(Medical Sterilization Plants)

In industrial processes—from boiler combustion to gas purification—accurate oxygen measurement is not just beneficial: it is essential. Operators rely on real-time O₂ readings to optimize fuel efficiency, control emissions, and ensure safe operation. But when your target concentration is very low (say, 0–5 % vol), the margin for error shrinks dramatically. Noise, drift, non-linearity, and signal interference all become major obstacles.

Many engineers assume that any zirconia oxygen (O₂) analyzer “should work,” but in practice poor choices lead to chronic calibration headaches, unreliable data, or instrument failure. A sensor that performs well at 21 % O₂ may struggle or even misbehave in the 0–5 % window. Similarly, an output signal not suited to your control loop—even if it meets a data sheet spec—can degrade accuracy in situ. Among all the specifications, three often overlooked “non-negotiable” stand out: operating temperature, measuring range, and output signal. If you don’t get these foundational specs right, the rest of the instrument—no matter how feature-rich—might never deliver reliably.

Why Operating Temperature Matters in Zirconia Oxygen Analyzers?

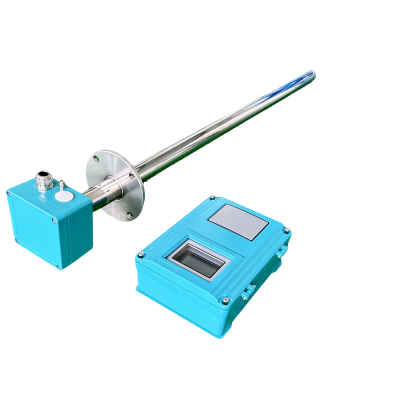

(ESEGAS zirconia oxygen analyzer)

1. What Does “Operating Temperature” Mean?

When we talk about the operating temperature of a zirconia oxygen analyzer, we’re referring to the temperature at which the sensor’s zirconium dioxide (ZrO₂) electrolyte becomes ionically conductive. This typically occurs at temperatures above 450°C. Below this threshold, the sensor cannot function effectively, leading to inaccurate readings and potential sensor damage.

It’s essential to distinguish between:

- Ambient Temperature: The temperature of the surrounding environment where the analyzer is installed.

- Gas Sample Temperature: The temperature of the gas being measured.

- Sensor/Probe Temperature: The temperature at the sensor’s location, which may be influenced by the gas sample and ambient conditions.

Proper thermal coupling and protection are crucial to ensure the sensor reaches and maintains its required operating temperature.

2. Consequences of Temperature Mismatch or Out-of-Range Operation

Operating outside the recommended temperature range can lead to several issues:

- Degraded Sensor Performance: At temperatures below 450°C, the sensor’s ionic conductivity is insufficient, leading to poor accuracy and reliability.

- Thermal Shock: Sudden temperature changes can cause mechanical stress, potentially cracking the ceramic sensor.

- Condensation: Inadequate heating can lead to moisture accumulation, which may corrode the sensor and other components.

- Electronics Instability: Components like heaters and signal processors may experience increased wear, noise, or failure if exposed to temperatures beyond their design limits.

These factors can significantly reduce the analyzer’s lifespan and performance.

3. Practical Challenges in Industrial Environments

Plants impose messy thermal realities. Some typical constraints and countermeasures:

- Ambient heat islands / enclosures: In many industrial yards, ambient temperature may exceed 40 °C occasionally. The analyzer housing may trap heat. Use ventilation, heat sinks, or shading to avoid self-heating.

- Sample line heating & insulation: If the gas path is exposed, it may cool below dew point or fluctuate. Insulate the sample line, or apply trace heating to avoid condensation or temperature gradients.

- Gas pre-conditioning: Filters, moisture traps, or dryers upstream help avoid droplets reaching the sensor during temperature swings.

- Safety / explosion zones: If your analyzer must operate in hazardous areas, the design may require purge, cooling, or separation zones—these add thermal complexity.

- Thermal lag & stabilization time: After startup or ambient shifts, allow warm-up and stabilization time before trusting readings.

Accounting for these constraints in mechanical layout, thermal insulation and cooling strategy is a must.

