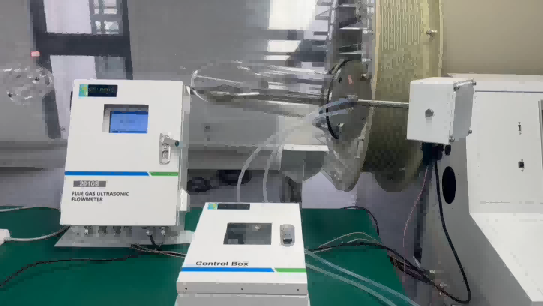

Meet the LEUF-200: a next-generation ultrasonic flow meter that offers precise gas flow measurement. It also supports optional temperature and pressure sensing—ideal for demanding industrial environments.

Why the Ultrasonic Flow Meter Stands Out?

1. Accurate Three-in-One Sensing

The LEUF-200 uses advanced ultrasonic technology to measure flow velocity, temperature, and pressure simultaneously. As a result, it provides accurate standardized flow rates. You no longer need separate instruments—this all-in-one solution simplifies setup and cuts costs.

2. Simple Installation for Any Site

It can be used in closed lines as well as in open gas streams. Its modular design includes two ultrasonic sensors and a central controller. With built-in analog and digital interfaces, the system adapts to varied communication protocols. Additionally, you can expand external I/O to meet complex control requirements. Thus, you get a future-ready setup that’s easy to configure and maintain.

3. Dual-Path, Through-Duct Configuration

Spanning the entire duct diameter, the dual-path setup offers exceptional accuracy. It adjusts for changes in temperature, pressure, and gas composition. Consequently, your readings remain consistent-regardless of gas conditions. In short, it delivers reliable, distortion-free performance in real time.

4. High Precision

Powered by sophisticated integrated circuits, the LEUF-200 achieves high measurement accuracy.

5. Heat–Resistant Design with Low Maintenance

It handles high temperatures: 300 °C in the single-ended version and 260 °C in the through-duct model. With few consumable components, the system reduces maintenance frequency. That means less downtime and lower lifecycle cost.

How Can the LEUF-200 Ultrasonic Flow Meter Tackle Diverse Industrial Applications?

(ESEGAS Ultrasonic Flow Meter LEUF-200)

The LEUF-200 fits a broad range of industrial uses:

- Pipe flow and velocity monitoring: Ideal for closed piping systems and open gas flow environments.

- Flue gas measurement: Suited to ducts handling exhaust gases.

- Stack emissions: Perfect for chimney flow tracking.

You can add optional temperature and pressure sensors to customize your setup. This flexibility ensures accuracy under varying site conditions. Plus, the system performs equally well in both open and closed gas flows—versatile yet reliable.

Conclusion

In summary, the LEUF-200 brings:

- High accuracy: Thanks to ultrasonic sensing and easy calibration.

- Scalability: Through modular design and open communication options.

- Robustness: With heat-resistant sensors and minimal upkeep.

Whether you’re measuring emissions in stacks or tracking flow in core piping, you’ll get reliable data with minimal intervention. The LEUF-200 helps you meet process goals and compliance targets without hassle.

Ready to Learn More? Let’s explore how the LEUF-200 can elevate your processes. Reach out today for deeper technical insight. We’re here to help you streamline operations and boost performance.