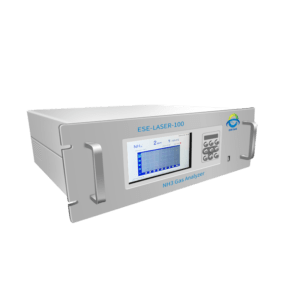

Measurement and monitoring of ammonia (NH3) is critical in a variety of fields including environmental monitoring, industrial production control, and safety monitoring. Not only is ammonia potentially hazardous to human health, but in many chemical and industrial processes, accurate ammonia concentration monitoring is equally important to ensure production efficiency and environmental protection. In these application scenarios, laser NH3 analyzers are the technology of choice due to their high accuracy, sensitivity, and fast response time. However, sensors are often interfered with by a variety of factors during the measurement process, with moisture being one of the most common interferences. In this article, we will explore the working mechanism of laser NH3 analyzers and why they are effective in avoiding moisture interference and ensuring accurate measurement results.

How Laser NH3 Gas Analyzers Work

Laser NH3 gas analyzers rely heavily on modulated spectral absorption (TDLAS) or other laser technologies such as quantum cascade lasers (QCL). These techniques determine gas concentration by measuring how much of a gas absorbs a specific wavelength of laser light. Each gas has a unique absorption fingerprint by which the concentration of a particular gas can be accurately identified and measured, and the method is highly selective, enabling accurate identification of target gases in complex gas mixtures.

Interference Mechanisms of Moisture on Laser NH3 Gas Analyzers

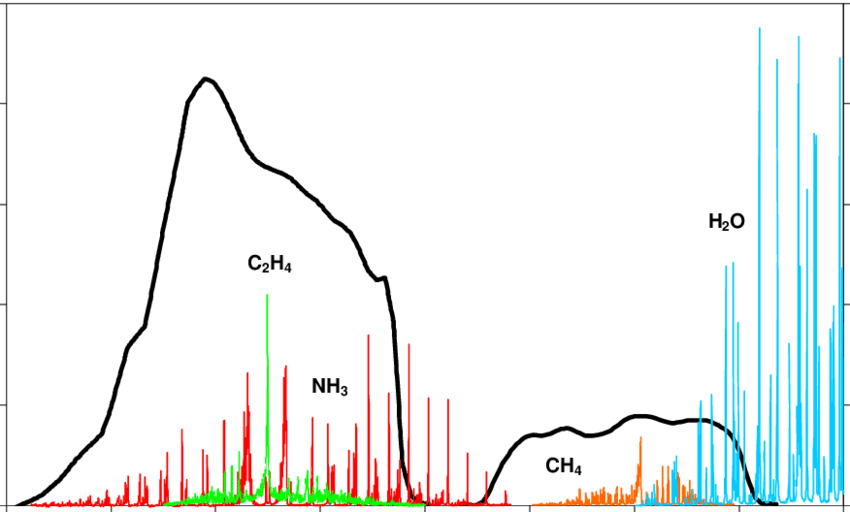

The interference of moisture to the laser NH3 gas analyzer occurs mainly through two ways: absorption and scattering. Firstly, water molecules have strong absorption properties in the atmosphere, especially in the near-infrared and infrared bands, and their absorption spectral bands overlap with those of NH3, which makes the measurement signals of the laser NH3 gas analyzer disturbed by moisture. Secondly, water molecules may also cause scattering of light, which in turn affects the intensity of the laser light passing through the sample gas, resulting in variations in the NH3 measurement signal. These interference mechanisms make moisture an important factor in the measurement accuracy of laser NH3 gas analyzers.

Interference of Moisture with Laser NH3 Analyzers

In the working principle of the laser NH3gas analyzer, the presence of moisture can lead to several types of disturbances:

- Absorption overlap: The absorption bands of moisture overlap with those of ammonia, which may result in signal aliasing, making it impossible to accurately measure the concentration of NH3.

- Signal attenuation: Moisture absorbs the laser, causing attenuation of the laser, which affects the light intensity of the laser through the sample gas and thus the NH3 measurement signal.

