Navigating the complex world of Syngas Analyzers demands are keen insight. This guide illuminates key factors: sensor accuracy, calibration frequency, multi-gas detection capabilities. Essential components like IR spectrometers, electrochemical cells, and micro-flow valves are dissected.

Delving into operational specifics, from gas specificity to environmental adaptability, equips decision-makers. Advanced technologies, real-time data analysis, and durability considerations are explored. This journey ensures informed choices in Syngas Analyzer selection, pivotal for facility efficiency.

What Is Syngas Analysis?

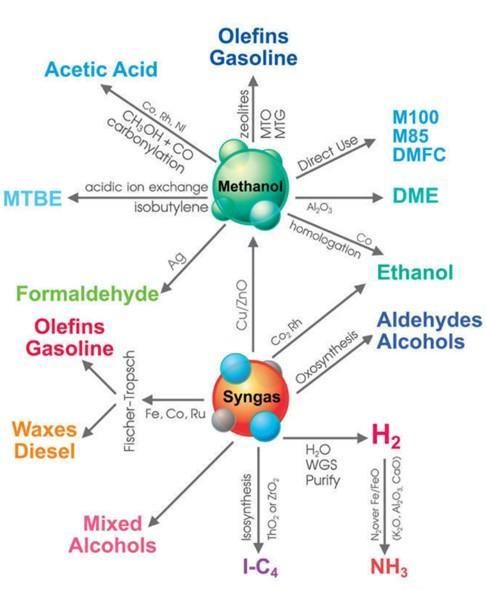

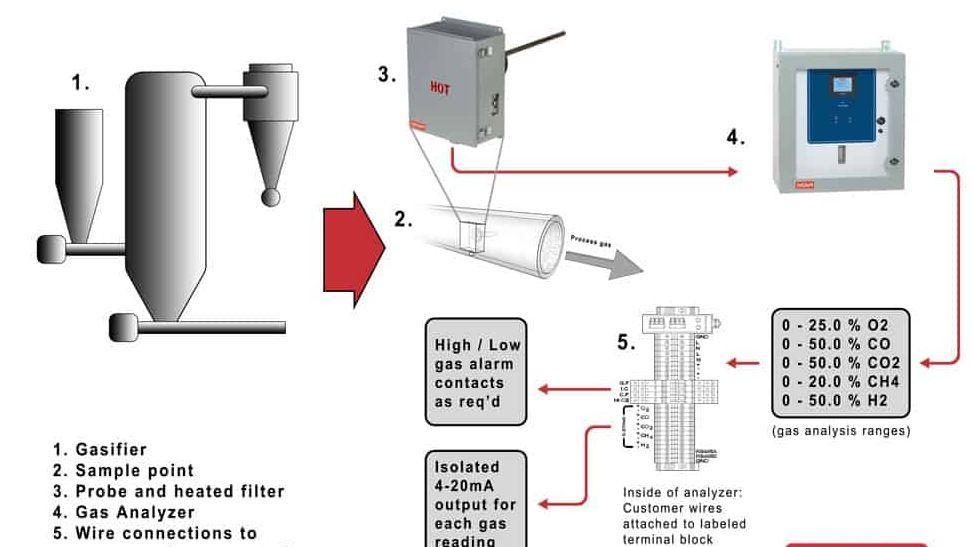

Syngas analysis, pivotal in energy sectors, utilizes advanced analyzers. These devices, complex in design, boast arrays of sensors for precise gas measurement. Typically, Syngas Analyzers feature robust components like micro-flow valves, IR spectrometers, and electrochemical cells.

Critical metrics analyzed include CO, CO₂, CH₄ levels, H₂ concentration, and O₂ percentages. Engineers favor these analyzers for their efficiency in monitoring gasification processes. Calibration routines, integral for accuracy, involve known gas mixtures. Real-time data processing, enabled by sophisticated algorithms, enhances operational decisions.

Maintenance demands, though significant, are offset by the analyzer’s longevity and reliability. In essence, Syngas Analyzers are indispensable tools, transforming raw data into actionable insights in energy production.

Types of Syngas Analyzers!

