Real-time gas monitoring demands speed, selectivity, and stability. Tunable Diode Laser (TDL) gas modules deliver all three factors by harnessing Tunable Diode Laser Absorption Spectroscopy (TDLAS). First, they tune a semiconductor laser to a gas’s unique absorption line. Next, they measure light attenuation with sub-ppm sensitivity and millisecond response. Finally, they convert raw signals into actionable concentration data.

Moreover, this article will:

- Define the TDL gas module and its core components

- Explain the TDLAS principle in clear, industry-standard terms

- Offer a step-by-step roadmap for selecting, installing, and maintaining a module

By the end, you’ll understand how to pick the right laser wavelength, optimize the optical path, and integrate the module into your control system so you can achieve reliable, interference-free gas detection in any demanding environment.

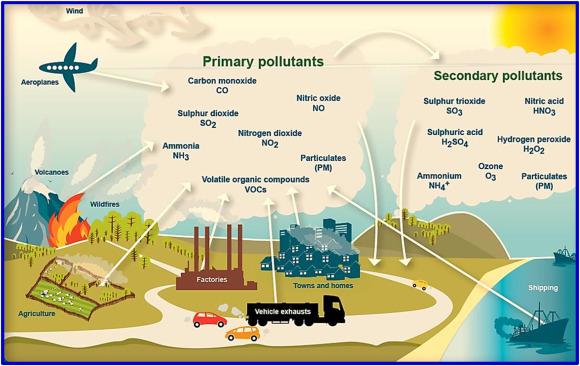

Why Is Precise Gas Monitoring Essential for Industry and the Environment?

(Industrial and environmental gases)

Precise gas monitoring plays a vital role in modern industry and environmental management. Industries rely on accurate measurements to protect workers, optimize processes, and meet strict regulations. Environmental agencies depend on real-time data to control emissions and safeguard natural resources. In short, reliable gas detection ensures safety, efficiency, and sustainability.

Traditional gas-sensing technologies face major hurdles. They often suffer from cross-sensitivity, which leads to false readings. Their response times lag behind real-time needs, and they demand high maintenance. These issues increase operating costs and risk system failures. For example:

- False alarms may trigger unnecessary shutdowns

- Slow responses can miss critical leaks

- Frequent upkeep disrupts continuous monitoring

Today, industries seek compact, fast, and highly selective detectors. They need devices that offer precision, minimal downtime, and easy integration. This demand drives the search for innovative solutions like TDL gas modules. Such modules promise to overcome old challenges and deliver reliable, on-the-spot measurements. For example, ESEGAS ESE-LASER-100M TDL gas module is a good choice. Next, we’ll dive into its architecture and core functions.

What Is a TDL Gas Module?

A. Definition and Core Function

The ESEGAS ESE-LASER-100M TDL gas module integrates a tunable diode laser, gas cell, detector, and control electronics into a compact analyzer. It exploits Tunable Diode Laser Absorption Spectroscopy (TDLAS) to track unique “fingerprint” lines of gases such as NH₃, HCl, HF, H₂S, CH₄, CO, CO₂, and O₂. Thanks to its non-contact optical path, it achieves ppb-level sensitivity and millisecond response, making it ideal for in-situ, real-time monitoring.

Key specifications include:

- Detection Range: from sub-ppm up to several hundred ppm, customizable per gas

- Sensitivity: down to parts-per-billion (ppb)

- Response Time: < 30 s (T₉₀), often < 100 ms with direct-view cells

- Power & Environment: 24 VDC ≤ 15 W; −20 °C to 60 °C; 0.5–2 L/min flow.

TDLAS performance hinges on four metrics: sensitivity, resolution, response time, and stability. Sensitivity defines the lowest detectable concentration, often in ppb. Resolution sets the smallest resolvable concentration change. Response time measures how fast the module updates readings, typically milliseconds. Stability reflects drift over hours or days, which depends on temperature control and electronic noise suppression. Together, these metrics guide module selection and system design.

