ESEGAS has developed a bespoke online CO₂ gas analysis system to monitor bread fermentation in real time. The system tracks CO₂ concentrations from 0 % to 100 %, giving bakers precise control over the fermentation process.

The setup includes a CO₂ analyzer (model IR-GAS-600), a Siemens display panel, a specialized gas-filtration train, interfaces, and a custom enclosure.

Features:

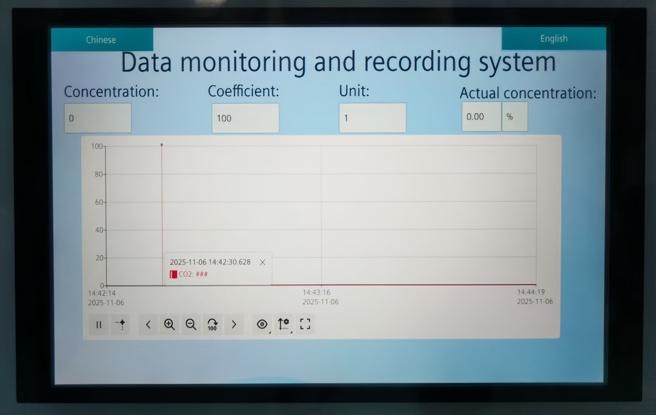

First, the Siemens display shows concentration data live, stores historical data, and offers a USB port for easy export.

Second, the filtration system features a condenser, filters, and gas-drying components, so the analyzed gas remains clean and dry.

Why it matters: CO₂ is the key byproduct of yeast fermentation—and its accumulation reveals how actively dough ferments. Continuous measurement helps bakers judge the fermentation stage, avoid over- or under-proofing, and thus protect loaf texture and flavor. Compared with intermittent manual sampling, this online system gives real-time insight and tighter process control.

Moreover, the data-logging and USB export make the system useful for documentation, recipe standardization, and quality control. For more detailed specs and usage guides, please check our blog or contact us.