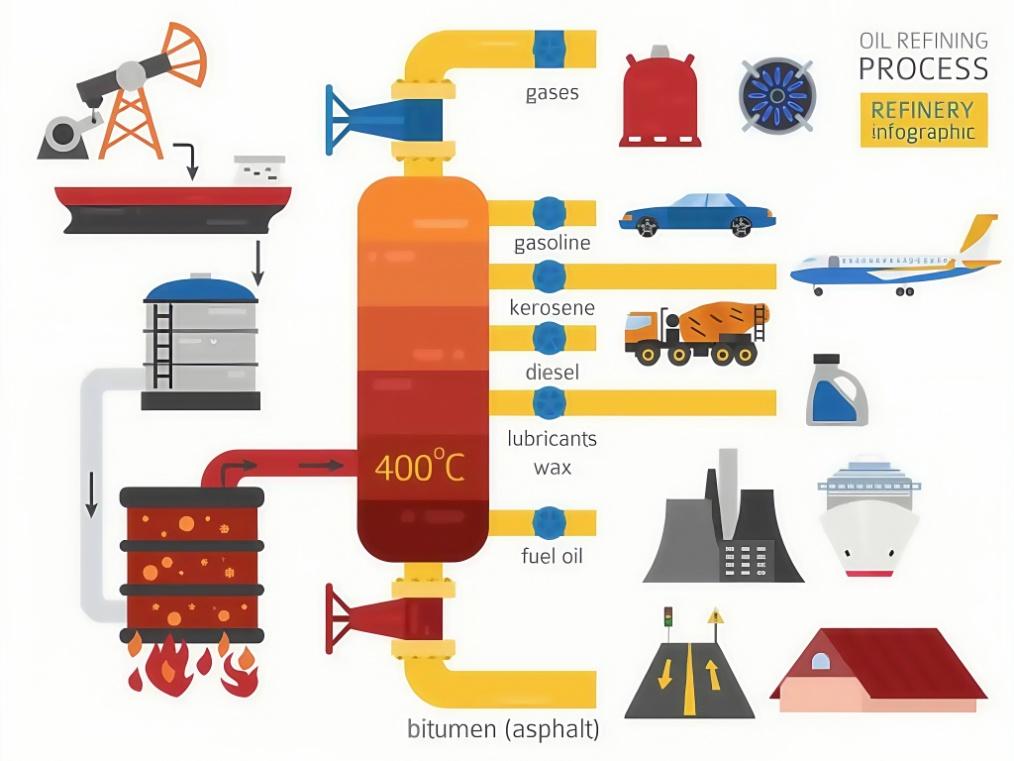

Refining operations are complex, high-stakes environments where gas composition plays a pivotal role in product quality, process efficiency, safety, and regulatory compliance. In this environment, process gas analyzers offer a vital tool for continuous, real-time, and wide range insight. From combustion control to hydrogen purity monitoring, these instruments optimize operations by enabling data-driven decisions.

In this article, we break down the specific ways gas analyzers enhance the refining process, focusing on practical insights for engineers and operators aiming to improve performance, reduce waste, and meet increasingly stringent emission standards.

What Is the Role of a Process Gas Analyzer in Refining Gas Monitoring?

