Ultra-high purity gases demand impurity detection at ppb or ppt levels, making contamination control critical yet challenging. TDLAS offers a powerful solution by detecting trace molecules in real time, solving accuracy and speed issues in purity monitoring.

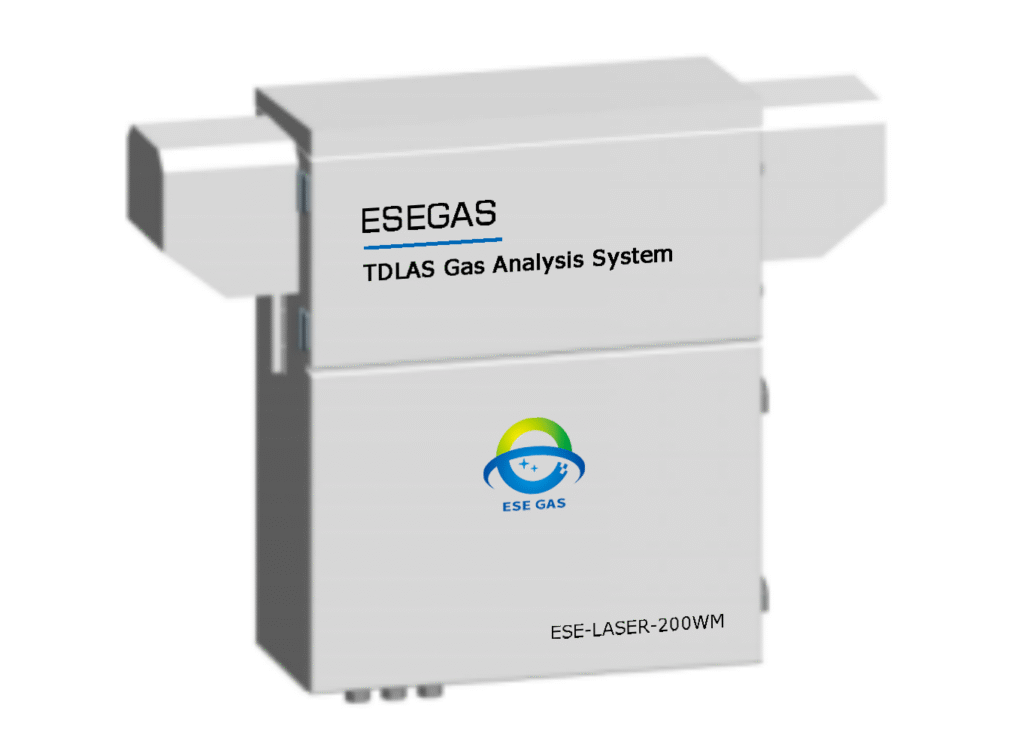

The ESEGAS TDLAS Gas Analysis System delivers ultra-high sensitivity and precision for real-time impurity monitoring in ultra-pure gas streams, crucial for semiconductor fabrication, photonics, and other high-tech industries.

Still wondering how ESEGAS’s TDLAS product works in practice or what advantages it brings? Let’s dive deeper into the critical Q&A sections to uncover its full potential.

Why is impurity monitoring in ultra-high-purity gases critical for advanced industries?

Ultra high purity (UHP) gases are foundational to advanced manufacturing sectors, including semiconductors, photovoltaics, and display technologies. However, even trace levels of contaminants—such as water vapor, hydrochloric acid (HCl), ammonia (NH₃), or oxygen—can compromise sensitive processes. These impurities, present in concentrations as low as parts per billion (ppb) or even parts per trillion (ppt), can cause dielectric breakdowns, chemical instability, corrosion, and defect formation in critical components like microchips and optical layers.

The margin for error in these environments is razor-thin. A momentary lapse in purity can lead to batch-level product rejection, wasted materials, and unplanned downtime. Traditional analytical techniques often fail to provide the speed, resolution, and selectivity necessary to detect these ultra low concentrations in real time. Without effective impurity monitoring, manufacturers face reduced yields, inconsistent quality, and increased costs—especially as device geometries shrink and production tolerances tighten.