4. Engineering Guidelines and Best Practices

To ensure reliability over time:

- Specify extra margin beyond worst-case ambient: If you expect up to 40 °C ambient, choose a converter rated to 50–60 °C or more.

- Active thermal control: Use internal heaters, thermostats, or Peltier elements where needed to hold critical zones at setpoint.

- Gradual transitions: Avoid abrupt temperature changes during startup/shutdown; ramp heaters gradually to reduce thermal stress.

- Monitoring & diagnostics: Let the instrument report internal temperatures or fault when thermal drift is too large.

Using such margins makes your analyzer robust in the field and guards against degradation under real plant conditions.

Why Measuring Range Matters in Zirconia Oxygen Analyzers?

(ESEGAS zirconia oxygen analyzer)

1. Range vs. Sensitivity vs. Linearity Trade-Off

At low oxygen concentrations, the voltage output from the zirconia sensor is minimal. This small signal is susceptible to noise and may lack the precision needed for accurate measurements. If an analyzer is designed for a wide range (e.g., 0–25% O₂), its low-end performance can degrade, leading to reduced sensitivity and potential inaccuracies in the 0–5% range

2. Resolution, Repeatability, Zero/Span Drift Implications

In low concentration measurements, even a small error at full scale can translate into significant inaccuracies at lower concentrations. For instance, a 1% error at 100% O₂ is negligible, but at 5%, it’s a 20% error. Zero drift becomes critical when the full scale is small, as any shift can lead to substantial measurement errors. Therefore, calibration strategies involving both span and zero gases are essential to maintain accuracy

3. Range Flexibility, Auto-Scaling, or Multiple Ranges

While flexibility in measuring range can be advantageous, it’s crucial to consider the application’s specific needs. For your requirement of 0–5% O₂, selecting an analyzer with a robust lower range is more beneficial than one with a broader upper range. Features like auto-range or logarithmic scaling can be useful, but they should not compromise the accuracy and stability at the lower end

4. Matching Your Application Constraints

In your case, the 0–5% O₂ range is the “measuring window.” Opting for an analyzer with a lower range ensures higher accuracy and stability within this window. It’s essential to choose an analyzer whose lower end is robust, as exceeding the 5% threshold may not be necessary and could introduce unnecessary complexity and potential for error.

Why Output Signal Matters?

(ESEGAS zirconia oxygen analyzer)

1. Signal Standard in Industrial Control

Analog current loops, particularly 0–20 mA, remain prevalent in industrial control systems due to their simplicity and reliability. These loops are less susceptible to voltage drops and electromagnetic interference, ensuring stable signal transmission over long distances. The 0–20 mA output is commonly used in zirconia oxygen analyzers, such as the ESEGAS Zirconia Oxygen Analyzer ESE-Z-100, to provide a linear representation of oxygen concentration, facilitating integration with various control systems.

2. Zero-Based vs Live-Zero (0–20 mA vs 4–20 mA) Tradeoffs

The choice between 0–20 mA and 4–20 mA output signals impacts system diagnostics and fault detection. A 0–20 mA output allows for a direct representation of zero oxygen concentration, which can be advantageous in applications where detecting very low oxygen levels is critical. However, it may complicate fault detection, as a zero current could indicate either zero oxygen or a system fault. In contrast, a 4–20 mA output maintains a minimum signal of 4 mA, simplifying fault detection but potentially masking very low oxygen levels.

3. Load, Impedance, and Wiring Considerations

When implementing a 0–20 mA output, it’s essential to consider the loop’s load resistance and the power supply’s capability to ensure accurate signal transmission. Excessive load resistance can lead to voltage drops, affecting signal integrity. Proper shielding and grounding of wiring are also crucial to minimize electromagnetic interference, which can distort the signal and impact the analyzer’s performance.

4. Digital Outputs (Optional) and Hybrid Architectures

Incorporating digital communication protocols, such as HART, RS-485, or Modbus, alongside the analog 0–20 mA output can enhance the analyzer’s functionality. These digital interfaces allow for remote monitoring, diagnostics, and configuration, providing real-time data and facilitating predictive maintenance. For instance, the ESEGAS ESE-Z-100 supports both analog and digital outputs, enabling seamless integration into modern industrial control systems.