Why Gases Matter in Refining

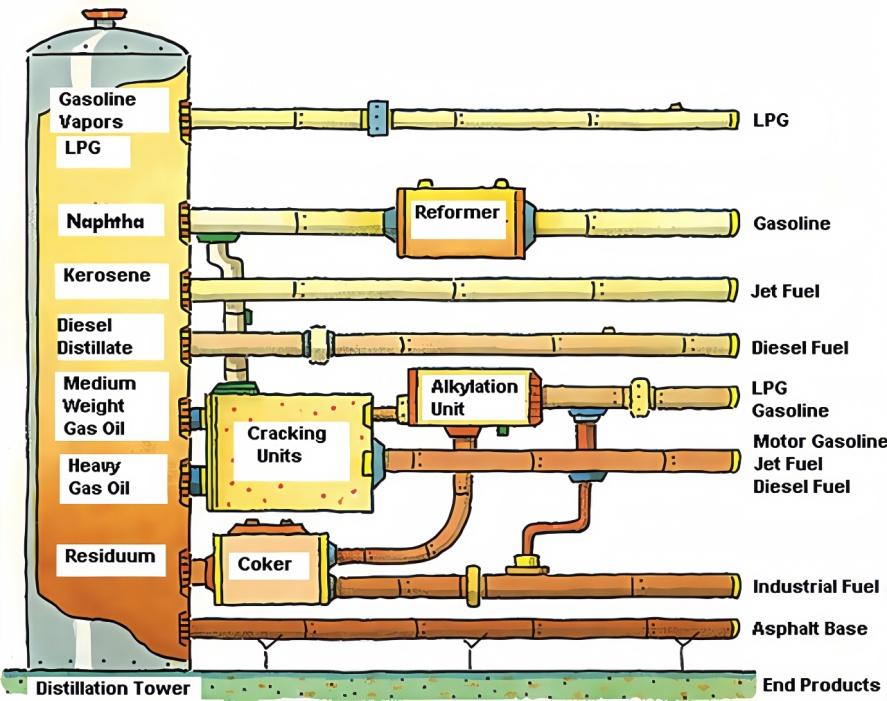

Refining involves many gas-dependent steps—distillation, cracking, reforming, and treating. Gases like O₂, CO, CO₂, H₂, H₂S, and CH₄ directly impact:

- Safe combustion—improper O₂ or CO levels can spark fire hazards.

- Optimal reaction yields—hydrogen and hydrocarbons drive key reactions.

- Catalyst protection—trace H₂S or O₂ contamination deactivates catalysts.

- Emissions control—CO, NOₓ, and sulfur species affect compliance.

Moreover, gas composition can shift fast due to feed mix changes, temperature swings, and equipment wear. Without real-time data, a small swing in H₂S or CO₂ might go unnoticed—triggering off-spec products, unsafe conditions, or fines. So, gas analyzers serve as your process early-warning system.

Traditional vs. Real-Time Monitoring

In the past, many refineries relied on manual grab samples or lab analysis. Such methods are slow, error-prone, and reactive. A sample may take hours—or days—to process, by which time the issue is already affecting operations.

By contrast, process gas analyzers offer continuous, in-situ or extractive measurement directly at the source. That means you can:

- Detect issues instantly

- Feed live data into your DCS for dynamic control

- Reduce human error and sampling delay

This real-time capability means faster response, fewer deviations, and smarter decision-making at every refinery stage.

Which Key Refining Units Rely on a Process Gas Analyzer?

Refining operations involve complex gas reactions and precise control. A process gas analyzer plays a vital role in key units, ensuring efficient, safe, and compliant operation.

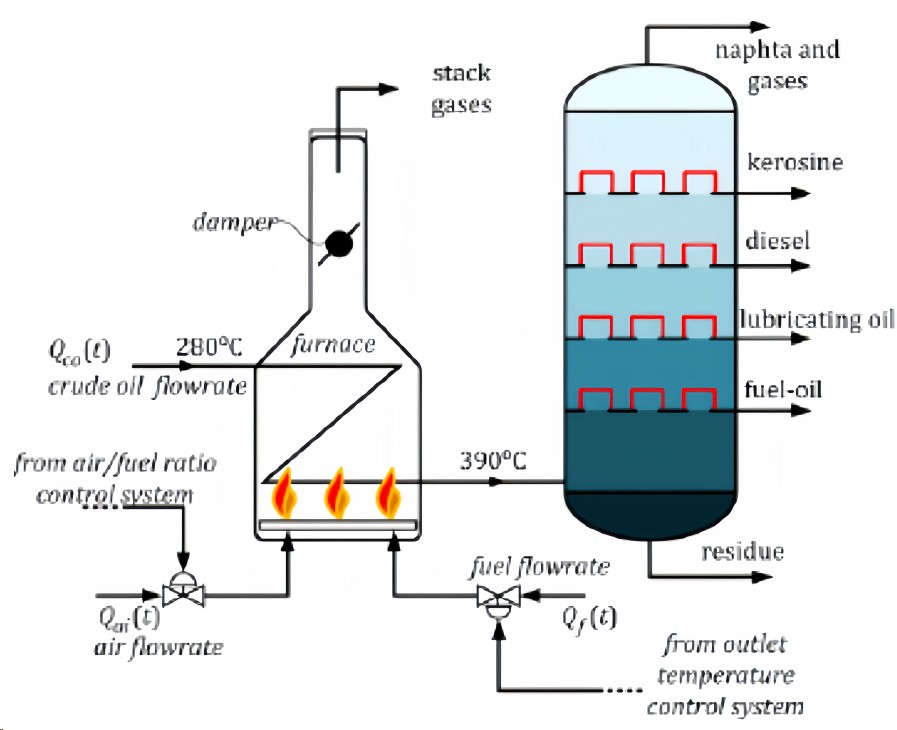

- Combustion Optimization in Furnaces and Boilers

(Crude oil preheating furnace)