· Paramagnetic Gas Analyzers

Paramagnetic Gas Analyzers excel in O₂ concentration evaluation. Utilizing magnetic fields, they detect changes in gas magnetism. Key components include magnetic coils, sensitive detection chambers, and advanced signal processors. Their precision in O₂ quantification aids in optimizing combustion processes. Preferred in industries for their reliability, these analyzers ensure optimal fuel-to-air ratios.

· Infrared/UV Absorption Gas Analysis

Infrared/UV Absorption Gas Analysis leverages light absorption properties. Gases like CO, CO₂ absorb specific light wavelengths, measured by this method. Essential parts: UV lamps, IR emitters, photodetectors. Industries value these for their non-invasive nature and continuous monitoring capability. They play a crucial role in emissions control.

· Flame Ionization Detectors (FID)

Flame Ionization Detectors are paramount for hydrocarbon analysis. They operate by ionizing organic compounds in flame, measuring ion currents. FID‘s key elements: hydrogen flame source, ion collector plates. Their high sensitivity makes them ideal for trace hydrocarbon detection. Widely used in environmental monitoring, FIDs ensure regulatory compliance.

· Photoacoustic Spectroscopy (PAS)

Photoacoustic Spectroscopy Instruments use sound waves generated by light absorption. Components include modulated light sources, microphones. PAS excels in detecting low concentration gases, benefiting atmospheric studies. Its non-intrusive nature preserves sample integrity. Industries favor PAS for its precision in trace gas analysis.

· Electrochemical Cells

Electrochemical Cells analyze gases through chemical reactions. They consist of electrodes and electrolytes. Widely used for O₂, toxic gases detection. Their compact size, low power requirement make them suitable for portable analyzers. Key in safety applications, these cells provide rapid, reliable gas detection.

· Gas Chromatography (GC)

Gas Chromatography separates complex gas mixtures. Essential components: columns, detectors, carrier gas system. GC excels in identifying individual compounds. Critical in quality control, it aids in ensuring product purity. Its versatility allows adaptation to various industrial applications, from pharmaceuticals to petrochemicals.

· Mass Spectrometry (MS)

Mass Spectrometry identifies compounds by mass-to-charge ratio. Key parts: ionization source, mass analyzer, detector. MS’s high sensitivity and accuracy benefit research and diagnostics. Its ability to analyze complex mixtures makes it indispensable in analytical chemistry. Industries rely on MS for detailed chemical composition analysis.

· Ion Mobility Spectrometry (IMS)

Ion Mobility Spectrometry detects ions based on mobility in electric field. Components include drift tubes, ion sources. Renowned for rapid detection, IMS is pivotal in security screening. Its portability and speed are crucial in field applications, from explosives to narcotics detection.

· Laser Diode Photoacoustic Infrared Gas Analyzer

Laser Diode Photoacoustic Infrared Gas Analyzer utilizes laser diodes for precise gas measurement. Key features: laser sources, acoustic detectors. Its specificity in gas detection aids in environmental monitoring. Preferred for its high accuracy, it plays a significant role in industrial emissions control.

· Photoionization Detectors (PIDs)

Photoionization Detectors measure volatile organic compounds. They ionize gases using UV light. Essential parts: UV lamps, ionization chambers. PIDs are vital in hazardous material identification. Their sensitivity to a wide range of compounds makes them indispensable in environmental and safety applications.

| Feature \ Analyzer Type | Infrared/UV Absorption | Flame Ionization Detector (FID) | Gas Chromatography (GC) | Mass Spectrometry (MS) | Ion Mobility Spectrometry (IMS) | Laser Diode Photoacoustic IR |

| Detection Principle | Absorption of IR/UV light | Ionization in flame | Separation by molecular properties | Mass-to-charge ratio analysis | Ion mobility in electric field | IR absorption and photoacoustic effect |

| Sensitivity (ppm) | 1-10 | <1 | 0.1-10 | <1 | 0.01-1 | 0.1-1 |

| Response Time (sec) | 10-30 | 1-10 | 30-600 | 10-100 | 1-10 | 10-30 |

| Applications | General gas analysis | Hydrocarbons, VOCs | Complex mixtures | Broad range, isotope analysis | Trace detection, security | Environmental monitoring |

| Maintenance Level | Moderate | High | High | High | Moderate | Low |

| Advantages | Non-specific, robust | High sensitivity for hydrocarbons | Precise separation | High precision, isotope data | Fast, portable | Non-invasive, accurate |

Key Factors in Choosing a Syngas Analyzer!