To ensure product reliability and process efficiency, advanced industries require continuous, real-time monitoring of gas purity with ultra-low detection limits. This is where ESEGAS’s TDLAS product plays a vital role. By offering laser-based, non-invasive detection with sub-ppb sensitivity, the system enables precise identification and quantification of trace impurities before they reach critical thresholds. This empowers operators to make immediate corrective decisions, reduce scrap rates, and maintain compliance with the most demanding industry standards.

What makes TDLAS suitable for ultra-high purity gas analysis?

Monitoring trace-level impurities in ultra-high purity (UHP) gases requires extreme sensitivity, selectivity, and response speed. Conventional techniques—such as gas chromatography (GC), electrochemical sensors, or nondispersive infrared (NDIR) analysis—often struggle to meet these demands. They suffer from slow response times, limited specificity, high maintenance, and vulnerability to environmental drift.

In applications like semiconductor manufacturing, even a few seconds of undetected contamination can jeopardize an entire production batch. Legacy technologies may introduce delays between sampling and results, provide inaccurate readings due to cross-interference, or require frequent calibration—none of which are acceptable in critical UHP gas environments.

1. Molecular Selectivity with No Cross-Interference

TDLAS targets specific absorption lines of gas molecules in the near-IR region. Each gas has a unique spectral “fingerprint.” This means ESEGAS’s TDLAS product can distinguish between gases with extremely high precision—virtually eliminating false positives caused by overlapping signals, a common issue in NDIR and electrochemical methods.

2. Sub-ppb Detection Capability

Using highly stable laser sources and long optical path designs, TDLAS systems can detect trace gases at levels below 1 ppb. This is critical for monitoring impurities like H₂O, HCl, HF, and NH₃ in UHP nitrogen, hydrogen, or argon used in semiconductor and display manufacturing.

3. Real-Time Continuous Monitoring

Unlike GC systems that rely on batch sampling and require minutes to complete an analysis cycle, ESEGAS’s TDLAS product offers continuous, instantaneous readings. This enables real-time process control and immediate fault detection, reducing downtime and contamination risk.

4. Non-Contact, Low-Maintenance Operation

TDLAS systems are based on optical measurement—there are no wetted parts or consumables. ESEGAS’s system is built with an all-digital control loop, long-life laser sources, and automatic baseline correction, dramatically reducing maintenance costs and improving long-term reliability.

5. Compact and Flexible Integration

The modular design of ESEGAS’s TDLAS product makes it suitable for both standalone and integrated inline analysis. It can be easily installed in gas cabinets, purification systems, or distribution networks without extensive reconfiguration.

In summary, ESEGAS’s TDLAS Gas Analysis System overcomes the key limitations of traditional impurity detection methods through high-resolution, real-time laser spectroscopy. It delivers the performance, accuracy, and reliability demanded by industries where ultra-high purity isn’t optional—it’s essential.

Which industries benefit most from ESEGAS’s TDLAS product for UHP gas monitoring?

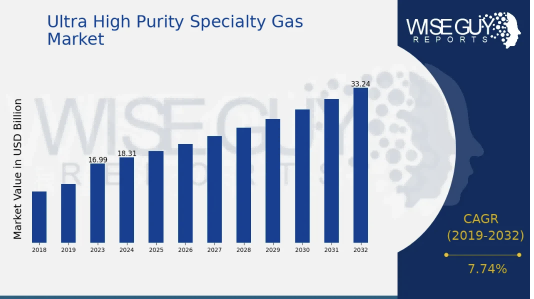

Across high-tech manufacturing sectors, the demand for ultra-high purity (UHP) gases is increasing exponentially. Whether it’s nitrogen in lithography or hydrogen in OLED encapsulation, even minute impurities can compromise product performance, reduce yield, and trigger expensive downtime. Many industries operate with zero tolerance for contamination—where a single molecule of moisture or acid gas can damage layers, alter reactions, or introduce defects.

Traditional gas monitoring systems lack the responsiveness and accuracy to meet these ultra-strict requirements. Manual sampling, batch analysis, or non-specific sensors introduce risk into processes that demand real-time assurance. The inability to detect trace-level H₂O, HCl, or NH₃ in a timely manner could mean millions in losses for just a few minutes of undetected impurity.