In fired heaters and boilers, balancing the air-to-fuel ratio is essential. Too much oxygen wastes energy; too little creates carbon monoxide (CO), a safety and emissions issue. By installing an in-situ analyzer—such as zirconia or paramagnetic sensors for O₂, and NDIR analyzers for CO and CO₂—you can:

- Save fuel by trimming excess air

- Cut CO and NOₓ emissions for cleaner output

- Reduce costs tied to air and fuel inefficiency

How: Place O₂ and CO sensors in the flue gas stream. Their real-time data enables your control system to fine-tune burner settings, boosting efficiency and sustainability.

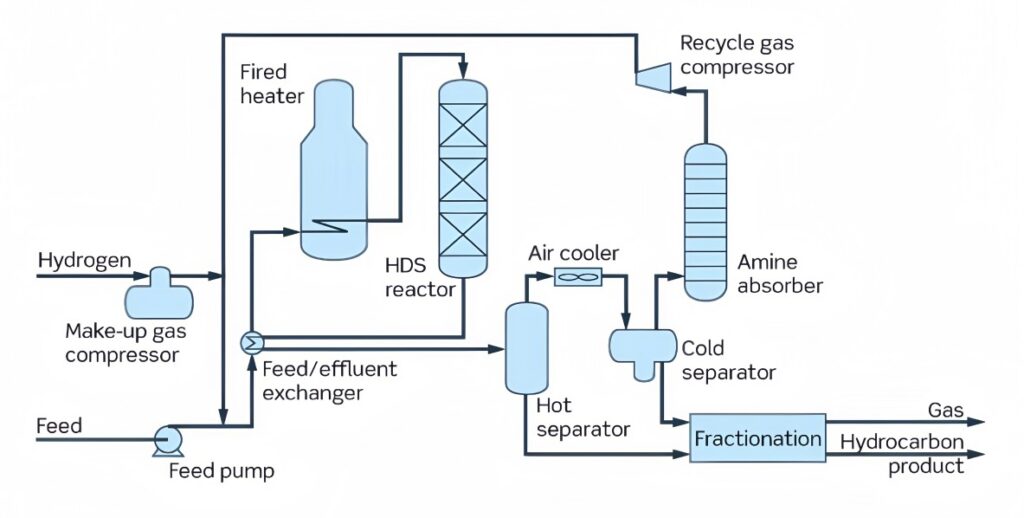

- Hydrogen Management in Hydrotreaters and Reformers

Hydrogen is essential for hydrotreating and reforming to remove sulfur, nitrogen, and saturate hydrocarbons. Losing track of hydrogen purity or concentration can deplete catalyst activity, reduce yield, and spike costs.

Use:

- TCD analyzers for real-time H₂ detection

- NDIR tools for tracking CO, CO₂, and CH₄

Benefits:

- Extend catalyst lifespan

- Prevent hydrogen waste

- Optimize H₂ consumption

Tip: Install TCD analyzers on both makeup and recycle H₂ lines to monitor purity and maintain process balance.

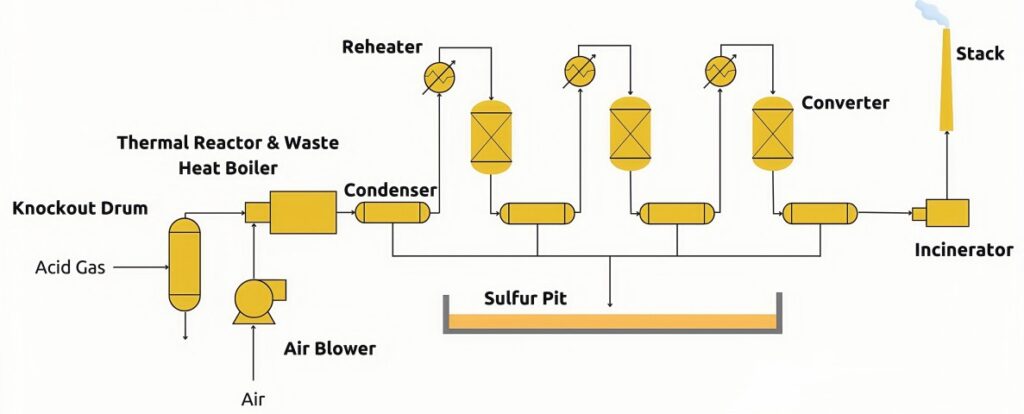

- Amine Gas Treating and Sulfur Recovery Units (SRUs)

(Sulfur Recovery Units (SRUs))

Managing acid gas levels (H₂S and CO₂) in amine units and SRUs is crucial. The right combination of acid gas and oxygen ensures effective sulfur recovery while avoiding corrosion.

