. NH3 molecules have unique light absorption characteristics. The laser’s wavelength is chosen for that.

It is sensitive only to NH3 absorption. This way, the readings are not affected by other gases. This specificity makes the devices reliable and precise.

4. The specificity of these devices to NH3

The Portable NH3 Laser Gas Analyzers stand out for their NH3 specificity. NH3 has a distinctive light absorption. The analyzer’s laser is attuned to this.

This means it only responds to NH3. Other gases will not interfere with the readings. Hence, you get accurate and reliable results every time.

Components of Portable NH3 Laser Gas Analyzers!

- Laser Module: The device’s heart. The module emits the laser beam. It uses a specific wavelength for NH3 detection.

- NH3 Sensor: The detection unit. It responds only to NH3. It helps ensure high accuracy in readings.

- Optical Chamber: The laser beam and gas sample interact here. The chamber’s design guarantees efficient light absorption.

- Detection Circuit: It processes the data from the sensor. The circuit converts light intensity to NH3 concentration.

- Power Supply: Energizes the system. Ensures smooth operation of all components.

- Data Logger: Keeps track of all measurements. It helps in long-term trend analysis.

- Interface Panel: The user’s touch point. Allows for easy device setup and data readout.

- Analog-to-Digital Converter: Translates sensor data to a digital format. This enables easy data handling and analysis.

- Gas Inlet and Outlet: These channels regulate the gas flow. They ensure that fresh samples reach the optical chamber.

- Signal Processor: Interprets data from the detection circuit. It helps derive the final NH3 concentration values.

- Sample and Reference Cells: The sample cell holds the gas. The reference cell contains a non-absorbing gas. Their comparison gives the NH3 level.

- Calibration Unit: Ensures accuracy in measurements. Regular calibration is key for precise readings.

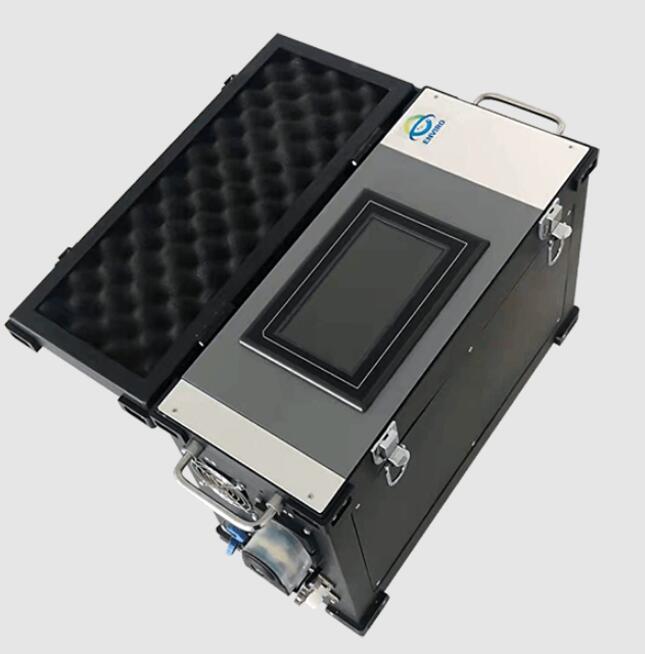

- Enclosure Case: Protects the internal parts. It also enhances portability and durability of the device.

Working Mechanism of Portable NH3 Laser Gas Analyzers!

1. Gas Ingestion

Portable NH3 Laser Gas Analyzers start their operations with gas ingestion. The instrument ingests ambient gas for analysis, a procedure vital for achieving accurate results.

2. Laser Emission

Subsequently, a laser emits a light beam. That laser targets the ingested gas, serving as the primary source of excitation for the gas sample.

3. Sample Excitation

The emitted laser beam excites the gas sample. Laser radiation is absorbed, resulting in a transformation of energy within the sample.

4. Signal Detection

The instrument then detects signals. The change in energy from the excitation step provides signals that the device’s sensors pick up.

5. Data Analysis

Once signals are detected, the next step involves data analysis. The analyzer processes the signals to extract meaningful data about the gas composition.

