Unlock the potential of UV gas analyzers for enhanced detection. This blog aims to educate and inform on UV gas analyzer basics, advantages, applications, and techniques to maximize their capabilities.

Basics Of UV Gas Analyzers!

Discover the science behind UV gas analyzers, from the principle of UV absorption spectroscopy to their crucial components.

The Principle of UV Absorption Spectroscopy!

UV gas analyzers employ ultraviolet (UV) absorption spectroscopy to measure gas concentrations. As gases absorb UV light, each exhibits a distinct absorption spectrum.

The analyzer identifies specific gases and measures their concentrations based on light absorption at specific wavelengths. For instance, sulfur dioxide (SO2) strongly absorbs light at 190-230 nm, while nitrogen dioxide (NO2) absorbs at 350-450 nm.

The high selectivity of UV absorption spectroscopy ensures accurate, real-time measurements for various applications, including emissions monitoring and process control.

Components of A UV Gas Analyzer!

Explore the vital components of a UV gas analyzer, including the light source, sample cell, detector, and signal processing.

Light Source

UV gas analyzers use a light source, like a deuterium lamp, emitting a broad spectrum of UV light. Deuterium lamps generate wavelengths from 160 to 400 nm, providing the wide range necessary for accurate gas detection. The lamp’s lifespan depends on usage, typically lasting 1,000 to 2,000 hours.

Sample Cell

The sample cell, a critical component, houses the gas sample. Its design ensures efficient interaction between the UV light and gas sample. To minimize interference and maintain accuracy, the sample cell often features anti-reflective coatings, precisely controlled path lengths, and temperature control systems.

Detector

Upon passing through the sample cell, the UV light reaches the detector. UV detectors, such as photodiode arrays or charge-coupled devices, convert light intensity variations into electrical signals. The detector’s sensitivity and stability are crucial for accurate gas measurements.

Signal Processing and Display

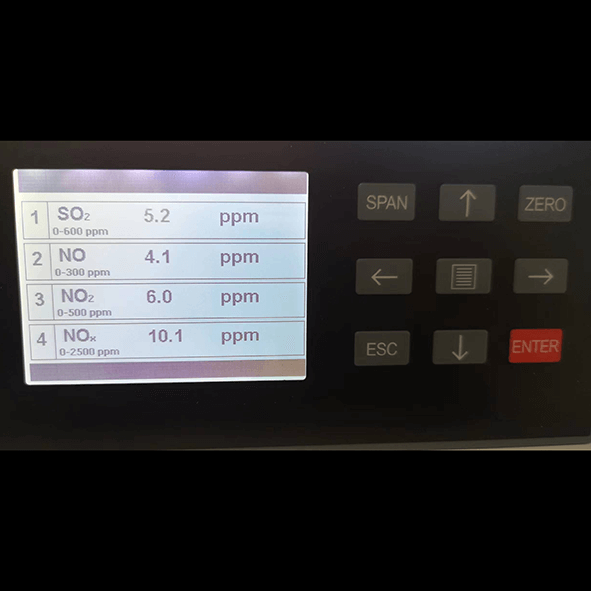

The signal processing unit interprets the detector’s electrical signals and calculates gas concentrations using algorithms. Modern UV gas analyzers feature advanced displays, offering user-friendly interfaces, data storage, and communication capabilities for seamless integration into monitoring systems.

Types Of UV Gas Analyzers!

UV gas analyzers come in two main types: single-beam and dual-beam analyzers, each with unique capabilities.

§ Single-Beam Analyzers

Single-beam UV gas analyzers measure gas concentrations using a single light path. Although cost-effective, they are susceptible to errors from light source fluctuations or environmental factors. To maintain accuracy, regular calibration and maintenance are essential.

§ Dual-Beam Analyzers

Dual-beam UV gas analyzers use two light paths: one for the sample gas and another for reference. By comparing the two signals, these analyzers minimize errors from light source fluctuations, increasing accuracy and stability. Although more expensive, dual-beam analyzers offer higher precision but require less frequent calibration.

What Kinds of Gases Can Be Measured By UV Gas Analyzer?

UV Gas Analyzer measures multiple gases. Here’s a deep dive into some of them:

- Sulfur Dioxide (SO2): UV Gas Analyzers detect sulfur dioxide with high accuracy. In power plants, SO2 emissions can reach 1,500 mg/Nm³. Accurate SO2 detection aids in maintaining emission standards.

- Nitrogen Oxides (NOx): Emitted from vehicles and industries, NOx gases are harmful pollutants. With UV Gas Analyzers, you can measure NOx levels up to 1,000 ppm. Monitoring helps in pollution control.

- Ozone (O3): Present in the Earth’s upper atmosphere, ozone shields us from harmful UV radiation. UV Gas Analyzers detect O3 concentration levels ranging from 0-10 ppm, crucial for environmental monitoring.

- Ammonia (NH3): Used in fertilizers, NH3 can cause environmental issues. UV Gas Analyzers measure NH3 levels up to 1,000 ppm, helping in safe handling.