- Spectral overlap: The presence of moisture may cause the absorption spectrum of ammonia to change, resulting in the laser NH3 analyzer not being able to accurately identify the absorption peaks of NH3.

The Prescription of Moisture on Laser NH3 Gas Analyzers

In response to the above disturbances, the following measures can be taken to reduce the effect of moisture on the laser NH3 analyzer:

- Gas pre-treatment: Before the sample gas enters the laser NH3 analyzer, the gas can be pre-treated, e.g. by removing moisture through a desiccant or condenser. This reduces the effect of moisture on the analyzer and improves the accuracy of the measurement.

- Optical path design: Reasonable design of the optical path of the laser NH3 analyzer to avoid the absorption of the laser by moisture. Optical path separation, increasing the length of the optical path, and other methods can be used to reduce the impact of moisture on the laser.

- Multi-wavelength Measurement: The use of multi-wavelength measurement techniques allows the interference of moisture with the NH3 measurement signal to be identified and eliminated. By measuring signals at multiple wavelengths simultaneously, the effects of moisture can be separated from the NH3 signal, improving the accuracy of the measurement.

- Software calibration: Using software calibration, the interference of moisture on the NH3 measurement signal is taken into consideration and corrective calculations are made to improve the accuracy and reliability of the measurement results.

- Environmental control: In practical applications, reasonable control of environmental conditions is also an important means of reducing moisture interference. Such as controlling the temperature and humidity, to avoid excessive moisture content in the sample gas, thus reducing the impact of moisture on the laser NH3 analyzer.

Moisture Interference Test Report of Our NH3 Gas Analyzer

H2O absorbs many spectral lines in the near-infrared and mid-infrared spectrum, and there is cross interference for many gases. To determine the influence of water on the target compounds, the compilation team carried out the water interference test. The test scheme is to connect the calibration device of high temperature and standard humidity with the analyzer to ensure that the air circuit connection does not leak. After the instrument is turned on and stable, the standard gas of the target is passed, and the moisture content is controlled by adjusting the high-temperature standard humidity calibration device. After the displayed value is stable, the standard gas value is read, the measurement is repeated three times, and the average value is taken as the measurement result.

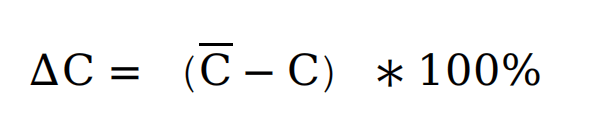

The 5%, 15%, and 30% moisture content were selected to verify the interference of the instrument in the zero-point working state. The indicative error is calculated according to the following formula.

In the formula:

∆C — the value error, mg/m3.

— The average value of the standard gas determination results, mg/m3.

C — Standard gas concentration value, mg/m3.

The H2O interference test results are shown in Table 5-15~ Table 5-19. The test results show that different moisture content to NH3 and HCl is less than 2 mg/m3, and the instrument has good anti-moisture interference ability.

Table 5-15 Z23GL 58J004 Water interference test data

| Calibrating Gas | Measurement Frequency | H2O Content (%) | Actual H2O Content(%) | NH3, Determination Value (mg/m3) | Indicating Error(mg/m3) | |

| Name | Nominal Value (mg/m3) | |||||

| NH3 | 0 | 1 | 5% | 5.06 | 0.07 | 0.06 |

| 2 | 5.27 | 0.05 | ||||

| 3 | 5.16 | 0.06 | ||||

| 1 | 15% | 15.14 | 0.07 | 0.02 | ||

| 2 | 15.1 | 0.02 | ||||

| 3 | 15.19 | -0.04 | ||||

| 1 | 30% | 29.84 | -0.09 | -0.06 | ||

| 2 | 29.91 | -0.11 | ||||

| 3 | 30.19 | 0.03 | ||||

Table 5-16 YNBB 01021 Water interference test data

| Calibrating Gas | Measurement Frequency | H2O Content (%) | Actual H2O Content(%) | NH3, Determination Value (mg/m3) | Value Error (mg/m3) | |

