Industrial plants struggle with strict emission laws. Inaccurate readings risk fines and shutdowns. ESEGAS analyzers solve this with real-time, reliable industrial gas analyzer for stack emission monitoring.

Industrial gas analyzers play a critical role in stack emission monitoring, ensuring regulatory compliance by measuring key pollutants like NOx, SO₂, CO, and CO₂ in real time.

Even after knowing the benefits, selecting the right analyzer and understanding its mechanisms is essential for long-term success and environmental responsibility.

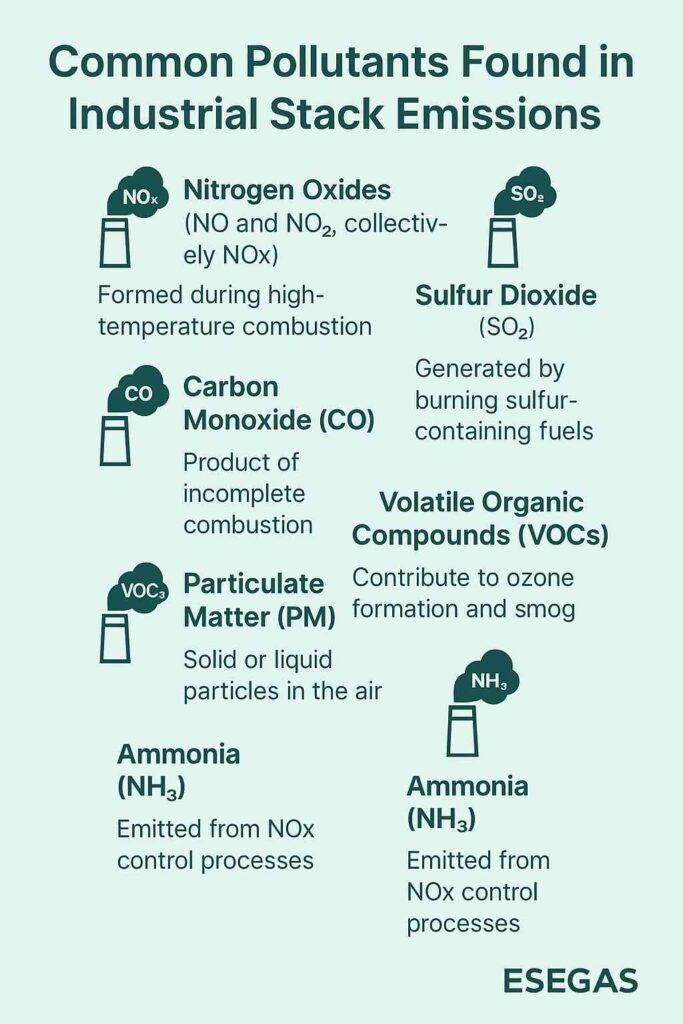

What Are the Common Pollutants Found in Industrial Stack Emissions?

Invisible gases often pose the greatest environmental and regulatory threats.

Industrial stack emissions typically contain a mix of harmful gases and particulates that directly impact air quality and climate. ESEGAS analyzers are specifically engineered to detect the most critical pollutants, including:

- Nitrogen Oxides (NO and NO₂, collectively NOx):

Formed during high-temperature combustion, NOx gases contribute to smog formation and respiratory problems. They also play a role in acid rain and ground-level ozone.

- Sulfur Dioxide (SO₂):

Generated from burning sulfur-containing fuels like coal or oil, SO₂ causes acid rain and aggravates lung conditions. It’s a tightly regulated pollutant in most jurisdictions.

- Carbon Monoxide (CO):

A product of incomplete combustion, CO is colorless and odorless but highly toxic. In addition to safety concerns, CO emissions often signal poor combustion efficiency.

- Carbon Dioxide (CO₂):

While not toxic at low concentrations, CO₂ is a major greenhouse gas. Monitoring CO₂ is crucial for carbon footprint reporting and voluntary or mandatory emission reduction programs.