- Hydrogen Sulfide (H2S): Emitted from wastewater treatment plants, H2S is a toxic gas. UV Gas Analyzers detect H2S concentrations up to 500 ppm, ensuring occupational safety.

Comparison Table On Different Types Of Gases

| Gas Type | Source/Use | Maximum Measurable Concentration | Importance of Measurement |

| Sulfur Dioxide (SO2) | Power Plants | 1,500 mg/Nm³ | Emission Standard Maintenance |

| Nitrogen Oxides (NOx) | Vehicles, Industries | 1,000 ppm | Pollution Control |

| Ozone (O3) | Earth’s Upper Atmosphere | 0-10 ppm | Environmental Monitoring |

| Ammonia (NH3) | Fertilizers | 1,000 ppm | Safe Handling, Environmental Issues |

| Hydrogen Sulfide (H2S) | Wastewater Treatment Plants | 500 ppm | Occupational Safety |

Advantages Of UV Gas Analyzers!

UV gas analyzers offer superior performance in various applications. Key advantages include high sensitivity, rapid response time, and long-term reliability.

o High Sensitivity And Selectivity

UV gas analyzers excel in sensitivity and selectivity. The technique achieves detection limits as low as parts per billion (ppb) levels. Advanced spectrometers ensure precise wavelength selection, allowing for accurate measurements of targeted gas species without interference from others.

o Rapid Response Time

UV gas analyzers provide real-time monitoring with response times as fast as milliseconds. Quick detection allows for immediate corrective actions, preventing hazardous situations and optimizing process efficiency in industries like petrochemical and power generation.

o Long-Term Stability And Reliability

With minimal drift and calibration requirements, UV gas analyzers maintain accuracy over extended periods. High-quality components and robust design ensure reliable performance, making them ideal for continuous emissions monitoring systems (CEMS) and critical industrial processes.

o Minimal Maintenance

UV gas analyzers require minimal maintenance, thanks to non-contact optical sensing techniques. The absence of consumables, such as chemical reagents or filters, reduces operating costs and minimizes downtime for maintenance activities.

o Non-Destructive Analysis Technique

UV gas analysis is non-destructive, preserving sample integrity. This feature makes it ideal for applications in research, quality control, and emissions monitoring, where preserving samples for further analysis or regulatory compliance is essential.

o Multiple Gases Measurement

UV gas analyzers can simultaneously measure multiple gas species, streamlining monitoring processes. This capability is invaluable for industries like automotive emissions testing and air quality management, where detecting a wide range of pollutants is crucial.

o No Requirement For Sample Preparation

UV gas analyzers eliminate the need for time-consuming sample preparation. Direct in-situ measurements provide accurate, real-time results without the complications of extracting, conditioning or transporting samples. This advantage increases efficiency and reduces potential errors in analysis.

Applications Of UV Gas Analyzers In Various Industries!

UV gas analyzers play a vital role in diverse industries, ensuring precise measurements and compliance with regulations. Let’s explore their applications in different sectors.

✔ Monitoring Emissions In Power Plants

UV gas analyzers help reduce harmful emissions in power plants by continuously monitoring flue gas constituents like SO2 and NOx. Accurate data enables plant operators to optimize combustion processes, adhere to strict environmental guidelines, and improve overall efficiency.

✔ Indoor And Outdoor Air Quality Control

UV gas analyzers provide essential data for maintaining healthy indoor and outdoor air quality. By detecting harmful pollutants, such as ozone and nitrogen dioxide, you can implement effective control measures, safeguard public health, and meet air quality standards.

✔ Process Control In Chemical And Petrochemical Industries

In chemical and petrochemical industries, UV gas analyzers ensure efficient process control by monitoring critical gas concentrations. Timely detection of deviations enables prompt corrective actions, resulting in improved product quality, reduced waste, and enhanced operational safety.

✔ Leak Detection In Natural Gas Pipelines

UV gas analyzers contribute to the safety and reliability of natural gas pipelines by detecting leaks. Early detection of methane emissions prevents potential hazards, minimizes environmental impacts, and reduces financial losses due to wasted resources.

✔ Environmental Compliance In Waste Treatment Facilities

UV gas analyzers monitor waste treatment facilities to ensure compliance with environmental regulations. By accurately measuring emissions like ammonia and hydrogen sulfide, facilities can optimize treatment processes, prevent environmental damage, and avoid regulatory penalties.

✔ Ensuring Safety In Mining Operations

In mining operations, UV gas analyzers monitor air quality for hazardous gases, such as carbon monoxide and sulfur dioxide. Real-time data helps maintain worker safety, prevent health issues, and mitigate the risk of accidents in this high-risk industry.

✔ Monitoring Fermentation Process In Breweries

UV gas analyzers play a crucial role in breweries by monitoring the fermentation process. Analyzing gases like carbon dioxide and oxygen helps maintain optimal conditions, resulting in consistent product quality, enhanced flavor profiles, and increased production efficiency.