6. Ammonia Identification

Here, the device identifies the presence of ammonia. The unique signature of NH3 in the data enables its identification in the sample.

7. Gas Purging

After analysis, the device purges the gas. This ensures the gas chamber is ready for the next sample.

8. Laser Modulation

To achieve accurate readings, the device modulates the laser. This means altering its intensity or frequency to match the sample’s requirements.

9. Absorption Measurement

The next step involves absorption measurement. The device measures the degree of laser radiation absorbed by the gas sample, indicating the concentration of NH3.

10. Result Display

The analyzer then displays results. These are the final concentration values of NH3 in the analyzed gas sample.

11. Calibration

Periodic calibration ensures the device maintains accuracy. This involves comparing its results against known standards.

12. Data Logging

To track gas concentration over time, the analyzer logs data. This enables trends and patterns to be identified.

13. Auto Zeroing

Auto zeroing occurs to maintain accuracy. This function resets the device before each measurement.

14. Maintenance Reminder

To ensure the device’s longevity and consistent performance, maintenance reminders are included.

15. Error Detection

Finally, the analyzer has an error detection mechanism. This helps identify and resolve issues that might affect the device’s operation.

| Step | Working Mechanism | Relevant Components | Key Process | Duration |

| Gas Ingestion | Gas enters the device | Inlet port, Pump | Ingestion | Few seconds |

| Laser Emission | Laser emits light | Laser Diode | Emission | Instant |

| Sample Excitation | Laser light excites the sample | Chamber, Laser | Excitation | Milliseconds |

| Signal Detection | Detector senses excited sample | Detector | Detection | Few milliseconds |

| Data Analysis | Analyzer processes the signal | Microprocessor | Processing | Sub-seconds |

| Ammonia Identification | Analyzer identifies NH3 | Software | Identification | Instant |

| Gas Purging | Purges the analyzed gas | Outlet port | Purging | Few seconds |

| Laser Modulation | Modulates laser for precision | Laser Diode | Modulation | Instant |

| Absorption Measurement | Measures light absorption | Detector, Software | Measurement | Few milliseconds |

| Result Display | Displays analysis result | Display unit | Visualization | Instant |

| Calibration | Adjusts for accurate readings | Microprocessor, Software | Calibration | Few minutes |

| Data Logging | Stores analysis results | Memory unit | Storage | Instant |

| Auto Zeroing | Resets device reading | Microprocessor, Software | Zeroing | Few seconds |

| Maintenance Reminder | Signals device maintenance needs | Software | Reminder | Instant |

| Error Detection | Flags any system issues | Software, Error codes | Detection | Instant |

Types of Portable NH3 Laser Gas Analyzers!

1. Diode-based

These devices use semiconductor lasers for gas detection, offering high efficiency and compact size.

2. Quantum Cascade

Quantum Cascade Analyzers offer high sensitivity and precision, working particularly well in mid-infrared region.

3. Differential Absorption

This type uses the difference in absorption rates of different gases to identify and quantify them.

4. Tunable Diode

Tunable Diode Analyzers allow for the continuous tuning of the laser wavelength, providing high selectivity and sensitivity.

5. Raman Scattering

These devices utilize the Raman scattering effect to detect gases, offering high specificity.

6. Near-infrared

Near-infrared analyzers operate in the near-infrared region, effective for gases that absorb light in this range.

7. Mid-infrared

Mid-infrared analyzers are ideal for detecting gases with absorption peaks in the mid-infrared spectrum.

8. FTIR Spectroscopy

These use Fourier-transform infrared spectroscopy for comprehensive gas analysis, providing detailed spectral data.

9. UV Spectroscopy

UV Spectroscopy Analyzers work in the ultraviolet range and are suitable for gases that absorb UV light.

10. Optical Parametric

These analyzers utilize optical parametric oscillators, offering wide tunability and high power.

11. Mode-locked

Mode-locked analyzers provide ultrashort pulses, used in time-resolved gas detection applications.

12. Continuously Tunable

Continuously Tunable Analyzers can vary the laser wavelength during operation, enhancing gas detection range.