Recommended analyzers:

- TDLAS or NDIR for H₂S and CO₂

- Electrochemical or paramagnetic sensors for O₂

- NDIR for SO₂

Benefits:

- Avoid overloading amine systems

- Maximize sulfur conversion efficiency

- Prevent corrosion and permit violations

Recommendation: Equip the SRU with TDLAS for fast H₂S detection and an O₂ sensor for air control—ensuring precision in combustion and recovery.

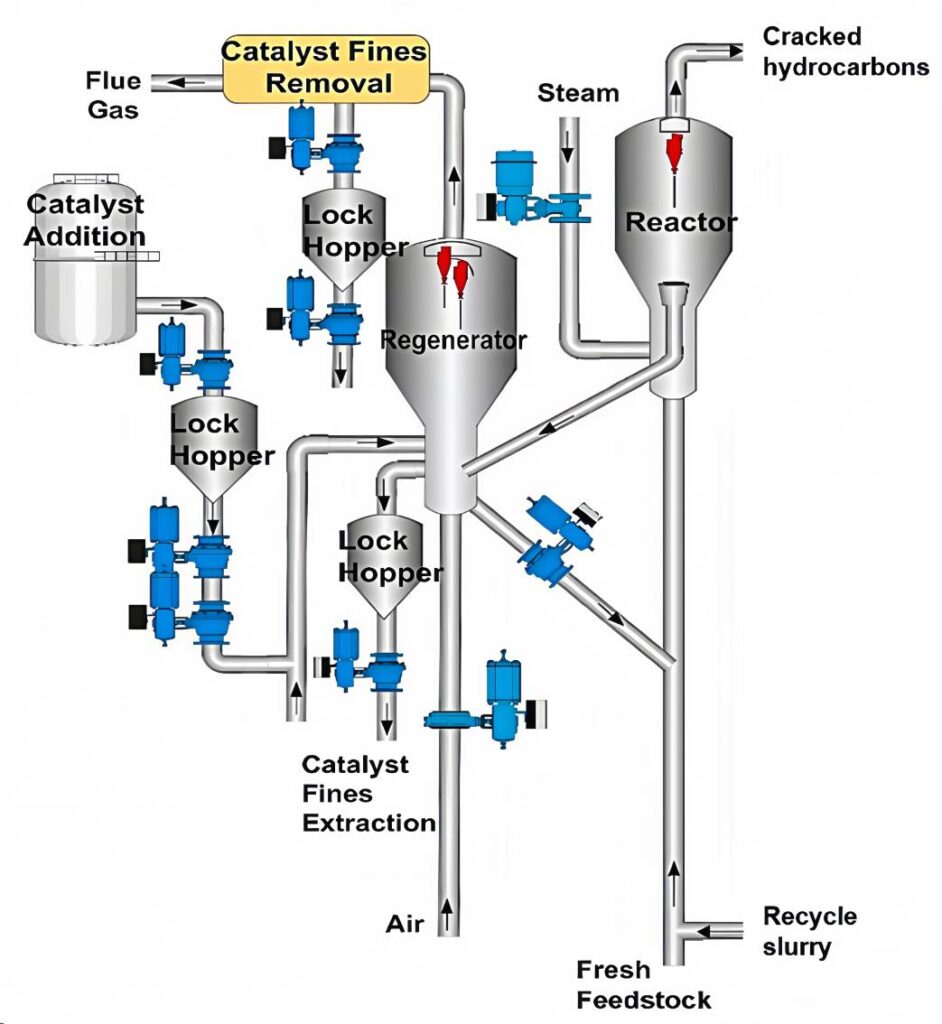

- FCC Units and Regenerators

In the fluid catalytic cracking (FCC) process, regenerators burn off coke deposits using a controlled combustion environment. The challenge is to fully oxidize coke without excessive CO slip.

Use continuous NDIR O₂ and CO, coupled with paramagnetic sensors.

Benefits:

- Prevent over- or under-airing

- Recover more heat

- Maintain catalyst effectiveness

Action: Monitor flue gas continuously to maintain a clean combustion environment in the regenerator, safeguarding catalysts and productivity.