How To Enhance the Detection Capabilities of UV Gas Analyzers?

To optimize the performance of UV gas analyzers, focus on improving critical components and maintenance practices. Enhance the light source quality, increase detector sensitivity, optimize sample cell design, employ advanced signal processing algorithms, regularly calibrate the instrument, and utilize narrow bandpass filters.

ü Improving the Quality of the Light Source

For precise UV gas analysis, a superior light source is essential. opt for a deuterium lamp with increased output, about 30 mW/nm, covering a wide 190-400 nm spectral range.

Ensure the lamp has an extended lifespan, around 2,000 hours. Align the optical system effectively to reduce light loss and achieve peak sensitivity. Inspect the lamp routinely and replace it when necessary, sustaining top performance and preventing expensive downtime.

ü Increasing the Sensitivity Of The Detector

A highly sensitive detector boosts UV gas analyzer capabilities. Employ a photomultiplier tube (PMT) with high quantum efficiency, above 40% in the UV region.

The PMT should have a fast response time, less than 10 ns, and a low dark current, around 1 nA. Cooling the detector to -40°C significantly reduces noise and increases the signal-to-noise ratio. Shield the detector from stray light to prevent false readings.

ü Optimizing The Sample Cell Design

An optimal sample cell design is crucial for efficient UV gas analysis. The cell should have high transmission and low absorption material, such as quartz or fused silica. Incorporate a multipass configuration to increase the effective path length, enhancing detection sensitivity.

Ensure the cell has minimal dead volume, reducing sample carryover and shortening response times. Maintain a clean sample cell to prevent contamination and inaccurate measurements.

ü Employing Advanced Signal Processing Algorithms

Advanced signal processing algorithms enhance the accuracy of UV gas analyzers. Implement differential optical absorption spectroscopy (DOAS) to isolate target gas absorptions from interfering species.

Employ Fourier-transform techniques for noise reduction and spectral resolution improvement. Utilize chemometric algorithms, like principal component analysis, for multicomponent analysis and interference correction. These techniques maximize the analyzer’s sensitivity and specificity.

ü Regularly Calibrating the Instrument

Regular calibration ensures the UV gas analyzer maintains accuracy and reliability. Perform zero and span calibrations using certified calibration gases with known concentrations. Conduct calibrations at least once every three months or more frequently for demanding applications.

Maintain a detailed calibration log, including dates, results, and adjustments made. Strict adherence to calibration schedules prevents drift and maintains optimal performance.

ü Utilizing Narrow Bandpass Filters

Narrow bandpass filters improve the specificity of UV gas analyzers. Select filters with high transmittance, greater than 90%, and narrow spectral bandwidth, around 0.5-1 nm. Filters should have a steep spectral slope, less than 0.2 nm, for excellent out-of-band rejection.

Incorporate temperature-stabilized filters to maintain consistent performance under varying conditions. Properly align and maintain filters to achieve optimal detection capabilities

Top 10 UV Gas Analyzer Suppliers In The World!

- ABB: A global technology leader, ABB provides advanced UV Gas Analyzers. Their products offer high precision and reliability, catering to various industries.

- Thermo Fisher Scientific: Known for cutting-edge scientific research tools, Thermo Fisher’s UV Gas Analyzers are top-notch. They support environmental and industrial emission monitoring.

- Siemens: Siemens offers UV Gas Analyzers for a range of gases. Their products integrate seamlessly into process control systems, aiding in emission management.

- ESEGas: ESEGas is known for its advanced UV Gas Analyzers, which provide accurate measurements. These analyzers are perfect for environmental monitoring, helping industries meet emission standards.

- Emerson: Emerson’s UV Gas Analyzers are robust and versatile. Ideal for continuous gas monitoring, they serve several sectors including oil and gas.

- Horiba: Horiba’s UV Gas Analyzers deliver high selectivity and sensitivity. They help industries meet stringent emission regulations.

- Fuji Electric: Fuji Electric’s UV Gas Analyzers offer accurate readings. Their products are perfect for process control and environmental monitoring.

- AMETEK Process Instruments: AMETEK offers reliable UV Gas Analyzers. Their products provide real-time data, enhancing operational efficiency.

- Spectrasensors: Specializing in gas analysis, Spectrasensors offers advanced UV Gas Analyzers. Their products ensure safety and optimize process control.

- Testo: Testo’s UV Gas Analyzers provide precise measurement results. Ideal for industrial emission monitoring, they aid in meeting environmental standards.

Conclusion

In summary, selecting the ideal UV gas analyzer requires thorough research and an understanding of your specific needs. Prioritize proven manufacturers with expertise, innovation, and excellent customer service. For optimal performance, trust ESEGas, a reputable provider dedicated to offering high-quality gas analyzers, tailored solutions, and exceptional support to ensure your operations run smoothly and efficiently. Don’t settle for less; choose ESEGas.com for the most reliable gas analysis experience.