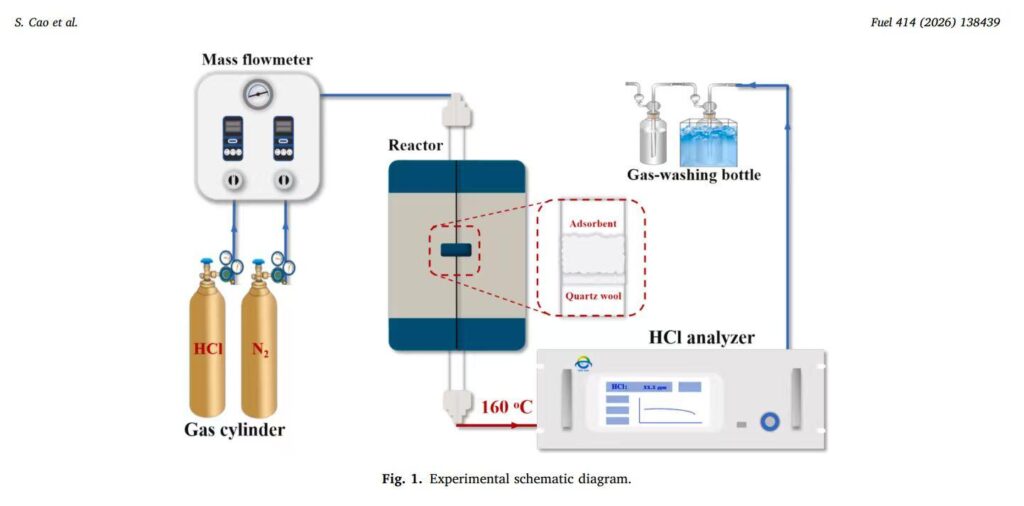

A recent study by Songshan Cao et al., published in Fuel on ScienceDirect (Elsevier). It delivers new mechanistic insights into HCl removal by calcium- and zinc-modified hydrotalcites, integrating experimental data with density functional theory to inform sorbent design for high-temperature flue gas cleaning in thermochemical plants—critical in waste-to-energy, biomass, and coal combustion applications.

To support real-time evaluation of hydrochloric acid in these high-complexity gas streams, the researchers incorporated the ESEGAS ESE-LASER-200 TDLAS Online HCl gas analyzer. Tunable Diode Laser Absorption Spectroscopy (TDLAS) enables continuous, highly selective HCl measurement, delivering fast response and robust performance even amid corrosive, particulate-laden flue gases typical of incineration and combustion environments.

In practical industrial settings, such online HCl monitoring is essential for emission control and process optimization: it helps operators adjust combustion and scrubbing systems in real time, identify transient spikes, and maintain compliance with stringent environmental standards. Continuous monitoring with TDLAS-based gas analyzers like the ESE-LASER-200 provides reliable data that bridges laboratory research and field-scale emission management, offering valuable guidance for engineers focused on reducing equipment corrosion, improving sorbent function, and enhancing overall flue gas treatment strategies.

Explore more at esegas.com or reach out via email at [email protected] to learn how precision gas analysis can elevate your process and emissions research.