Pollution in waste incineration plants can lead to significant environmental and health concerns. Gas analyzers provide a reliable solution to monitor and control harmful emissions, ensuring compliance with strict environmental regulations.

Gas analyzers are essential tools in waste incineration plants, enabling accurate monitoring of emissions such as CO, SO2, and NOx. They help ensure pollution control, operational efficiency, and adherence to legal requirements.

Beyond compliance, gas analyzers enhance safety, efficiency, and sustainability, making them indispensable in modern waste management. This article explores their role and applications in detail.

What Are the Main Pollution Problems in Waste Incineration Plants?

Waste incineration produces a variety of harmful emissions that pose serious risks to human health and the environment. Understanding these pollutants is the first step toward effective control and mitigation.

Key Pollutants Produced in Waste Incineration

| Pollutant | Source | Impact |

| Carbon Monoxide (CO) | Incomplete combustion of carbon-based waste | – Toxic gas that impairs oxygen transport in the blood. – Causes dizziness, headaches, and even death. |

| Sulfur Dioxide (SO2) | Combustion of sulfur-containing materials like plastics and textiles | – Contributes to acid rain, damaging ecosystems. – Exacerbates respiratory illnesses such as asthma. |

| Nitrogen Oxides (NOx) | High-temperature combustion in incinerators | – Leads to smog and acid rain formation. – Causes ground-level ozone, harmful to health and plants. |

| Particulate Matter (PM) | Fly ash and unburned particles from combustion | – Penetrates lungs, causing respiratory and cardiovascular diseases. |

| Dioxins and Furans | Incomplete combustion of chlorinated materials like PVC | – Highly toxic; long-term exposure causes cancer and endocrine disruption. |

| Heavy Metals (e.g., Mercury, Cadmium, Lead) | Incineration of batteries, electronics, and metal-containing waste | – Persistent pollutants accumulating in the environment and food chain. – Causes neurological and developmental disorders. |

Environmental and Health Impacts

Environmental Consequences:

Air Quality Degradation: Pollutants such as NOx, SO2, and particulate matter reduce air quality, affecting urban and rural areas alike.

Soil and Water Contamination: Deposition of heavy metals and dioxins can contaminate soil and water, affecting agriculture and aquatic life.

Climate Change: Waste incineration contributes to greenhouse gas emissions, including CO2 and methane, exacerbating global warming.

Human Health Risks:

Short-Term Effects: Irritation of the eyes, nose, and throat, as well as respiratory problems, are common near waste incineration plants.

Long-Term Effects: Chronic exposure to pollutants like dioxins, heavy metals, and particulate matter increases the risk of cancer, cardiovascular diseases, and developmental disorders.

Challenges in Managing Pollution

- Heterogeneous Waste Composition: Waste streams contain diverse materials, including plastics, metals, and organic matter, which complicate the combustion process and increase pollutant generation.

- Inadequate Combustion Efficiency: Suboptimal combustion leads to the formation of by-products such as CO and dioxins.

- Monitoring and Control Limitations: Traditional methods may fail to detect minute yet critical levels of hazardous emissions, requiring advanced solutions like gas analyzers for real-time monitoring.

By addressing these challenges, waste incineration plants can significantly reduce their environmental and health impacts. Advanced monitoring tools, such as gas analyzers, are essential for achieving this goal.

How Do Gas Analyzers Help Control Emissions?

Gas analyzers are essential tools for managing emissions in waste incineration plants, providing accurate and real-time data to ensure pollution control and compliance with environmental standards.

Gas analyzers work by continuously monitoring key pollutants, such as carbon monoxide (CO), sulfur dioxide (SO2), and nitrogen oxides (NOx), during the combustion process. This real-time data enables plant operators to adjust combustion parameters, ensuring efficient fuel usage and minimizing the release of harmful gases. For example, by optimizing oxygen levels, gas analyzers reduce incomplete combustion, which is a primary cause of CO emissions.

Moreover, these instruments are vital for regulatory compliance. They record and store emission data for reporting purposes, ensuring that pollutant levels remain within legal limits. Advanced systems also feature automatic alarms that alert operators to hazardous conditions, facilitating prompt corrective action.

Gas analyzers do more than meet regulatory requirements—they enhance operational efficiency by identifying inefficiencies in the combustion process, reducing fuel consumption, and lowering maintenance costs. Their role extends beyond pollution control, contributing to environmental sustainability and building public trust in waste management practices.