- Volatile Organic Compounds (VOCs):

VOCs include a wide variety of hydrocarbon-based gases that contribute to ozone formation and smog. Many are carcinogenic and subject to strict reporting thresholds.

- Particulate Matter (PM):

These solid or liquid particles can carry heavy metals or toxic compounds. They contribute to haze and pose respiratory risks. Stack analyzers often integrate PM monitors for complete compliance.

- Ammonia (NH₃):

Common in processes using selective catalytic reduction (SCR) for NOx control, ammonia slip must be measured to prevent secondary pollution.

ESEGAS systems are designed to detect these pollutants with high sensitivity and stability, enabling industries to stay compliant with international emission standards while protecting environmental and human health.

How Does a Gas Analyzer Accurately Monitor Emissions in Real Time?

Manual sampling is unreliable and too slow for today’s emission standards.

Modern industrial gas analyzers—like those developed by ESEGAS—use cutting-edge sensor technologies and automation to provide continuous, accurate measurements of stack emissions. These systems typically operate in one of two configurations: in-situ or extractive.

Here’s how they work:

- Gas Sampling & Conditioning:

In extractive systems, a probe draws flue gas from the stack. The sample is filtered, cooled, and conditioned to remove particulates and moisture—essential steps for precise measurement. In-situ systems, on the other hand, measure directly within the stack without extracting gas, minimizing response time.

- Detection Technologies:

ESEGAS analyzers integrate various detection principles based on gas type:

- NDIR (Non-Dispersive Infrared): Ideal for CO, CO₂, and hydrocarbons, this method detects gas concentration based on infrared absorption.

- Electrochemical Cells: Used for detecting NOx and O₂, these sensors measure voltage changes caused by gas interaction.

- Paramagnetic Detectors: Highly accurate for O₂ measurement, using magnetic properties of oxygen molecules.

- FTIR (Fourier Transform Infrared): A broadband method capable of measuring multiple gases simultaneously, useful for complex emission profiles.

- Data Processing & Output:

Real-time data is digitized, analyzed, and transmitted to a central control system or cloud dashboard. Operators can monitor trends, receive alerts, and even automate burner or SCR adjustments for emission control.

- Calibration & Self-Diagnostics:

ESEGAS units feature automatic calibration using built-in reference gases and perform routine self-checks to ensure sensor integrity. This guarantees consistent performance over long operational periods, even in harsh conditions.

With this combination of precise sensing, intelligent processing, and robust construction, ESEGAS analyzers help industries meet strict emission limits while optimizing plant performance.