Selecting the appropriate output signal for a zirconia oxygen analyzer involves balancing the need for accurate oxygen concentration measurement with considerations for system integration, fault detection, and signal integrity. Understanding these factors ensures optimal performance and reliability in various industrial applications.

How Does the ESEGAS ESE-Z-100 Zirconia Oxygen Analyzer Fit Your 0–5% O₂ Monitoring Needs?

1. Overview of the ESEGAS ESE-Z-100 Specifications

The ESEGAS ESE-Z-100 is engineered for precision and durability in demanding industrial environments. Key features include:

- Measurement Range: 0–20.9% O₂

- Output Signal: 0–20 mA

- Response Time: 1–3 seconds

- Operating Temperature: Up to 1700°C

- Mounting: Flanged installation suitable for closed systems

- Calibration: Auto-calibration with built-in diagnostics

These specifications make the ESE-Z-100 a robust choice for continuous O₂ monitoring in industrial processes.

2. Alignment with Your 0–5% O₂ Monitoring Requirements

Your specified requirements are:

- Measurement Range: 0–5% O₂

- Output Signal: 0–20 mA

- Operating Temperature: 0–40°C

- Installation: Closed system with flanged connection

The ESE-Z-100’s 0–20.9% O₂ range exceeds your 0–5% requirement, providing headroom for potential process variations. Its 0–20 mA output signal aligns with your specifications, ensuring compatibility with existing control systems. The analyzer’s high-temperature tolerance up to 1700°C is more than sufficient for your ambient operating conditions of 0–40°C. Its flanged installation capability suits your closed system setup.

3. Customization and Supplier Engagement

To optimize the ESE-Z-100 for your specific application, consider the following:

- Firmware Configuration: Request adjustment of the measurement range to 0–5% O₂ to enhance accuracy within your operating window.

- Calibration Procedures: Ensure calibration is performed at the lower end of the range to maintain precision.

- Performance Data: Obtain factory test results for the 0–5% O₂ range to verify stability and accuracy.

- Environmental Considerations: Discuss potential derating under field conditions, accounting for factors like humidity and vibration.

Engaging with the supplier on these aspects will help tailor the ESE-Z-100 to your operational needs.

4. Scenario Simulation and Risk Assessment

Consider potential challenges such as:

- Ambient Temperature Fluctuations: Evaluate the impact of temperature variations on sensor performance and calibration.

- Signal Integrity: Assess the effects of cable length and potential noise on the 0–20 mA output signal.

- Sensor Drift: Monitor zero and span drift over time to maintain measurement accuracy.

- Maintenance Intervals: Determine optimal calibration and maintenance schedules to ensure consistent performance.

By simulating these scenarios, you can anticipate potential issues and implement proactive measures to mitigate risks.

The ESEGAS ESE-Z-100 zirconia oxygen analyzer offers robust features that align well with your 0–5% O₂ monitoring requirements. With appropriate customization and careful consideration of operational factors, it can serve as a reliable component in your industrial processes.

Conclusion

The ESEGAS ESE-Z-100 Zirconia Oxygen Analyzer offers a range of features that can align with your application needs. Through careful customization and consideration of potential challenges, you can leverage this analyzer to achieve accurate and reliable oxygen measurements in your specific environment.

If you want to know more, contact with us please!

Frequently Asked Questions (FAQ)

Q1. What is the significance of the operating temperature in a zirconia O₂ analyzer?

A1. The operating temperature is critical because zirconia sensors must be heated (typically 600–900 °C or more) to become ionically conductive.

- If the sensor or electronics operate outside their designed ambient/gas temperature range (e.g. too cold), ionic conduction becomes weak, signal weakens, sensor drift increases, and accuracy degrades.

- Conversely, overexposure to temperature extremes (or thermal shock) can damage sensor ceramics or reduce lifespan.

- In your application (ambient up to 40 °C), the analyzer’s electronics must tolerate that ambient range with margin, while the internal sensor heater must reliably maintain the required high temperature.

Thus, selecting a model whose ambient and internal thermal tolerances exceed your worst real conditions is essential for stable, long-term performance.