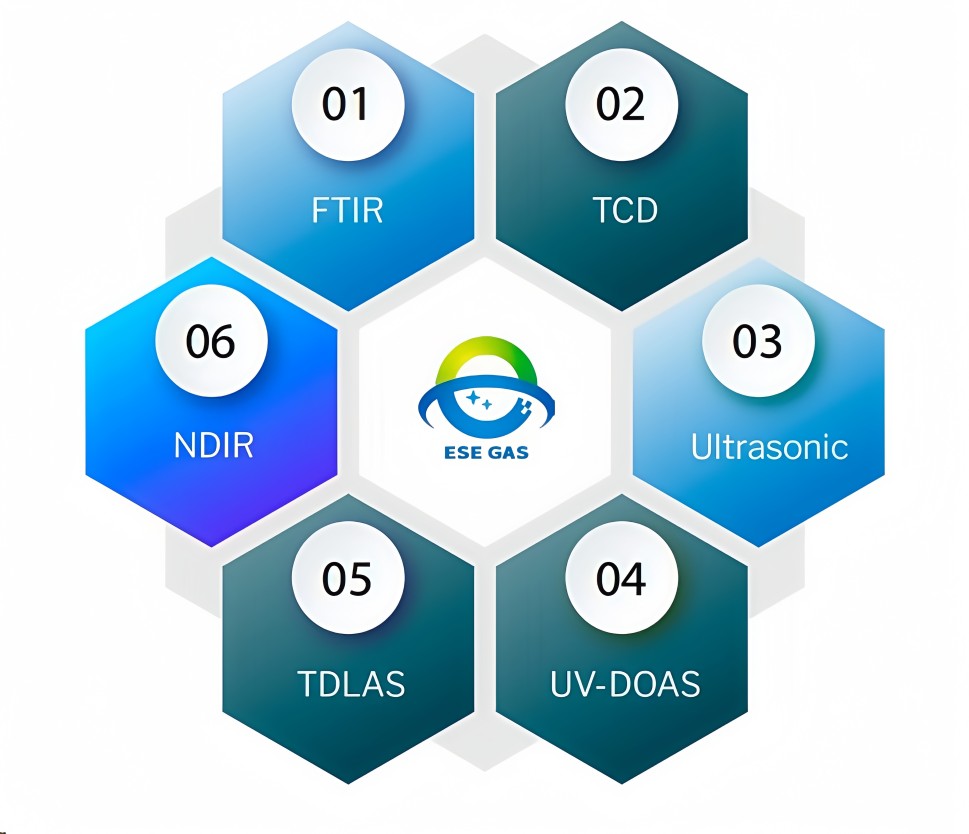

Which Analyzer Technologies Power Precision in Process Gas Analyzer Systems?

Precision in refining hinges on matching the right tool to the right job. Let’s unpack the core technologies behind effective process gas analyzer systems:

1.Tunable Diode Laser Absorption Spectroscopy (TDLAS)TDLAS offers targeted, ultra-sensitive measurements for gases like H₂S, H₂O, and NH₃. By scanning specific wavelengths that only the target gas absorbs, TDLAS delivers:

- Exceptional selectivity and sensitivity, down to ppb levels

- Fast, non-contact readings, ideal under harsh conditions

- Minimal drift, low upkeep, thanks to stable laser systems

Best applications: Sulfur Recovery Units (SRUs), amine treatment, catalytic reformers, and dusty or corrosive streams. In fact, many refineries now rely on TDLAS for moisture and H₂S monitoring in such critical areas

2.Non-Dispersive Infrared (NDIR)

NDIR sensors detect gases based on how they absorb infrared light. These systems are:

- Trusted and rugged, suited for everyday industrial use

- Capable of measuring CO, CO₂, CH₄, and H₂S

- Ideal for combustion optimization in boilers, FCC units, and general monitoring work

Though NDIR shines in reliability and simplicity, its sensitivity is typically in the ppm range—much less than TDLAS.

3.Thermal Conductivity Detector (TCD)

TCDs are workhorses for detecting hydrogen (H₂) because H₂ changes thermal conductivity significantly:

- Durable and inert, with no special optical parts

- Suits binary gas detection like hydrogen purity lines

- Common in hydrotreaters and reformers to monitor and protect catalysts from hydrogen shifts

4.Electrochemical and Paramagnetic Sensors for O2

For oxygen measurement, two sensor types dominate:

- Electrochemical cells: Sensitive with clear low-range detection

- Paramagnetic or quenched fluorescence sensors: Robust, interference-resistant

They deliver:

- Quick readings, helping control combustion air and SRU stoichiometry

- Stable calibration, even in H₂S and moisture environments

Both are essential for precise air–fuel balancing and avoiding combustion upsets.

