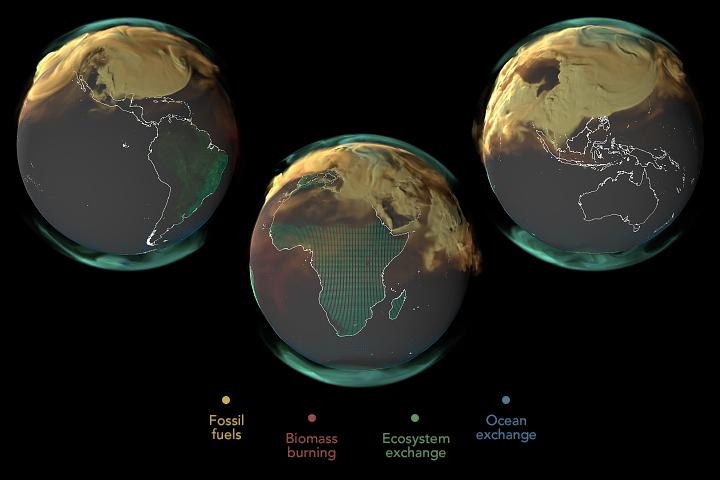

Climate change now ranks among humanity’s most urgent threats. Global surface temperatures have risen 1.1°C since pre-industrial times, with atmospheric CO₂ concentrations exceeding 420 ppm in 2023—a 50% increase since 1750. The IPCC warns that limiting warming to 1.5°C requires 45% emissions reduction by 2030. Since the Industrial Revolution, burning fossil fuels, deforestation, and industrial farming have dramatically increased atmospheric greenhouse gases. To combat this crisis, precise greenhouse gas monitoring systems, including (Non-Dispersive Infrared) NDIR gas analyzers, provide vital data for evaluating emission sources and shaping climate policies.

(Emissions from Fossil Fuels Continue to Rise)

What Exactly Are Greenhouse Gases?

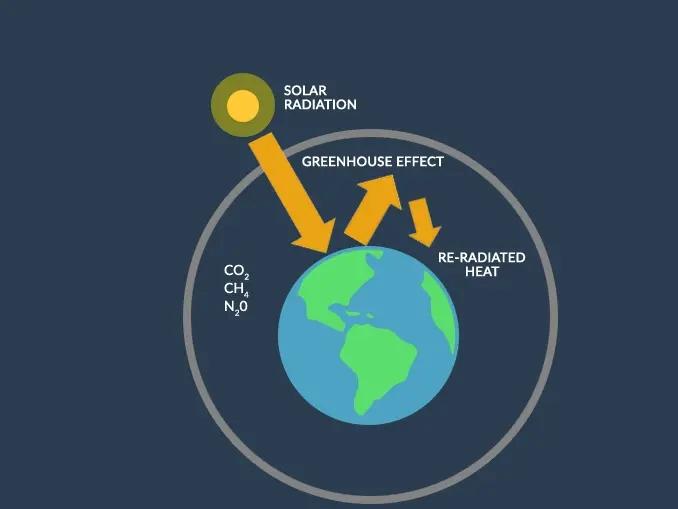

Greenhouse gases (GHGs) are atmospheric compounds that absorb and re-emit infrared radiation, directly influencing global warming. Key culprits include:

– Carbon Dioxide (CO₂): Mainly released from burning fossil fuels, deforestation, and cement production.

– Methane (CH₄): Originates from livestock digestion, rice paddies, fossil fuel extraction, and waste management.

– Nitrous Oxide (N₂O): Emitted during fertilizer use, agricultural soil management, and various industrial processes.

Unlike oxygen or nitrogen, these gases trap heat efficiently, creating a “blanket effect” that elevates planetary temperatures. For climate change solutions, tracking their concentrations is critical for identifying emission hotspots and verifying reduction efforts.

Why Is Precise Greenhouse Gas (GHG) Monitoring Essential?

Increasing concentrations of greenhouse gases can lead to environmental problems such as global warming, sea level rise and climate anomalies. Therefore, GHG monitoring is crucial to combating global climate change, and its necessity is reflected in the following aspects:

a. Continuous GHG tracking provides scientists with dynamic insights into atmospheric changes. The datasets, such as emission trends across regions, clarify how human activities disrupt natural climate cycles and improve predictive models.

b. Governments and organizations need actionable data of Greenhouse Gas (GHG) Monitoring to craft effective emission regulations. Advanced analyzers identify industrial hotspots, quantify sector-specific contributions, and verify compliance with agreements like the Paris Accord. Reliable metrics empower leaders to enforce targeted measures, adjust policies swiftly, and hold stakeholders accountable.

c. Greenhouse Gas (GHG) Monitoring can pinpoint Environmental Vulnerabilities. This precision helps prioritize remediation efforts. For example, a factory emitting excess nitrous oxide could upgrade machinery, while cities might redirect funds to renewable infrastructure. By linking emissions to specific activities, communities adopt tailored solutions rather than generic fixes.