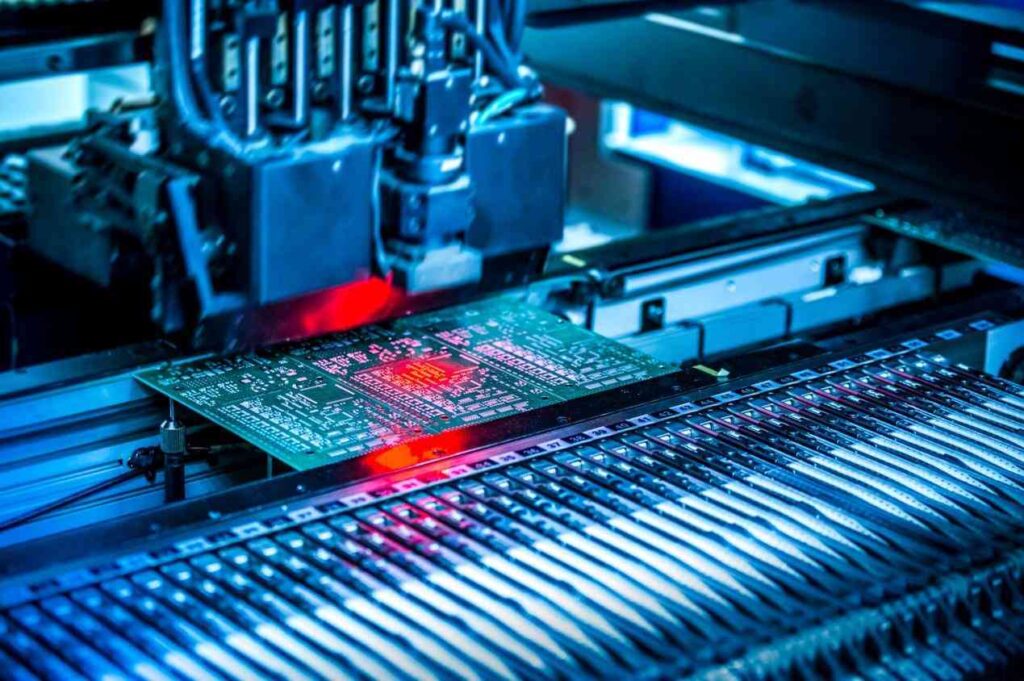

1. Semiconductor Manufacturing

Semiconductor fabrication involves ultra-clean environments and sub-nanometer precision. Process gases like nitrogen, hydrogen, and argon must be free from even ppb levels of contaminants such as water vapor and acid gases.

ESEGAS’s TDLAS product ensures continuous gas purity monitoring during lithography, etching, and deposition, helping fabs improve yield, reduce scrap rates, and comply with ISO 14644 cleanroom standards.

2. Photovoltaic (PV) and Solar Cell Production

In solar manufacturing, impurities during doping or surface treatment stages can degrade cell efficiency. Moisture and ammonia presence in carrier gases can disrupt film formation or cause corrosion.

Using ESEGAS’s TDLAS system, manufacturers can monitor and control gas purity in real time, improving the performance and lifespan of PV modules.

3. OLED and Display Panel Fabrication

OLED devices are extremely sensitive to oxygen and moisture—even trace contamination can shorten operational life or reduce brightness.

ESEGAS’s laser-based analyzer supports inline gas verification in encapsulation chambers, ensuring UHP nitrogen or argon remains uncontaminated throughout production.

4. Specialty Gas Supply Chains

Gas suppliers must deliver certified UHP-grade products to customers in microelectronics, aerospace, and optics. In-cylinder analysis and real-time filling line monitoring are increasingly expected.

With ESEGAS’s TDLAS product, suppliers can implement fast quality checks during gas bottling or transport—minimizing returns, customer claims, and liability risks.

5.CHEMICAL AND PHARMACEUTICAL MANUFACTURING

In high-purity chemical synthesis or sterile pharmaceutical environments, impurity control is essential for product consistency and regulatory compliance.

TDLAS technology provides fast, interference-free gas quality assurance during critical steps such as inerting, drying, or transfer.

In all these industries, ESEGAS’s TDLAS Gas Analysis System stands out for its ability to deliver reliable, ultra-sensitive detection under demanding conditions—ensuring that only gases of uncompromising purity enter the most sensitive processes.

Conclusion

In ultra-high purity gas analysis, ESEGAS’s TDLAS Gas Analysis System stands out by combining unmatched sensitivity, precision, and operational reliability—making it a trusted choice for industries that can’t compromise on gas purity.