Understanding gas behavior in fermentation starts with watching it evolve, and the ESEGAS IR-GAS-600 infrared gas analyzer shines as a precise, real-time window into that transformation. In simple terms, when you mix flour, yeast, and water, yeast digests starch and releases carbon dioxide. By calculating stoichiometry, we estimate roughly 38kg of CO₂ forms from 70kg of fermentable starch. Yet stoichiometric estimates only tell half the story—they serve as a useful guide, not a full picture.

This is where the IR-GAS-600 steps in. It tracks CO₂ continuously, capturing minute-by-minute concentration change—going from the very first bubble of fermentation to near-saturation. The analyzer’s non-dispersive infrared (NDIR) technology keeps readings stable and accurate, even as CO₂ shoots from trace levels toward nearly 100% in closed conditions. Because it spans from parts-per-million to full-scale, operators never lose track, whether during the slow startup or the rapid peak.

Moreover, this tool integrates directly with control systems—so when CO₂ hits a pre-set level, ventilation or process adjustments kick in automatically. In doing so, the IR-GAS-600 turns a static calculation into a living data stream. That shift—from model to real-time insight—opens a new level of process control, safety, and optimization for food-industry fermentations.

Why Does an Infrared Gas Analyzer Matter in Fermentation Process?

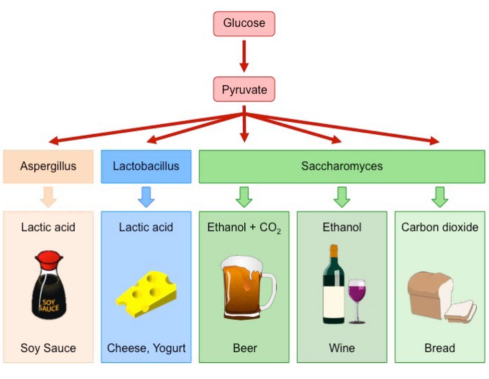

(Production of fermented food)

A. The Fermentation Process in Food Production

When we mix 100 kg of flour with 110 kg of water and add yeast, fermentation begins. Yeast breaks down roughly 70 kg of fermentable starch, converting it into carbon dioxide and ethanol. By applying stoichiometry—where 162g of starch yields 88g of CO₂—we calculate about 38kg of CO₂ emerges from that 70kg starch. Yet the gas evolves as a mix: mostly CO₂, but also water vapor and ethanol. Under typical conditions, the gas composition exceeds 95% CO₂ by volume, so it behaves like nearly pure CO₂ for analysis.

This basic chemistry isn’t just academic—it lays the foundation for monitoring strategies. Understanding how much CO₂ forms (≈38kg) gives us a starting point. But real industrial fermentation isn’t static. That’s where real-time gas analysis enters, turning theory into action.

B. Why Monitoring CO₂ Matters in Food-Industry Fermentation

Monitoring CO₂ delivers value on several critical fronts:

- Safety First: Fermentation in closed tanks can let CO₂ accumulate. High zones of CO₂ can pose asphyxiation risks to workers. Real-time detection allows immediate intervention.

- Process Control: CO₂ output mirrors yeast activity. A sudden slowdown flags metabolic shifts. If you catch it early, you can rethink feeding, aeration, or temperature to steer things back on course.

- Quality & Yield: Continuous tracking of CO₂ evolution helps verify fermentation completeness. You avoid under- or over-fermented batches— improving consistency, reducing waste, and maximizing yield.

Together, these points show how critical monitoring is. And when we bring in an infrared gas analyzer, such as the ESEGAS IR-GAS-600, we elevate our abilities—from static estimates to dynamic, actionable insight. The analyzer doesn’t just measure—it empowers you to manage safety, efficiency, and quality.

How Can an Infrared Gas Analyzer Help Track CO₂ Trends in a Fermentation Tank?

A. Fundamentals of IR-NDIR Technology

Infrared gas analysis relies on the simple principle that certain gases absorb light at specific infrared wavelengths. In an NDIR sensor, infrared light travels through a gas sample. A filter isolates the wavelength that the target gas absorbs. The detector measures how much light gets through. The greater the absorption, the higher the gas concentration—this is the Beer-Lambert law in action

Modern analyzers boost accuracy and stability with a dual-wavelength design. One wavelength acts as a reference; the other targets the gas of interest. This minimizes drift and corrects for light source changes. This setup makes NDIR analyzers robust and well-suited for demanding, continuous industrial use.

B. The ESEGAS IR-GAS-600: Built for Fermentation and Industrial Monitoring

Here’s what the ESEGAS IR-GAS-600 infrared gas analyzer adds to your process:

- Real-time, continuous monitoring: It logs CO₂ by the minute, revealing fermentation phases—lag, peak activity, slowdown. That dynamic insight helps fine-tune conditions or respond rapidly to anomalies.

- High precision across full range: Designed to measure from parts-per-million up to 100% CO₂ with 0.001% resolution and ±2% accuracy, it never saturates—even during peak CO₂ build-up.

- Automation-ready integration: With industry-standard outputs like 4–20 mA and Modbus, the analyzer can trigger ventilation, adjust feed rates, or sound an alarm at set thresholds. This turns raw data into actionable process control.

- Low-maintenance, steady performance: A calibration-free CO₂ channel, auto-purge function, and stable infrared optics reduce downtime and upkeep. Plants benefit from long-term reliability and uninterrupted data flow.