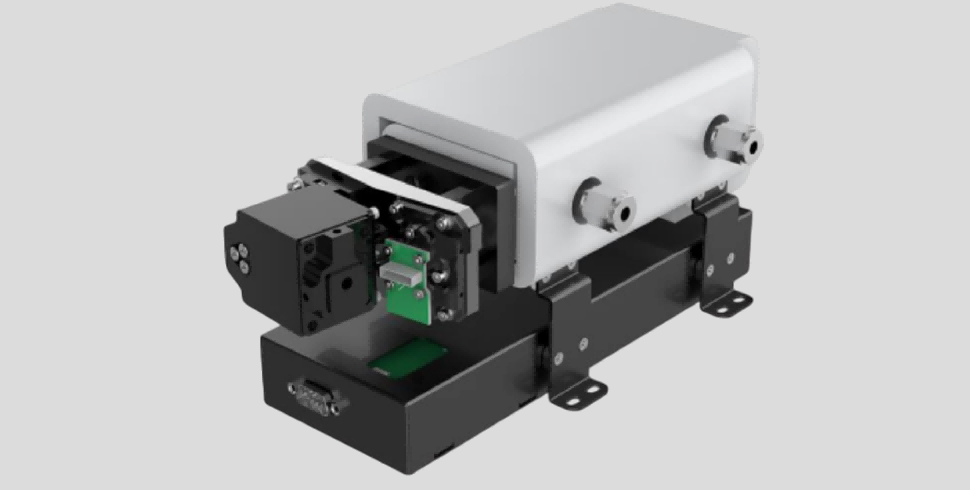

B. Distinction from Standalone TDLAS Systems

(ESE–LASER–100)

Unlike an extractive TDLAS system—which relies on sampling units, pre-treatment trains, and large analysis cabinets—the TDL gas module mounts directly on the process line. The ESE-LASER-100 skips heated sampling and reduces footprint, power draw, and maintenance points. In contrast, standalone systems demand:

- Cabinet Space: Separate control and analysis racks.

- Complex Sampling: High-temperature extraction and transfer lines.

- Long Warm–Up: Up to 30 minutes before stable readings.

The module’s plug-and-play design slashes installation time and cuts operational overhead.

C. Common Industry Applications

(Coal-fired power plant)

TDL gas modules serve a broad range of sectors:

- Power Generation: Coal-fired and waste-to-energy plants monitor NOₓ, SO₂, and HCl.

- Chemical Processing: Real-time control of corrosive gases like HF and NH₃.

- Environmental Monitoring: Trace gas stations track greenhouse gases and VOCs.

- Process Control: Food, pharmaceutical, and semiconductor fabs ensure gas purity.

- Safety & Leak Detection: Oil & gas platforms and refrigeration systems guard against toxic leaks.

These modules deliver reliable, in-situ measurements across demanding environments.

What Are the Key Components Inside a TDL Gas Module?

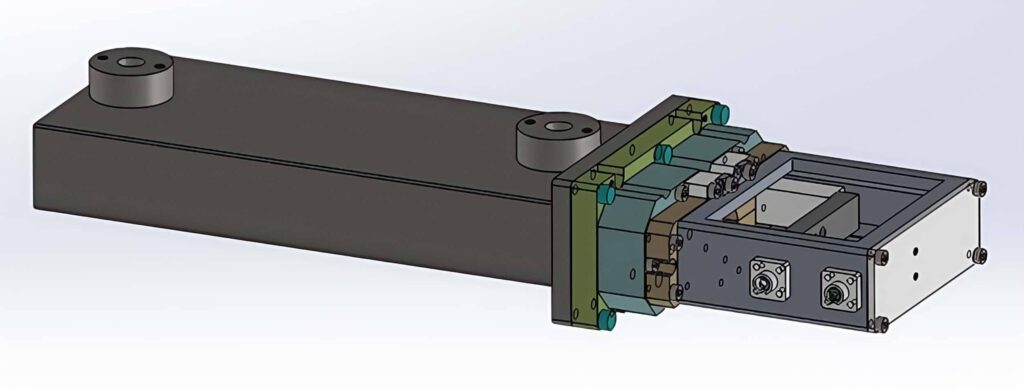

The ESE-LASER-100M comprises four subsystems:

- Optical Bench

- Tunable diode laser (temperature/current tuning)

- Collimation optics and compact gas cell for stable beam alignment

- Electronics

- Precision laser driver and temperature controller

- Modulation unit for wavelength dithering

- Signal Processing

- Lock-in amplifier isolates the absorption harmonic

- Digital filters and onboard firmware compute concentration via Beer–Lambert law

- Mechanical Packaging

- Integrated flow path with quick-connect fittings

- Rugged housing with seals against dust, moisture, and vibration

A. Optical Bench: Laser, Collimation, and Gas Cell

First, the optical bench holds the heart of the analyzer: a tunable diode laser, precision collimation optics, and a compact gas cell. The laser tunes its emission by adjusting temperature and current. Collimating lenses shape the beam into a parallel ray. Meanwhile, the gas cell channels process gas at 0.5–2 L/min through the optical path. This setup maximizes absorption length and ensures stable, sub-ppm detection.