13. Ultrafast Pulsed

These provide extremely short light pulses, allowing for fast and precise gas analysis.

14. Frequency-locked

Frequency-locked analyzers maintain a constant laser frequency, ensuring stable operation.

15. Integrated Optical

These combine various optical components into a single device, offering compactness and integration ease.

Applications of Portable NH3 Laser Gas Analyzers!

1. Environmental Monitoring

Portable NH3 Laser Gas Analyzers aid in assessing ambient air quality. By recording NH3 levels, critical data helps maintain ecological balance, mitigating environmental harm.

2. Industrial Safety

Factories utilize these devices for safeguarding workers. They detect NH3 leaks, minimizing exposure risk, and ensuring workplace safety.

3. Agriculture

Farmers use these tools to measure soil NH3 levels. Also, precise NH3 monitoring aids in maintaining optimal crop health, boosting yield, and improving food security.

4. Food Processing

Food industries value these analyzers for detecting NH3 in preservation systems. By ensuring safety standards, quality control becomes less daunting, enhancing consumer trust.

5. Waste Management

Landfill operators use these tools for tracking NH3 emissions. Accurate detection assists in environmental compliance, reducing the potential for ecological damage.

6. Power Plants

In power generation facilities, NH3 measurement is crucial. The detection and management of NH3 emissions enhance plant efficiency and minimize environmental impact.

7. Pharmaceuticals

The pharmaceutical industry uses these analyzers to detect NH3 during drug production. Reliable monitoring safeguards product purity, assuring medicinal effectiveness.

8. Refrigeration Systems

These devices offer essential NH3 leak detection in refrigeration units. Rapid identification of NH3 leakage avoids equipment damage, extending the lifespan of cooling systems.

9. Chemical Plants

Chemical manufacturers harness these tools for maintaining NH3 levels. They ensure production safety, fostering a healthier industrial environment.

10. Livestock Farms

On livestock farms, these analyzers monitor NH3 in animal waste. By controlling NH3 levels, farmers maintain animal health, promoting agricultural productivity.

11. Air Quality Testing

These devices are integral to air quality analysis. They measure ambient NH3, helping authorities devise informed air quality management strategies.

12. Greenhouse Gas Monitoring

To combat climate change, these tools monitor greenhouse gases. They detect NH3, one of the key contributors to global warming.

13. Chemical Warfare Detection

In military and defense sectors, these analyzers are pivotal. They detect NH3 in chemical weapons, providing early warning and protecting lives.

14. Marine Emissions Monitoring

Ships use these devices to measure exhaust gas emissions. By tracking NH3 levels, they comply with international maritime regulations, protecting marine ecosystems.

15. Hazardous Material Management

These analyzers find use in hazardous material handling. They ensure safety by detecting NH3 leaks, protecting workers and the environment alike.

Key Features and Capabilities of Portable NH3 Laser Gas Analyzers!

1. High Sensitivity

Critical to all Portable NH3 Laser Gas Analyzers is their extraordinary sensitivity. They detect even minute quantities of NH3 gas, providing precise readings in challenging environments.

2. Broad Range

Such analyzers come equipped with a wide detection range. As a result, they effectively monitor NH3 levels across diverse settings, whether industrial or environmental.

3. Rapid Response

Their fast response time is impressive. Within seconds, they detect and report NH3 levels, ensuring swift actions to maintain safety standards.

4. Real-time Analysis

These devices provide continuous, real-time NH3 monitoring. Consequently, you receive up-to-date information on gas levels, helping prevent hazardous situations.

5. Portability

These are compact, lightweight, and easily transportable. Hence, they offer flexibility in usage, suitable for both stationary and mobile applications.

6. High Resolution

With superior resolution, they ensure precise NH3 measurements. Such clarity facilitates accurate data interpretation, critical for safety and regulatory compliance.

7. Low Drift

These analyzers exhibit minimal drift over time, guaranteeing reliable results even after extended use. Hence, accuracy remains uncompromised.