Q2. Why is the measuring range so important in selecting a zirconia oxygen analyzer?

A2. The measuring range determines how well the zirconia oxygen analyzer can resolve small changes in oxygen concentration at your target region. Some points to understand:

- A wide-range analyzer (say 0–25 %) may have lower resolution, higher noise, or degraded accuracy at the low end (0–5 %) because the sensitivity is spread over a larger span.

- Lower full scale means smaller cell voltages at low O₂, so zero drift and signal noise become more critical.

- If your process always stays within 0–5 %, it’s better to pick a device specifically rated for that narrow band (or able to reliably linearize there) rather than overbuying range with compromise at the low end.

- Some analyzers offer selectable or multi-range modes; these provide flexibility but require careful calibration and verification.

So the measuring range is not a “bonus spec” — it’s a performance boundary you must match to your process demands.

Q3. Why choose an output signal of 0–20 mA (rather than voltage or digital) for a zirconia Oxygen analyzer?

A3. The choice of output signal impacts integration, control, diagnostics, and signal integrity. Key reasons to specify 0–20 mA:

- Robustness & distance: Current loops (mA) are less sensitive to voltage drop, cable resistance, and electrical noise over long wiring runs.

- Zero baseline: 0–20 mA (versus 4–20 mA) allows true zero reading; useful in low ranges near zero O₂.

- Interoperability: Many DCS/PLC systems accept analog current inputs as a standard.

- Diagnostics: Some analyzers allow “fail-safe” signal behavior (e.g. outputting < 0 mA or > 20 mA on fault) or switch to alternate modes.

- Re-transmission flexibility: Many analyzers allow you to program retransmission scaling (e.g. 0–20 mA across your selected %O₂ range).

However, you should also consider whether a zirconia oxygen analyzer supports digital protocols (HART, Modbus) in parallel to analog, as that gives you extra diagnostic and monitoring capabilities without losing compatibility.

Q4. How are these three parameters (temperature, measuring range, output signal) interrelated?

A4. They are not independent; tradeoffs and dependencies exist:

- A narrow measuring range (low full scale) requires high signal stability and low drift, which in turn demands excellent thermal control of the sensor (tight temperature regulation).

- Ambient temperature variation influences baseline zero drift, affecting low-end measurement accuracy.

- A weak signal (from low O₂) must be translated cleanly into your output (e.g. 0–20 mA) — so signal amplification, filtering, and output electronics must be precise under varying temperature stress.

- If you overdesign one spec (say output reach), but ignore temperature margins or range resolution, performance may still fail in real use.

Thus, you cannot treat them separately — the “whole system” must be coherent and robust across all three axes.

Q5. What questions should I ask a supplier when ordering for 0–5 % zirconia Oxygen analyzers?

A5. To ensure the zirconia oxygen analyzer meets your application, here are some targeted questions:

- What is the ambient operating temperature range (housing, electronics) and does it include margin above 40 °C?

- What is the stability, drift (zero and span) over time, especially at the low end (0–5 %)?

- Can the device output 0–20 mA, and is that programmable or fixed?

- Does it support digital communication in parallel (e.g. HART, Modbus)?

- Can the manufacturer provide performance data (test curves) specifically for your selected 0–5 % range?

- How is the sensor heater / thermal control implemented, and how does it react to ambient temperature swings?

- What are the response time / lag at low O₂ levels?

By asking these, you force the vendor to think in your context, not generic specs.

Q6. In practice, how do I ensure long-term accuracy and reliability in the field?

A6. Here are some practical strategies for zirconia oxygen analyzer maintenance:

- Routine calibration & zero/span checks at regular intervals.

- Temperature stabilization in enclosures: avoid heating or cooling swings around the electronics.

- Use shielded, low-resistance wiring, and respect the loop current limitations.

- Install filters or moisture traps in the sample line to prevent condensation or particulates damaging the sensor.

- Monitor drift or trend data (if digital) to detect degradation before failure.

- Maintain spare parts (e.g. replacement sensors) and perform preventive maintenance.

- Whenever possible, log ambient conditions alongside O₂ readings — correlation between ambient swings and drift may reveal hidden thermal issues.