B. Electronics: Driver Circuits, Temperature Control, and Modulation Unit

Next, robust electronics regulate laser output and wavelength scanning. A precision driver board sets injection current with microamp accuracy. A temperature controller maintains the diode junction at a fixed setpoint. A high-frequency modulation unit superimposes a small current dither, enabling single-line absorption measurements every cycle. Together, these circuits deliver repeatable tuning and minimal drift.

C. Signal Processing: Lock–in Amplification, Digital Filtering, and Concentration Computation

Then, the module transforms raw photodiode signals into clean concentration data. A lock-in amplifier isolates the harmonic absorption component and rejects 1/f noise. Digital filters remove baseline drift and residual interference. Finally, onboard firmware applies the Beer–Lambert equation to compute gas concentration in real time. Outputs stream via 4–20 mA or RS-485 for seamless control-system integration.

D. Mechanical Packaging: Flow Management, Mounting, and Environmental Sealing

Finally, rugged packaging ensures long-term reliability. Integrated flow paths with quick-connect fittings simplify gas handling. Built-in mounting brackets let you attach the module directly to pipes or panels. Seals and gaskets protect optics and electronics from dust, moisture, and vibration. As a result, the module thrives in harsh industrial environments with minimal maintenance.

Together, these elements deliver a turnkey, high-selectivity solution for critical gas monitoring.

How to Implement and Maintain a TDL Gas Module: A Practical Step-by-Step Guide?

Step 1: Define Measurement Requirements

First, list your target gas, expected concentration range, and operating environment. Identify the gas matrix and potential interferents. Confirm pressure, temperature, and humidity conditions. Finally, set detection limits and response-time goals. This clarity drives laser selection and optical-path design.

Step 2: Select Laser Wavelength and Path Length

Next, choose a laser tuned to a strong absorption line of your gas. For example, ESEGAS ESE-LASER-100M TDL gas module uses semiconductor laser. Check spectral data for minimal overlap with other species. Then, pick a gas-cell path length that balances sensitivity and size. Longer paths boost sensitivity but enlarge the module. Shorter paths fit tight spaces but need higher laser power.

Step 3: Integrate with Process Control

Then, connect the module to your control system using industry interfaces. Common options include 4–20 mA analog, Modbus RTU/TCP, and OPC. Implement a calibration strategy with zero/span gas bottles or reference cells. Set program alarms and data logging. Finally, test communication and ensure seamless data flow to your SCADA or DCS.

Step 4: Validate Performance

After that, perform zero/span checks to set baseline and full-scale points. Run interference tests using known gas mixtures. Monitor long-term drift by logging readings over days. Compare results against reference analyzers. Adjust calibration factors and document validation outcomes. This step ensures accuracy and regulatory compliance

Step 5: Maintenance Best Practices

Finally, schedule routine checks to keep performance optimal. Inspect laser alignment and clean optical windows. Replace seals and filters as needed. Update firmware for new features and bug fixes. Record all maintenance activities in a log. With these practices, we minimize downtime and extend module life

What Are the Pros and Cons of TDL Gas Module?

A. Advantages

Tunable Diode Laser (TDL) gas modules deliver:

- Unparalleled Selectivity: They target a single absorption line, avoiding false positives.

- Fast Dynamics: Millisecond-scale response captures transient leaks instantly.

- Low Cross–Interference: Wavelength modulation rejects background gases and noise.

Moreover, users gain sub-ppm sensitivity and long-term stability, reducing downtime and boosting confidence in critical measurements.

B. Constraints

However, TDL gas modules face:

- High Initial Cost: Advanced lasers and optics drive up purchase prices.

- Optical Alignment Complexity: Precise beam alignment often requires expert intervention.

- Calibration Demands: Maintaining accuracy needs periodic zero/span checks by trained staff.

These factors can slow deployment and raise total cost of ownership, especially in small-scale operations

What Are the Future Trends of TDL Gas Module?

Looking ahead, TDL gas modules will evolve through:

- Miniaturization: Micro-optics and electronics shrink modules for handheld or drone-based use.

- Multi–Species Sensing: Integrated multi-laser designs will track several gases simultaneously.

- AI–Driven Signal Analysis: Machine-learning algorithms will enhance detection, compensate drift, and predict maintenance.

Together, these innovations promise smarter, more versatile gas monitoring for the next generation of industrial and environmental applications. If you want to know more details about the Tunable Diode Laser Absorption Spectroscopy (TDLAS) principle and the Beer–Lambert law, read our blog “How Does a TDLAS Gas Analyzer Work? A Practical Guide” please! Or contact us please!