C. Estimating CO₂ Generation in Fermentation

Let’s recap the math clearly. Mixing 100 kg of flour with yeast and water yields about 70 kg of fermentable starch. Through stoichiometry—162g starch → 88g CO₂—you get around 38kg of CO₂. If the fermenter holds 6m³ of gas space at 25°C, that mass of CO₂ translates to roughly 0.035m³ per minute. Therefore, the CO₂ concentration climbs by ~0.587% per minute. In a well-ventilated tank, that path adds about 6,000 ppm per minute. But if the tank seals, CO₂ can accumulate to near 100% in about 160 minutes.

This clear example bridges theory and practice. It shows that while calculations offer a baseline, real-world fermentation includes temperature shifts, yeast lag, and gas dissolution—all factors that benefit from real-time observation.

By shifting from static estimates to continuous feedback, the IR-GAS-600 empowers plant operators to manage fermentation proactively rather than reactively. That raises safety, consistency, and yield—all while simplifying operations.

What Strategic and Philosophical Insights Does an Infrared Gas Analyzer Unlock?

A. From Calculation to Real-World Insight

Our earlier estimate—38kg CO₂ equating to a 0.587% per minute rise in a 6m³ vessel—is a solid starting point. However, it simplifies the process. Real fermentation involves yeast lag phases, temperature shifts, foaming, and CO₂ dissolution. These dynamics create ripples in the gas output that simple stoichiometry can’t reveal.

Thus, the IR-GAS-600 NDIR gas analyzer becomes invaluable. Instead of a static number, it captures a live CO₂ curve, showing you yeast activity and metabolic shifts in real time. You gain process intelligence, not just a number on paper—closing the gap between theory and practice.

B. System Thinking and Empathy

When you watch the CO₂ curve live, your fermenter starts to feel alive. It sends signals—peaks, plateaus, dips. This encourages plant engineers to treat the fermenter like a living system, not an inert vessel.

That mindset shift turns control from reactive guesswork into proactive, data-driven optimization. You don’t just react when something goes wrong; you adjust as trends emerge.

Moreover, the analyzer bridges audiences. General technical readers appreciate the chemical elegance; engineers trust the robust instrumentation. Together, they see how chemical fundamentals connect with real-world tools.

Conclusion

Stoichiometry gives us a solid CO₂ estimate—38 kg from 70 kg of fermentable starch. That frames the theoretical rise in concentration. Yet, it lacks the nuance of live fermentation dynamics. Here, the ESEGAS IR-GAS-600 infrared gas analyzer transforms static numbers into actionable, minute-by-minute insights.

So ask yourself: How might infrared gas analysis reshape your fermentation operations? Could it help prevent CO₂ hazards before they escalate? Could it enable tighter control of feed schedules or temperature shifts to push yield? When CO₂ becomes a signal rather than a by-product, your plant gains a powerful monitoring ally.

FAQs: Infrared Gas Analyzers in Fermentation Processes

Q1: What is the role of CO₂ in fermentation?

Carbon dioxide (CO₂) is a byproduct of fermentation, indicating the metabolic activity of microorganisms. Monitoring CO₂ levels helps assess fermentation progress and detect potential issues.

Q2: How does the ESEGAS IR-GAS-600 measure CO₂?

The ESEGAS IR-GAS-600 employs Non-Dispersive Infrared (NDIR) technology to measure CO₂ concentrations accurately. It offers a wide measurement range from ppm to 100%, with high resolution and minimal maintenance requirements.

Q3: Why is real-time CO₂ monitoring important in fermentation?

Real-time CO₂ monitoring allows for immediate adjustments to the fermentation process, ensuring optimal conditions and preventing issues such as over pressurization or incomplete fermentation.

Q4: Can the ESEGAS IR-GAS-600 be integrated into existing fermentation systems?

Yes, the ESEGAS IR-GAS-600 is designed for easy integration into existing fermentation systems. It supports standard outputs like 4–20 mA and Modbus, facilitating seamless connection with SCADA/PLC systems.

Q5: What are the maintenance requirements for the ESEGAS IR-GAS-600?

The NDIR gas analyzer IR-GAS-600 features a calibration-free CO₂ channel and an auto-purge function, reducing the need for frequent maintenance and ensuring long-term stability.

Q6: How does CO₂ monitoring improve fermentation efficiency?

By providing accurate and timely data on CO₂ production, operators can optimize fermentation parameters, leading to improved yield, consistency, and quality of the final product.

Q7: Is the ESEGAS IR-GAS-600 suitable for large-scale industrial fermentation?

Yes, the NDIR gas analyzer IR-GAS-600 is designed for industrial environments. Its explosion-proof enclosure and robust design make it suitable for large-scale fermentation processes.

Q8: What other gases can the ESEGAS IR-GAS-600 detect?

In addition to CO₂, the NDIR gas analyzer IR-GAS-600 can measure gases like CO, CH₄, and optionally H₂ and O₂, providing comprehensive gas analysis for fermentation processes.

Q9: How does the ESEGAS IR-GAS-600 contribute to safety in fermentation?

By continuously monitoring CO₂ levels, the NDIR gas analyzer IR-GAS-600 helps prevent hazardous gas buildup, ensuring a safe fermentation environment.