An online FTIR (Fourier Transform Infrared) gas analyzer ESE-FT600 is a self-developed product targeted at online gas analysis of environmental protection and industrial control. Based on Fourier Transform Infrared Spectroscopy (FTIR), it can simultaneously monitor multiple gas components in exhaust gas, including SO2, NOx (NO, NO2), CH4, HCl, HF, CO, CO2, O2, H2O, etc. Other gas components also can be extended as required, such as NH3, SO3, N2O, VOCs, etc. Multi-component measurement of AlO realizes accurate qualitative/quantitative analysis of waste incineration/ultra-low flue gas emission and high integration, greatly reducing maintenance cost and system cost.

Online FTIR gas analyzers are integral in industries such as petrochemical, power generation, waste management, and manufacturing, as well as in environmental monitoring and research. Their ability to provide detailed and reliable data makes them indispensable tools for ensuring process efficiency, worker safety, and environmental protection.

| Brand A | Brand B | Our Product |

|---|---|---|

| High-temperature FTlR | High-temperature NDlR | High-temperature FTIR |

| A device can measure multiple-components simultaneously | A device can measure multiple-components simultaneously | A device can measure multiple componentssimultaneously |

| Low detection limit | Poor detection limit | Low detection limit, fast response |

| High cost | Low cost | Low cost, high cost performance |

| Less maintenance | Complicated structure, more maintenance | Modular design, less maintenance |

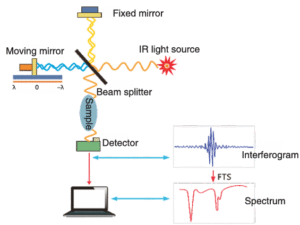

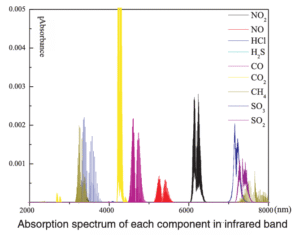

The FTIR technology owns wide coverage area. Each gas absorption has small interference, and it can simultaneously measure multiple gas components. When the infrared radiation enters the interferometer, it will produce two beams of coherent light. The gas sample in the gas chamber absorbs energy of coherent light with specific wavelength. When interferogram that contains sample gas absorption information has been detected by the detector, computer will perform Fourier transform and obtain the infrared spectrogram finally.

When the infrared radiation passes gas sample, it can be observed that some infrared radiation of certain wavelength cannot get through the gas completely. That is to say, different gases will absorb the infrared radiation of specific wavelength. The infrared radiation interacts with gas molecules, and then the gas molecules gain energy from the infrared radiation to start vibration or rotation. All the vibration and rotation will cause absorption of specific wavelength in the infrared radiation. The energy transduction from infrared radiation to gas molecules leads to intensity reduction of some wavelengths in the infrared radiation.

The absorption spectrum presents absorption degree of sample in different infrared bands through graphical form. Spectrum displays a function that infrared radiation is regarded as wavelength when passing through gas. For each wavelength, to get transmittance T, divide the infrared radiation intensity when passing through the sample gas by the infrared radiation intensity when entering the sample gas. When there is no absorption, the value of transmittance T is 1 (or 100%), which indicates the infrared radiation in that wavelength is 100% passing through the sample gas, If the radiation intensity that enters the sample is I0, and the radiation intensity through the sample is l, then the transmittance T can be expressed as:

T=I/I0

In formula: T=Transmittance I0=Intensity when entering the sample I=Intensity when passing through the sample

In addition, the logarithm of reciprocal value of transmittance T is the absorption of infrared radiation:

A= log10(1/T)

In formula: T=Transmittance A=Absorbance

Every kind of gas will be absorbed at specific position, and concentration information for each kind of gas can be forecasted through the established relation model between sample gas absorbance and concentration.

| Parameter | Index | Parameter | Index |

|---|---|---|---|

| SO2 range | 200mg/m³ | HCl range | 200mg/ m³ |

| NO range | 300mg/ m³ | HF range | 200mg/ m³ |

| NO2 range | 300mg/ m³ | CO2 range | 20% |

| NOx range | 759mg/ m³ | O2 range | 25% |

| CO range | 300mg/ m³ | Zero drift | ≤±2%F.S/7d |

| H2O range | 40% | Span drift | ≤±2%F.S/7d |

| CH4 range | 300mg/ m³ | Linearity error | ≤±2%F.S |

| Measuring principle | SO2, NOx (NO, NO2), CH4, HCl, HF, CO, CO2, O2, H2O: FTIR Technology |

|---|---|

| O2: Zirconia principle | |

| Communication interface | RS232, RS485, etc. |

| Communication protocol | Support modbus protocol, customizable |

| Power supply | Rated voltage: (220 +22) VAC; rated power: 1200W; AC frequency: 50/60 Hz |

| Working condition | Ambient temperature: -10℃~35℃; Ambient humidity: <90%RH, non-condensing |

| Dimension | 19 inch*5U*610mm |

| Weight | 35kg |

Here’s how the online FTIR gas analyzer works:

An online FTIR (Fourier Transform Infrared) gas analyzer is a sophisticated instrument used for continuous monitoring and analysis of gas compositions. This type of analyzer is particularly useful in industrial and environmental applications where real-time monitoring of various gases is critical.

| Brand A | Brand B | Our Product |

|---|---|---|

| High-temperature FTlR | High-temperature NDlR | High-temperature FTIR |

| A device can measure multiple-components simultaneously | A device can measure multiple-components simultaneously | A device can measure multiple componentssimultaneously |

| Low detection limit | Poor detection limit | Low detection limit, fast response |

| High cost | Low cost | Low cost, high cost performance |

| Less maintenance | Complicated structure, more maintenance | Modular design, less maintenance |

Measuring carbon dioxide (CO2) is important for understanding the role it plays in the environment and its effect on climate change. CO2 is a major component of Earth’s atmosphere, and it traps heat like a blanket, causing global temperatures to rise. Too m uch CO2 can lead to drastic changes in our weather patterns and ecosystems, so monitoring its levels is essential for predicting future climate conditions. Additionally, measuring CO2 can help us better understand our impact on the environment and make informed decisions about how to reduce emissions and slow down down down down down global warming. By analyzing CO2 data over time, we can develop strategies to mitigate the effects of climate change and ensure a sustainable future.

Before industrialization, the global average annual atmospheric carbon dioxide concentration was 278ppm (1ppm is one part per million). In 2012, the global annual average atmospheric carbon dioxide concentration was 393.1ppm. By April 2014 , the monthly average carbon dioxide concentration in the northern hemisphere atmosphere exceeded 400ppm for the first time. . 2. Global climate warming, the continuous aggravation of the atmospheric greenhouse effect leads to global climate warming, resulting in a series of global climate problems that cannot be predicted by today’s science. According to the International Climate Change Economics Report, if human beings maintain the current way of life, by 2100, there will be a 50% chance that the global average temperature will rise by 4°C.

Copyright © 2023 esegas.com, All rights reserved.

Enviro Solutions Technology Co., Ltd (ESE Technology) is a gas analyzer manufacturer and leading provider in ODM/OEM services for gas analysis systems used by international famous brands.

We will contact you within 1 working day, please pay attention to the email with the suffix “[email protected]” .

We’ll send you the catalog as soon as you submit your email