Why Choose NDIR Gas Analyzers for Precision Greenhouse Gas Monitoring?

Accurate greenhouse gas monitoring faces persistent challenges, and understanding these hurdles helps professionals select the right tools. Let’s explore common obstacles and how NDIR technology overcomes them.

—Challenge 1: Environmental Interference

Fluctuations in temperature, humidity, or pressure often distort sensor readings. For instance, a sudden temperature shift might alter gas density, skewing measurements. Traditional sensors struggle to compensate for these variables, risking data reliability.

Solution: Targeted Wavelength Isolation

NDIR gas analyzers tackle this by focusing on specific infrared (IR) wavelengths absorbed by target gases like CO₂ or methane. Optical filters block irrelevant wavelengths, ensuring environmental noise minimally impacts results. This design stabilizes measurements even in fluctuating field conditions.

—Challenge 2: Cross-Sensitivity Errors

Many gas sensors react to multiple gases, creating false signals. A methane detector might mistakenly respond to propane, for example, complicating data interpretation.

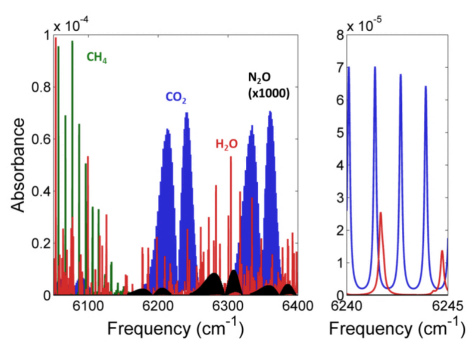

Solution: Spectral Fingerprinting

NDIR analyzers exploit the unique IR absorption “fingerprint” of each gas. By tuning sensors to detect only these signatures, the technology virtually eliminates cross-sensitivity. This specificity proves critical in mixed-gas environments like industrial sites.

—Challenge 3: Calibration Drift

Frequent recalibration drains resources and causes downtime. Electrochemical sensors, for instance, often degrade, requiring weekly adjustments.

Solution: Inherent Stability

NDIR systems use solid-state optics with minimal drift, slashing calibration needs. Some models maintain accuracy for months, cutting maintenance costs by up to 60% compared to traditional tools.

How Do NDIR Gas Analyzers Deliver Precise Greenhouse Gas Measurements? What is NDIR Technology?

(Greenhouse gases wavelengths)

Non-dispersive infrared (NDIR) gas analyzers measure gas concentrations using infrared absorption principles. These devices rely on the fact that specific gases absorb unique wavelengths of infrared light. For example, CO₂ absorbs light at 4.26 µm, while methane absorbs at 3.3 µm.

How Many Key Components Do NDIR Gas Analyzers Have?

NDIR (Non-Dispersive Infrared) gas analyzers rely on four core components to detect gases with high accuracy. Understanding how these parts work together helps users evaluate instrument performance for their specific needs.

- Infrared Source: Stability Defines Reliability

The infrared source emits a consistent wavelength beam, typically using heated ceramics or micro-filaments. Durable materials like tungsten or silicon carbide ensure long-term thermal stability. When selecting an analyzer, consider sources with low drift—this minimizes calibration frequency and maintains measurement consistency in continuous monitoring scenarios.

- Sample Chamber: Design Impacts Sensitivity

Gas enters the sample chamber, where infrared light interacts with target molecules. Engineers optimize path length and internal coatings to enhance signal strength. For example, a 10cm chamber suits high-concentration detection, while mirrored chambers amplify weak signals in low-ppm applications. Always match chamber specifications to your expected gas concentration ranges.

- Optical Filters: Precision Targeting Gas Signatures

Bandpass filters isolate absorption peaks unique to each gas. Advanced analyzers use tunable Fabry-Pérot filters or multi-gas filter wheels. Narrower bandwidths (e.g., 150nm) improve selectivity but require stricter temperature control. Prioritize analyzers with interference-resistant filters if measuring gases with overlapping IR spectra like methane and propane.

- Detectors: Converting Light to Actionable Data

Pyroelectric or photodiode detectors measure attenuated light intensity after gas absorption. Dual-detector configurations compensate for environmental noise, while thermoelectrically cooled detectors boost sensitivity in sub-ppm applications. For field devices, verify the detector’s response time—faster models (<5s) excel in leak detection, whereas slower ones may suffice for ambient air monitoring.