How Do Process Gas Analyzers Improve Refining Performance?

Process gas analyzers aren’t just measurement tools—they drive operational excellence. Here’s how they elevate refinery performance:

1.Process Efficiency

Process gas analyzers help you:

- Fine-tune combustion by monitoring O₂ and CO in real time to stay at peak thermal efficiency.

- Minimize hydrogen and hydrocarbon losses, ensuring tighter control of H₂ and CH₄ streams.

- Prevent over/under-treatment in amine sweetening units through accurate H₂S and CO₂ readings.

Outcome: You save on fuel, reduce chemical usage, and boost overall yield. Plus, you proactively spot inefficiencies before they cascade into bigger issues.

2.Product Quality

Real-time gas analysis ensures consistent product quality:

- You get instant feedback to avoid off-spec batches.

- You maintain tighter reaction control, reducing variability.

- You detect process drift early, enabling preventive fixes.

Outcome: Higher-quality output and reduced need for rework.

3.Equipment Protection & Reliability

Protecting assets is vital. Gas analyzers actively prevent damage:

- They shield catalysts from contamination—like O₂ ingress or sulfur sneak-in.

- They help stave off corrosion in amine units and piping.

- They detect leaks and disturbances before they escalate.

Outcome: Lower repair costs, fewer breakdowns, and longer equipment life.

4.Emissions Compliance

With stricter regulations, continuous monitoring is a must:

- Analyzers track key pollutants such as SO₂, NOₓ, CO, and H₂S.

- They seamlessly support CEMS and SCADA/DCS reporting systems.

- They enable real-time emission management—adjusting processes to stay compliant.

Outcome: You avoid fines, meet environmental standards, and support sustainability goals.

How Can You Integrate a Process Gas Analyzer Practically in Refining Operations?

Implementing a process gas analyzer requires thoughtful planning and system design. Here’s how to embed them effectively in your plant:

1.Where to Start

Begin with a strategic audit:

- Identify high-impact units such as furnaces, SRUs, reformers.

- Assess current monitoring methods and gaps.

- Prioritize gases with high variability or regulatory sensitivity (e.g., H₂S, CO, O₂).

By zoning in on critical areas, you can deploy analyzers where they deliver immediate returns.

2.Choosing the Right Analyzer

Pick instruments that match your actual process needs:

- Match gas type to technology: use TDLAS for trace H₂S or NDIR for routine CO monitoring.

- Consider lifecycle: weigh maintenance, calibration, and integration complexity.

- Decide installation style: choose in-situ for fast readings; go extractive when sample conditioning is needed.

Think holistically: analyzer choice affects performance, cost, and operability.

3.Maintenance and Calibration

Reliable data begins with regular upkeep:

- Schedule zero/span checks, daily or weekly based on spec and regulation.

- Use auto-calibration options to reduce human labor and errors

- Integrate into your DCS or SCADA for real-time visibility, alarm suppression, and record-keeping

Automation isn’t a bonus—it’s essential for compliance, safety, and operational insight.

4.System Integration and Sampling

Sampling systems matter just as much as analyzers:

- Use sturdy sampling lines and conditioning to prevent fouling and ensure representativity.

- Apply standards like NeSSI for modular, compact, and automated sample system design.

- Ensure tight integration with your DCS/SIS/PLC to trigger control logic based on analyzer outputs.

A smart sampling system allows for accurate, timely measurements—and builds the foundation for automated control.

5.Long-Term Operational Strategy

Think beyond installation:

- Track performance KPIs, such as uptime, drift trends, and calibration events via analyzer dashboards.

- Use analytics tools to flag early drifts or failures and transition from reactive to proactive maintenance.

- Review system ROI routinely: include energy savings, yield gains, emission reductions, and compliance benefits.

Conclusion

Process gas analyzers do more than just monitor gases—they transform refining operations from reactive to predictive. By using advanced technologies, operators gain real-time insight into critical gas streams. This insight drives: enhanced efficiency, superior product quality, robust reliability, and smooth compliance

Process gas analyzers are not optional—they’re essential for modern refining. When deployed thoughtfully, they deliver operational clarity, resilience, and value. The choice to invest in advanced gas analytics isn’t just smart—it’s strategic.

If you want to know more details, contact with us please!