8. Data Logging

They feature advanced data logging capabilities. Hence, you can track and review NH3 levels over extended periods, enabling pattern analysis and preventive measures.

9. User-friendly Interface

These analyzers come with intuitive, easy-to-navigate interfaces. As a result, operations are straightforward, reducing the likelihood of user error.

10. Robust Construction

The sturdy build of these devices withstands harsh conditions, enhancing longevity. Thus, despite being portable, they are robust and dependable.

11. Wireless Connectivity

Incorporating wireless technology, they allow remote monitoring and control. Consequently, you can manage operations with greater ease and efficiency.

12. High Accuracy

These devices excel in providing accurate NH3 measurements. Precise data supports informed decision-making, crucial in risk-prone environments.

13. Calibration Capabilities

Equipped with calibration functions, they ensure measurement accuracy is maintained over time. Calibration is a must for ensuring continual reliable operation.

14. Battery Powered

Being battery-powered, they offer operational flexibility. Battery power enables usage in remote locations, free from reliance on grid electricity.

15. Multi-gas Detection

Some analyzers are capable of detecting multiple gases. Hence, they provide comprehensive monitoring, strengthening safety measures in various industries.

Practical Benefits of Using Portable NH3 Laser Gas Analyzers!

1. Safety Enhancement

These devices improve safety by providing real-time data about ammonia levels in the air. A sudden rise in NH3 levels signals potential danger, enabling prompt action to protect personnel.

2. Efficient Monitoring

Accurate and efficient monitoring is another core advantage. With advanced laser technology, these analyzers deliver precise readings, monitoring even trace levels of NH3.

3. Cost Savings

Regular and efficient monitoring of gas levels can lead to significant cost savings. Rapid detection of changes in gas concentration reduces the risk of costly equipment damage and operational downtime.

4. Regulatory Compliance

Maintaining regulatory compliance is vital in industries using hazardous gases. The device ensures industries meet regulatory standards, helping them avoid hefty fines and sanctions.

5. Early Leak Detection

The device’s high sensitivity allows for early detection of gas leaks. It mitigates potential hazards and prevents the escalation of minor issues into major incidents.

6. Process Optimization

By continuously tracking gas concentration, the device facilitates process optimization. Accurate data helps industries fine-tune their operations, leading to better resource utilization and increased efficiency.

7. Environmental Protection

Minimizing gas leaks reduces the environmental impact of industrial operations. The analyzers support green initiatives, contributing to the global effort to protect the environment.

8. Reduced Downtime

Unplanned downtime can be costly. By enabling early detection of potential issues, these devices minimize downtime and ensure smooth operation of industrial processes.

9. Improved Decision Making

Having accurate data at disposal can aid in making informed decisions. It provides valuable insights into system performance and helps identify areas for improvement.

10. Increased Productivity

Enhanced safety, better compliance, optimized processes, and reduced downtime collectively lead to increased productivity. Accurate monitoring of NH3 levels creates a safer work environment, boosting workers’ morale and productivity.

11. Remote Operation

The NH3 portable laser gas analyzer allows for remote operation, enhancing convenience and safety. Operators can monitor gas levels without being physically present at the site.

12. Reduced Emissions

Lowering gas emissions is vital for environmental sustainability. By facilitating early leak detection and efficient monitoring, these devices significantly reduce harmful emissions.

13. Risk Mitigation

Risk mitigation is a primary benefit of using these devices. Quick detection of gas leaks helps mitigate potential risks, improving safety and operational efficiency.

14. Data Accessibility

These analyzers provide easily accessible data in real-time, crucial for maintaining optimal operations. Access to real-time data facilitates quick response times to any potential issues.

15. On-Site Analysis

The portability of these devices allows for on-site analysis, making it possible to get immediate and accurate readings. This capability eliminates the need for sample collection and subsequent laboratory analysis, enhancing efficiency.

Conclusion

Portable NH3 Laser Gas Analyzers lead the way in precise gas detection. They combine accuracy with versatility, providing immense benefits. The range of applications is wide, from safety to environmental protection. Consider exploring more at ESEGAS. Harness the power of advanced gas analysis today.