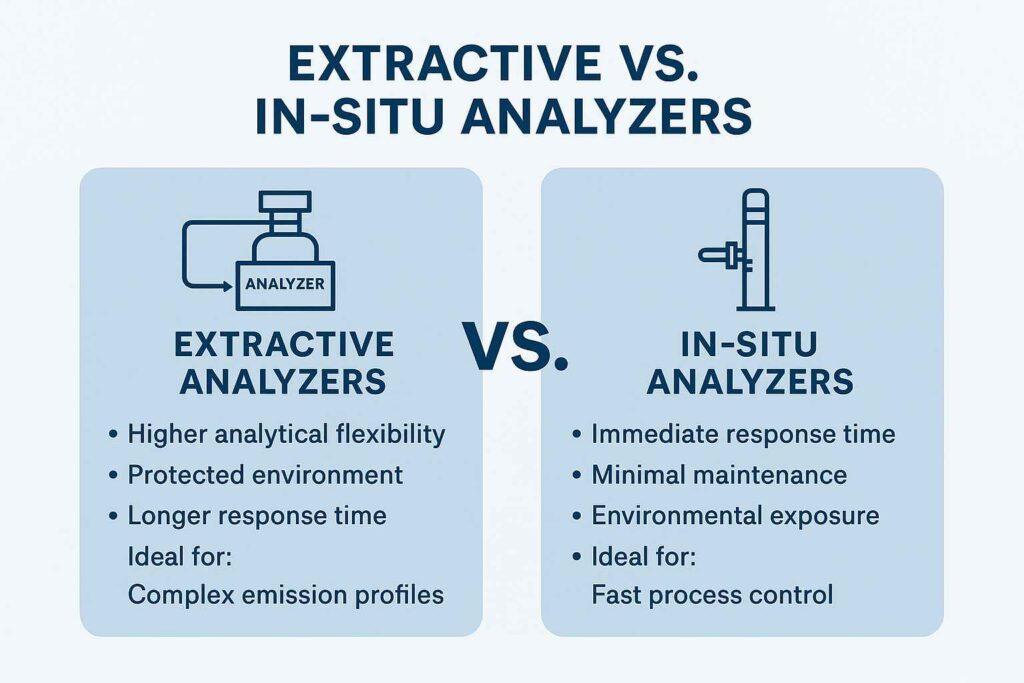

What’s the Difference Between Extractive and In-Situ Analyzers?

Choosing the wrong type of analyzer can lead to inaccurate data and high maintenance costs.

Extractive Analyzers

These systems physically extract gas samples from the stack via a probe. The gas is transported through heated lines to a remote analysis cabinet where it’s filtered, dried, and then analyzed.

Key Features:

- Higher analytical flexibility: Capable of multi-gas and high-precision measurements.

- Protected environment: Sensors are housed away from corrosive stack conditions.

- Longer response time: Due to gas transport and conditioning delays.

- Ideal for: Complex emission profiles (e.g., waste incineration, chemical plants).

In-Situ Analyzers

In contrast, in-situ analyzers are installed directly on the stack, with sensors exposed to the flue gas in real time. They either work point-style (probe in the gas stream) or cross-stack (beam across the duct).

Key Features:

- Immediate response time: No sample transport delays.

- Minimal maintenance: No sampling lines or pumps.

- Environmental exposure: Sensors must withstand high temperature, dust, and corrosives.

- Ideal for: Fast process control (e.g., cement kilns, steel furnaces).

If you need detailed, multi-component analysis with flexibility, extractive systems are preferable. For fast feedback and low maintenance, in-situ is the go-to. ESEGAS helps clients evaluate their process environment to choose the most cost-effective and reliable solution.

How Can You Maintain Long-Term Accuracy in Emission Monitoring?

Even the best analyzers drift over time without proper maintenance and calibration.

Maintaining high accuracy in stack emission monitoring is a continuous challenge due to sensor aging, environmental stress, and contamination. To ensure regulatory compliance and data integrity, plants must adopt a proactive maintenance strategy. ESEGAS analyzers are engineered to support long-term precision through several key features and best practices:

1.Scheduled Calibration

Regular calibration against certified reference gases corrects sensor drift and maintains measurement credibility. ESEGAS systems feature automatic or semi-automatic calibration routines, reducing reliance on manual intervention.

2.Built-In Self-Diagnostics

Advanced diagnostic algorithms monitor internal parameters such as optical clarity, flow rates, and temperature drift. These systems alert operators before critical faults occur, enabling preventive maintenance rather than reactive downtime.

3.Sample Conditioning Systems

For extractive analyzers, clean and stable samples are essential. Filters, moisture traps, and heated lines prevent fouling. ESEGAS integrates robust sample handling modules tailored for harsh flue gas compositions.

4.Remote Monitoring & Alerts

Modern ESEGAS platforms include cloud-connected dashboards and smart alarms. Operators can access analyzer status in real time, minimizing unplanned downtime and ensuring continuous performance verification.

5.Routine Maintenance Protocols

Periodic cleaning of optical paths, checking of flow meters, and replacement of wear parts extend the analyzer’s lifespan. ESEGAS provides detailed maintenance schedules and kits to streamline these tasks.

Conclusion

Industrial stack emissions demand precise, reliable monitoring. ESEGAS analyzers deliver the compliance, performance, and durability modern facilities need.