Are you looking for an accurate and reliable method to monitor gas concentrations? Traditional methods often fall short, especially in harsh environments. The UV-DOAS gas analyzer offers a high-precision solution for real-time gas detection.

A UV-DOAS gas analyzer is an advanced instrument that uses ultraviolet differential optical absorption spectroscopy (UV-DOAS) to measure gas concentrations in various environments. It provides fast, accurate, and reliable data for monitoring multiple gas components, even in challenging conditions.

Despite the clear advantages, many are unaware of how this technology operates or how it compares to traditional methods. By understanding its working principle and applications, you can make an informed choice for your monitoring needs.

How Does a UV-DOAS Gas Analyzer Work?

The UV-DOAS gas analyzer works on the principle of ultraviolet differential optical absorption spectroscopy, or UV-DOAS. This method involves passing ultraviolet light through a gas sample and measuring the absorption of the light at different wavelengths. Gases absorb UV light at specific wavelengths, allowing the analyzer to deify the presence of various components with high accuracy.

Traditional gas analyzers often rely on chemical sensors or infrared absorption, which may lack the sensitivity needed for certain applications. By contrast, UV-DOAS technology excels at detecting even low concentrations of gases like sulfur dioxide (SO₂), nitrogen oxides (NOx), and ozone (O₃), thanks to its broad detection spectrum and high sensitivity. This makes UV-DOAS particular in applications that demand precision, such as environmental monitoring, industrial process control, and emissions monitoring.

What Are the Key Applications of a UV-DOAS Gas Analyzer?

UV-DOAS gas analyzers find widespread application across various industries due to their high accuracy and versatility. Here are some of the most common uses:

Environmental Monitoring

UV-DOAS is commonly used to monitor air quality and compliance with environmental regulations. It is particularly effective in detecting harmful pollutants like sulfur dioxide, nitrogen oxides, and ozone, which can impact public health and the environment.

Industrial Process Monitoring

Many industries rely on accurate gas monitoring to optimize production processes and maintain safety standards. The UV-DOAS gas analyzer can monitor gas concentrations in real time, providing critical data for industries such as petrochemicals, power generation, and cement production. This allows for efficient process control and helps prevent accidents caused by dangerous gas levels.

Emission Control and Compliance

In sectors like power generation and heavy industry, monitoring and controlling emissions is a requirement. The UV-DOAS gas analyzer enables facilities to track emissions with precision, ensuring they meet local and international environmental standards. This not only helps avoid fines but also contributes to a company’s sustainability goals.

Research and Development

UV-DOAS is often used in scientific research, especially in studying atmospheric chemistry. Researchers use it to measure trace gases in the atmosphere, helping to understand phenomena like smog formation, acid rain, and climate change.

What Advantages Does UV-DOAS Offer Compared to Traditional Gas Analyzers?

UV-DOAS gas analyzers have several distinct advantages over traditional gas detection methods, particularly in terms of sensitivity, accuracy, and the ability to detect multiple gases simultaneously.

- High Sensitivity and Accuracy: One of the major strengths of UV-DOAS technology is its ability to detect gases at deficient concentrations. This is crucial in environmental monitoring, where even trace amounts of pollutants can have significant impacts on public health and ecosystems. Compared to traditional infrared or electrochemical methods, UV-DOAS offers far greater sensitivity, making it ideal for detecting gases like ozone or sulfur dioxide that absorb light in the ultraviolet range.

- Simultaneous Multi-Component Detection: Unlike other gas analyzers that may focus on detecting a single gas, UV-DOAS can measure multiple gases simultaneously without interference. This is a key advantage in applications such as emissions monitoring, where the presence of multiple gases needs to be tracked at once. The wide spectral range of UV-DOAS ensures that all relevant gases can be accurately measured in a single pass, improving efficiency and reducing the need for multiple instruments.

- No Cross-Sensitivity Issues: Traditional gas analyzers often suffer from cross-sensitivity, where one gas’s presence affects another’s measurement. This can lead to inaccurate results and missed detections. UV-DOAS, however, is highly selective for the gases it measures, virtually eliminating cross-sensitivity. This makes it a more reliable choice for critical applications where precision is paramount.

- Real-Time Data Collection: In many industrial and environmental applications, real-time data is essential for maintaining safety and compliance. UV-DOAS gas analyzers provide continuous, real-time monitoring of gas concentrations, allowing for immediate response to any changes in gas levels. This is particularly important in industries like power generation or petrochemicals, where dangerous gas buildups can occur suddenly.

- Robust Performance in Harsh Conditions: Another advantage of UV-DOAS gas analyzers is their ability to function reliably in harsh environmental conditions. Whether exposed to high temperatures, humidity, or corrosive gases, UV-DOAS systems can deliver consistent, accurate results where other methods may fail. This makes them ideal for use in industries like mining, cement production, or chemical manufacturing, where environmental challenges are a constant factor.