· Gas Specificity

In Syngas gas analyzers ensures accurate target gas detection. Selectivity towards gases like CO, CO₂, and CH₄ is critical. Advanced sensors, calibrated for specific gas responses, facilitate this. Industries rely on this specificity for process optimization. Accurate gas identification prevents erroneous data, enhancing system efficiency.

· Sensitivity Levels

In Syngas Analyzers are paramount for precise measurements. High sensitivity ensures detection of low concentration gases. Utilizing fine-tuned sensors and amplifiers, analyzers detect minute changes. This feature is vital in monitoring trace gases, aiding in environmental compliance and safety.

· Measurement Speed

Measurement Speed of Syngas Analyzers impacts operational efficiency. Rapid response times enable quick process adjustments. Key in dynamic environments, fast measurements prevents delays. Integrating high-speed processors and real-time algorithms, these analyzers provide immediate data insights. Fast data acquisition is crucial for timely decision-making.

· Environmental Compatibility

Environmental Compatibility of Syngas Analyzers is essential for diverse conditions. Designed to withstand varying temperatures, humidity, they ensure consistent performance.

Robust build, resistance to corrosive gases, are key. This adaptability is crucial in harsh industrial settings, maintaining analyzer accuracy and reliability.

· Maintenance Ease

In Syngas Analyzers reduces operational downtimes. User-friendly interfaces, modular designs facilitate easy servicing. Regular calibration, sensor replacement are streamlined. Simplified maintenance procedures ensure continuous, uninterrupted analyzer operation. This convenience is highly valued in industries for sustaining productivity.

· Operational Longevity

Operational Longevity of Syngas Analyzers affects long-term reliability. Durable components, robust construction extend lifespan. Longevity reduces frequent replacement needs, ensuring cost savings. Industries favor analyzers with proven durability, as they guarantee consistent performance over years.

· Cost-Efficiency

Cost-Efficiency in Syngas Analyzers is a determining factor. Balancing initial investment with operational expenses is key. Analyzers offering low running costs, minimal maintenance are preferred. Cost-effective solutions that do not compromise on quality or performance are sought after in budget-conscious sectors.

Best Practices For Installing And Operating A Syngas Analyzer!

· Accurate Calibration

Accurate Calibration is pivotal for precise gas measurements. Utilizing known gas mixtures, calibration aligns gas sensor responses. Regular recalibration, following specific intervals, maintains accuracy. Advanced calibration techniques involve multi-point checks, ensuring a broad range of accuracy. This step is fundamental in guaranteeing data reliability in gas analysis.

· Safety Compliance

Safety Compliance is non-negotiable in analyzer operation. Adhering to industry safety standards prevents hazardous incidents. Regular safety inspections, ensuring compliance with regulations, are mandatory. Implementing fail-safes, emergency shutdown systems, enhances safety.

· User Training

User Training ensures effective and safe analyzer use. Comprehensive training covers operation, maintenance, safety procedures. Continuous learning updates on latest practices and technology advancements. Empowering users with in-depth knowledge enhances operational efficiency. Well-trained personnel are fundamental for the successful implementation of gas analysis systems.

· Regular Maintenance

Maintenance ensures the continuity of analyzer performance. Some key maintenance activities are sensor cleaning and gas filter replacement. Scheduled checks prevent unexpected malfunctions.

With precise maintenance logs, it is possible to track wear and tear. A proactive maintenance strategy prolongs the life of operation by the analyzer in question. Maintenance is essential to ensure consistent and accurate readings.

· Optimal Placement

The best position for the analyzer is where it performs most effectively. Strategic positioning near the gas sources increases response time. It is also critical not to allow extreme temperature changes, dust and moisture. Accessibility for maintenance is another factor to consider in terms of placement.

By positioning the analyzer based on operational conditions, it is possible to make sure its efficiency.

· Ambient Control

Consistency in readings requires ambient control. Environmental parameters such as temperature and relative humidity influence sensor accuracy.

Stabilizing these conditions requires an implementation of measures. Hence, the utilization of enclosures or climate control systems in installations where analyzers are used is beneficial. As a result, the controlled environment keeps gas analysis precise and repeatable.