By integrating gas analyzers into waste incineration plants, operators can effectively control emissions, reduce environmental impact, and ensure safer, more efficient operations.

- Real-Time Monitoring:

- Gas analyzers continuously measure gas concentrations, offering real-time insights.

- This enables operators to adjust combustion parameters and reduce emissions promptly.

- Compliance Assurance:

- They help plants adhere to environmental regulations by ensuring pollutant levels remain within permissible limits.

- Enhanced Safety:

- Automated alarms signal dangerous emission levels, preventing accidents.

- Accurate monitoring minimizes risks associated with toxic gases.

Through these features, gas analyzers not only protect the environment but also enhance plant safety and operational efficiency.

Types of Emissions Controlled by Gas Analyzers

- Carbon Monoxide (CO): Monitors incomplete combustion to ensure efficient fuel usage and reduce toxicity.

- Sulfur Dioxide (SO2): Helps control acidic emissions to prevent acid rain formation.

- Nitrogen Oxides (NOx): Tracks and minimizes NOx levels, reducing contributions to smog and ozone formation.

- Oxygen (O2): Ensures optimal oxygen levels for complete combustion, reducing the release of unburned pollutants.

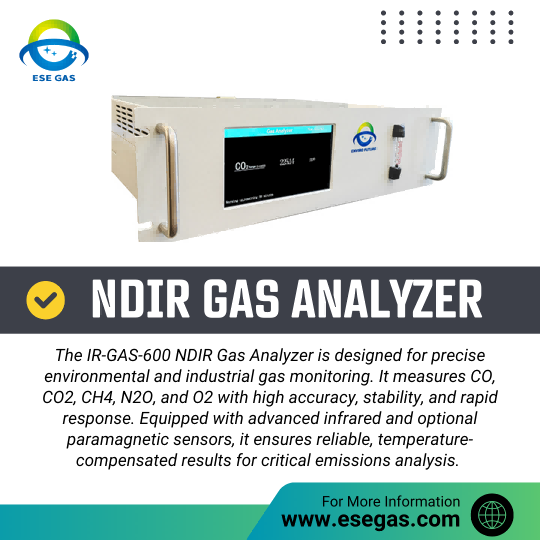

What Technologies Are Commonly Used in Gas Analyzers?

Different technologies are used depending on the specific requirements of waste incineration plants.

- Optical Gas Analysis:

- Technologies such as Fourier Transform Infrared (FTIR) and Non-Dispersive Infrared (NDIR) spectroscopy detect multiple gases simultaneously.

- These methods are ideal for monitoring complex mixtures of pollutants.

- Electrochemical Sensors:

- These sensors measure specific gases like CO and SO2 with high sensitivity.

- They are compact, cost-effective, and widely used in industrial applications.

- Paramagnetic and Zirconia Sensors:

- Paramagnetic sensors measure oxygen levels accurately, optimizing combustion efficiency.

- Zirconia-based analyzers are robust and suitable for high-temperature environments.

The choice of technology depends on factors like the plant’s operational needs and the types of gases to be monitored.

Why Is Continuous Emission Monitoring Essential?

- Regulatory Necessity: CEMS are often mandated by environmental agencies to monitor and report emissions in real-time.

- Data Transparency: They record and store emission data, enabling accurate reporting for audits and certifications. Transparency builds public trust in waste management practices.

- Operational Insights: CEMS data helps identify inefficiencies, optimize combustion, and reduce fuel consumption.

Continuous monitoring not only ensures compliance but also promotes sustainable and efficient operations.

How Do Gas Analyzers Contribute to Sustainability?

Gas analyzers play a key role in reducing the environmental impact of waste incineration.

- Optimizing Combustion: By monitoring oxygen levels, analyzers ensure complete combustion, minimizing the release of unburned gases. This reduces fuel waste and associated greenhouse gas emissions.

- Energy Recovery: Effective monitoring enhances the waste-to-energy process, maximizing energy extraction from waste.

- Minimizing Toxic Emissions: Continuous monitoring ensures pollutant levels are kept in check, reducing the risk of environmental harm.

These benefits position gas analyzers as critical tools for achieving sustainability goals in waste management.

Conclusion

Gas analyzers are indispensable in waste incineration plants, offering solutions to monitor, control, and reduce harmful emissions. By ensuring regulatory compliance, improving efficiency, and supporting sustainability, they form the backbone of modern waste-to-energy facilities. Investing in advanced gas analysis technology is essential for a cleaner, greener future.

If you have any questions, don’t hesitate to contact us; we will respond as soon as possible!