UV-GAS-100M UV-DOAS Gas Sensor

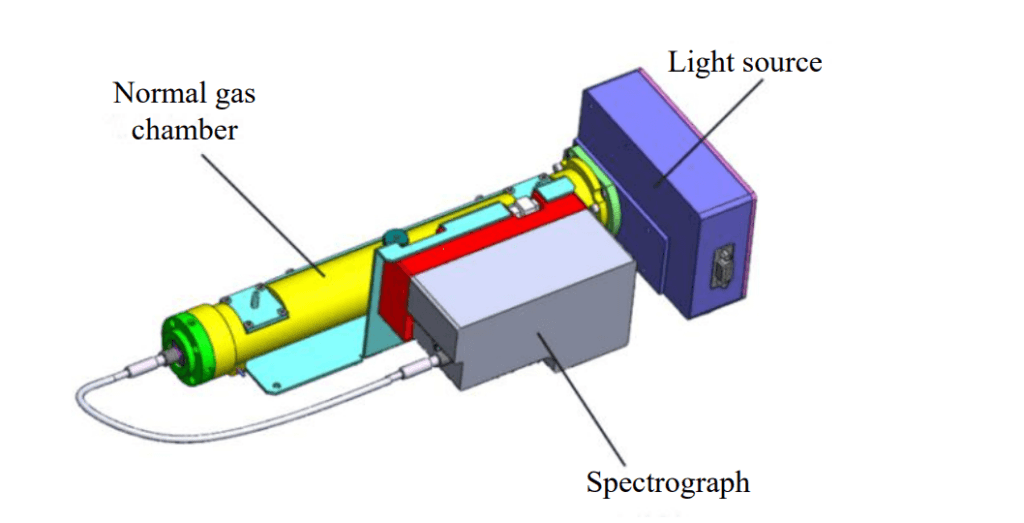

UV-GAS-100M UV-DOAS Gas Sensor is an independently self-developed flue gas analysis product that is suitable for online gas analysis of environmental protection and industrial control sites. Based on Ultraviolet Absorption Spectroscopy and Differential Optical Absorption Spectroscopy, it adopts an optical technology platform and can conduct online analysis and measurement for gases including SO2, NO, NO2, H2S, Cl2 NH3, etc. Under normal conditions, it is used to measure gas components of SO2, NOX, and other gas components that can be extended. One module can simultaneously carry out measurements for 5 gas components at maximum. The product has features of high measurement accuracy and reliability, fast response, and wide application.

How Can You Ensure the Accuracy of a UV-DOAS Gas Analyzer?

Like any precision instrument, maintaining the accuracy of a UV-DOAS gas analyzer requires regular calibration and maintenance. However, UV-DOAS technology is known for its stability and requires less frequent calibration than other gas detection methods.

- Calibration: Calibration involves comparing the analyzer’s readings with known gas concentrations to ensure that it is providing accurate data. Regular calibration helps prevent drift in measurements, which can occur over time due to factors like component wear or environmental changes. Most UV-DOAS analyzers come with automated calibration features, making it easier to maintain accuracy without requiring constant manual adjustments.

- Routine Maintenance: Although UV-DOAS analyzers are robust and durable, routine maintenance is still necessary to ensure long-term accuracy and reliability. This typically involves checking the light source, cleaning optical components, and verifying that the system is free from contamination. By keeping the equipment in good condition, users can maximize its lifespan and maintain consistent performance.

- Environmental Factors: While UV-DOAS analyzers are designed to handle harsh environments, extreme conditions can still affect performance if not properly managed. For example, excessive dust or humidity may interfere with light transmission, leading to inaccurate measurements. Ensuring that the analyzer is properly housed and that environmental factors are controlled can help maintain optimal performance.

Q&A

Q1: What is a UV-DOAS gas analyzer?

A UV-DOAS (Ultraviolet Differential Optical Absorption Spectroscopy) gas analyzer is a highly accurate instrument used to measure the concentration of gases in a given sample. It works by passing ultraviolet light through a gas sample and detecting how much light is absorbed at specific wavelengths. This information is then used to determine the concentrations of gases such as sulfur dioxide (SO₂), nitrogen oxides (NOx), and ozone (O₃).

Q2: How does a UV-DOAS gas analyzer work?

The UV-DOAS gas analyzer works by sending ultraviolet light through a gas sample. As the light passes through the sample, certain gases absorb the light at specific wavelengths. A spectrometer then measures the light that passes through and compares it to the initial intensity. This difference in light absorption helps identify and quantify the gases present in the sample.

Q3: What gases can a UV-DOAS gas analyzer detect?

UV-DOAS analyzers are particularly effective at detecting sulfur dioxide (SO₂), nitrogen oxides (NOx), ozone (O₃), and other trace gases. These gases are commonly monitored in environmental applications, industrial processes, and emission controls. The broad detection spectrum and high sensitivity make it an ideal tool for detecting gases in low concentrations.

Q4: What are the main applications of UV-DOAS gas analyzers?

UV-DOAS gas analyzers are used in various fields, including:

- Environmental Monitoring: For tracking air pollution levels.

- Industrial Process Monitoring: Ensuring optimal and safe production conditions.

- Emission Control: Meeting regulatory standards by monitoring industrial emissions.

- Scientific Research: Studying atmospheric conditions and compositions.

You can read more about its applications here.

Q5: How does UV-DOAS compare to traditional gas analyzers?

Compared to traditional gas analyzers (e.g., infrared or chemical sensors), UV-DOAS analyzers offer higher sensitivity, multi-component detection, and real-time monitoring. Additionally, UV-DOAS analyzers have minimal cross-sensites and can detect gases in very low concentrations, making them suitable for complex environments.

More comparisons can be found here.

Q6: What are the maintenance requirements for a UV-DOAS gas analyzer?

Although UV-DOAS analyzers are robust and stable, they still require routine calibration and maintenance to ensure accuracy. Regular cleaning of optical components, checking for contamination, and automated calibration are important steps to keep the device in optimal condition.

Conclusion

The UV-DOAS gas analyzer is a cutting-edge tool for detecting and monitoring gas concentrations across a wide range of applications. Its ability to provide real-time, accurate, and multi-component gas detection makes it an indispensable technology in industries such as environmental monitoring, industrial process control, and emissions compliance. With minimal maintenance and high reliability, UV-DOAS offers a long-term solution for accurate gas analysis, even in challenging environments.