· Data Verification

Data Verification enhances measurement confidence. Verification of accuracy is achieved by correlation between analyzer data and known standards. Redundancy, through the use of more than analyzer for a given measurement can help to validate results.

Data checks and comparing against historical trends help to maintain integrity. In critical gas analysis operations, verified data accuracy is essential.

How To Effectively Use Data from Syngas Analyzers For Process Optimization?

· Trend Analysis

Trend Analysis with data from analyzers identifies operational patterns. Long-term data compilation reveals efficiency fluctuations. Analyzing trends in CO, CO₂ levels aids in combustion optimization.

Trend-based insights guide process adjustments, enhancing overall system performance. This analytical approach is crucial for identifying operational inefficiencies and potential improvements.

· Real-Time Monitoring

Real-Time Monitoring offers immediate data insights. Continuous data flow allows for instant decision-making. Monitoring parameters like H₂, O₂ levels enable swift process adjustments.

Real-time data is key in dynamic process environments, ensuring optimal conditions. This immediacy is vital for maintaining consistent quality and efficiency.

· Data Integration

Data Integration consolidates information for comprehensive analysis. Merging analyzer data with operational metrics offers a complete view.

Integrated data analysis enhances understanding of process interactions. This holistic approach facilitates informed decision-making, improving overall system performance. Integrated data is essential for effective process management and optimization.

· Process Adjustment

Process Adjustment based on analyzer data ensures optimal operation. Adjusting variables in response to gas composition changes maintains efficiency.

Data-driven adjustments optimize fuel consumption, reduce emissions. This approach is fundamental in achieving sustainable and efficient operation. Process adjustments based on data insights are key to operational excellence.

· Efficiency Tracking

Efficiency Tracking measures the impact of process changes. Tracking changes in gas composition, energy output evaluates efficiency gains. Efficiency metrics guide continuous improvement initiatives.

Consistent tracking is critical for long-term process optimization. This focus on efficiency ensures sustainable and cost-effective operation.

· Predictive Maintenance

Predictive Maintenance anticipates equipment needs. Analyzing data trends predicts sensor degradation, maintenance requirements. This proactive approach prevents unexpected downtimes.

Predictive maintenance is essential for sustained operational efficiency. It enhances equipment longevity and reliability through timely interventions.

· Quality Control

Quality Control ensures product consistency. Monitoring syngas composition verifies product specifications. Continuous quality checks maintain high standards.

Quality control based on precise data ensures superior end products. This focus on quality is fundamental in meeting industry standards and customer expectations.

FAQs!

Q. How to ensure accurate measurements?

A. To ensure accurate measurements, rigorous calibration is key. Use known gas mixtures for aligning sensor responses. Regular checks, recalibration maintain precision.

Advanced techniques like multi-point calibration broaden accuracy range. Ensuring sensors are clean, free of contaminants is crucial. Optimal environmental conditions stabilize measurements, enhancing accuracy.

Q. What are common challenges in syngas analysis?

A. Common challenges in syngas analysis include variable gas compositions, sensor sensitivity. Diverse gas mixtures require adaptable analysis techniques. Sensor degradation over time affects accuracy.

Interfering substances can lead to erroneous readings. Maintaining consistent sample flow, temperature, pressure is challenging. Overcoming these requires robust, adaptable analyzer designs and regular maintenance.

Q. How often should syngas analyzers be calibrated?

A. Syngas analyzers should be calibrated at specific intervals for accuracy. Frequency depends on usage intensity, environmental conditions. Regular recalibration, ideally monthly or quarterly, is recommended. Calibration schedules vary based on operational demands, gas types.

Sticking to manufacturer guidelines ensures sustained accuracy and reliability.

Q. Can syngas analyzers detect multiple gases simultaneously?

A. Syngas analyzers can detect multiple gases simultaneously. Advanced models integrate various sensors for different gases. Multiplexing capabilities allow for concurrent measurements.

This simultaneous detection is crucial for comprehensive gas analysis. It enhances efficiency, providing a complete overview of gas composition in one analysis cycle.

Conclusion

The right Syngas Analyzer transforms facility operations. Key considerations, from sensor precision to technological advancements, have been unraveled. Emphasizing regular calibration, multi-gas detection, and robust construction, this guide serves as a beacon for optimal selection. For further expertise and specialized solutions, visit ESEGAS where precision meets technology in gas analysis.