| Name | Nominal Value (mg/m3) | |||||

| NH3 | 0 | 1 | 5% | 5.15 | 0.1 | 0.08 |

| 2 | 5.2 | 0.09 | ||||

| 3 | 5.06 | 0.05 | ||||

| 1 | 15% | 15.12 | 0.06 | 0.03 | ||

| 2 | 15.08 | 0.05 | ||||

| 3 | 15.17 | -0.02 | ||||

| 1 | 30% | 29.92 | -0.08 | -0.04 | ||

| 2 | 29.83 | -0.07 | ||||

| 3 | 30.16 | 0.02 | ||||

Table 5-17 5M01000148 Water interference test data

| Calibrating Gas | Measurement Frequency | H2O Content (%) | Actual H2O Content(%) | NH3, Determination Value (mg/m3) | Value Error (mg/m3) | |

| Name | Nominal Value (mg/m3) | |||||

| NH3 | 0 | 1 | 5% | 5.13 | 0.1 | 0.07 |

| 2 | 4.95 | 0 | ||||

| 3 | 4.87 | 0.1 | ||||

| 1 | 15% | 14.83 | 0 | 0 | ||

| 2 | 14.96 | 0 | ||||

| 3 | 15.14 | 0 | ||||

| 1 | 30% | 30.42 | 0 | 0 | ||

| 2 | 30.15 | 0 | ||||

| 3 | 29.81 | 0 | ||||

Table 5-18 Z23GL 58H001 Water interference test data

| Calibrating Gas | Measurement Frequency | H2O Content (%) | Actual H2O Content(%) | NH3, Determination Value (mg/m3) | Value Error (mg/m3) | |

| Name | Nominal Value (mg/m3) | |||||

| HCl | 0 | 1 | 5% | 5.14 | -0.11 | -0.09 |

| 2 | 5.16 | -0.1 | ||||

| 3 | 5.19 | -0.06 | ||||

| 1 | 15% | 15.1 | -0.07 | -0.06 | ||

| 2 | 14.99 | -0.08 | ||||

| 3 | 15.05 | -0.04 | ||||

| 1 | 30% | 30.19 | -0.02 | 0.02 | ||

| 2 | 30.1 | 0.02 | ||||

| 3 | 30.07 | 0.05 | ||||

Moisture Interference Overcoming

- Advanced laser technology

The Laser NH3 Analyzer significantly reduces interference from water vapor absorption bands by employing specific wavelengths of laser light that precisely target the absorption lines of ammonia. These specific wavelengths are carefully selected to be located in the spectral region where moisture absorption is weak or has little or no effect, ensuring accurate and repeatable measurements. - Spectral resolution technology

The laser NH3 analyzer can distinguish between the absorption characteristics of ammonia and water vapor by means of a high-resolution spectral analysis technique. This technology relies on advanced algorithms and big data analysis to identify and separate the spectral signatures of ammonia and water, ensuring highly accurate ammonia measurements that maintain excellent performance even in high-humidity environments. - Temperature and moisture control technology

To further minimize the effects of moisture, the laser NH3 analyzer uses temperature and humidity control technology. By precisely controlling the temperature and humidity inside the analyzer, water vapor is prevented from condensing on the optical components while maintaining the stability of the gas sample. This not only reduces moisture interference but also improves measurement accuracy and reliability. - Calibration and compensation algorithms

The Laser NH3 Analyzer also employs sophisticated calibration and compensation algorithms to automatically correct for any interference that may be caused by moisture. These algorithms are based on extensive experimental data and mathematical models that allow for real-time adjustments to the measurement results, ensuring that highly accurate analytical data is available under varying environmental conditions.

Conclude

Test reports show that Moisture does not interfere with our TDLAS NH3 gas analyzers.

Moisture, as a common interfering factor in ammonia analysis, may have a certain impact on the measurement accuracy of the laser NH3 analyzer. However, through reasonable pre-processing, optical path design, multi-wavelength measurement, software correction, and environmental control measures, the interference of moisture can be effectively reduced to improve the measurement accuracy and stability of the laser NH3 analyzer, to meet the needs of ammonia gas monitoring better. In practical application, it is necessary to choose the appropriate solution according to the specific situation and optimize and adjust it with the actual situation to ensure the accuracy and reliability of the monitoring results.