How Do NDIR Gas Analyzers Work? Understanding the Science Behind Accurate Measurements

At its core, non-dispersive infrared (NDIR) gas analyzers rely on a fundamental principle: gases absorb specific wavelengths of infrared light. This interaction forms the basis for measuring gas concentrations with high precision. But how exactly do these devices translate light absorption into actionable data? Let’s explore the science that makes NDIR technology so reliable.

—The Beer-Lambert Law: A Bridge Between Light and Gas Concentration

The Beer-Lambert law mathematically links light absorption to gas properties. Simply put, when infrared light passes through a gas sample, molecules like CO₂ or methane absorb energy at unique wavelengths. The law states that the amount of absorbed light depends on three factors:

—the gas’s absorption strength (molar absorptivity),

—the path length of the light through the gas

—the gas concentration.

The Beer-Lambert law (I = I₀e^(-αcl)), where absorption coefficient (α), gas concentration (c), and optical path length (l) determine light attenuation. For instance, if a gas has strong infrared absorption bands, the analyzer will detect a significant drop in light intensity. Engineers design NDIR sensors with optimized path lengths and wavelength filters to target specific gases. However, users should remember that overlapping absorption spectra or fluctuating environmental conditions (like temperature) can affect accuracy. Always verify whether your analyzer compensates for these variables.

—Key Factors Influencing NDIR Gas Analyzers Performance

While the Beer-Lambert law provides a theoretical foundation, real-world applications demand attention to practical details:

First, ensure the analyzer’s infrared source and detector remain stable over time—drift can skew results.

Second, consider gas pressure and temperature, as these alter molecular density and absorption behavior. Modern NDIR devices often include built-in compensation algorithms for such factors.

Additionally, watch for cross-interference from gases with similar absorption profiles. For example, water vapor can interfere with CO₂ readings in humid environments. Advanced models use spectral filtering or reference cells to minimize this issue. When selecting an analyzer, prioritize models with proven interference resistance for your target application.

What are the Advantages of NDIR Gas Analyzers Comparing with Other Technologies?

To measure greenhouse gases such as CO₂, CH₄, and N₂O, several technologies are employed. Below is a comparison of Non-Dispersive Infrared (NDIR) analyzers with other common methods:

| Technology | Principle | Gas Measured | Advantages | Limitations |

| NDIR (Non-Dispersive Infrared) | Measures gas absorption of specific IR wavelengths. | CO₂, CH₄, N₂O | High accuracy; robust; widely used. | Higher cost; energy consumption. |

| FTIR (Fourier Transform Infrared Spectroscopy) | Captures full IR spectrum to identify gases. | Multiple gases including CO₂, CH₄, N₂O | Simultaneous multi-gas detection; high sensitivity. | Complex data analysis; expensive. |

| Tunable Diode Laser Absorption Spectroscopy (TDLAS) | Uses laser tuned to specific gas absorption lines. | CH₄, N₂O | High specificity; rapid response. | Sensitive to alignment; limited to specific gases. |

| Gas Chromatography (GC) | Separates gases in a mixture for individual analysis. | CO₂, CH₄, N₂O | High precision; suitable for complex mixtures. | Requires sample preparation; longer analysis time. |

| Photoacoustic Spectroscopy (PAS) | Detects sound waves produced by gas absorbing modulated light. | CO₂, CH₄ | High sensitivity; compact design. | Affected by external noise; calibration needed. |

Each technology offers unique benefits and challenges, making them suitable for different applications in greenhouse gas monitoring. ESEGAS is able to provide tailored solutions base on various problems and needs.

What Are the Future Innovations in NDIR Gas Analyzers?

NDIR (Non-Dispersive Infrared) gas analyzers in sensor miniaturization now empower developers to create portable, low-power devices without sacrificing accuracy. Fortunately, emerging technologies promise transformative improvements. Advanced laser-based light sources, such as quantum cascade lasers, minimize spectral interference by targeting narrower absorption bands. MEMS (Micro-Electromechanical Systems) sensors now enhance resistance to environmental noise while reducing power consumption. Furthermore, IoT integration allows these compact sensors to transmit data seamlessly to cloud platforms. This connectivity supports predictive maintenance, reducing downtime in industrial settings by up to 30%.

(The Internet of Things (IoT))

Transitioning to data analytics, machine learning algorithms now decode complex gas patterns that traditional methods miss. For example, neural networks can distinguish methane leaks from background CO2 fluctuations in oil refineries. Pairing these algorithms with edge computing cuts latency, letting operators act on insights within milliseconds. However, users must verify algorithmic transparency to avoid “black box” decision-making.

To stay competitive, prioritize NDIR systems with modular designs for easy IoT upgrades. Assess whether your application demands ultra-portability or lab-grade precision. Finally, partner with vendors offering explainable AI tools to balance automation with human oversight. By aligning these innovations with operational needs, businesses can optimize safety, efficiency, and compliance in gas detection.

If you want to know more, contact with us please!