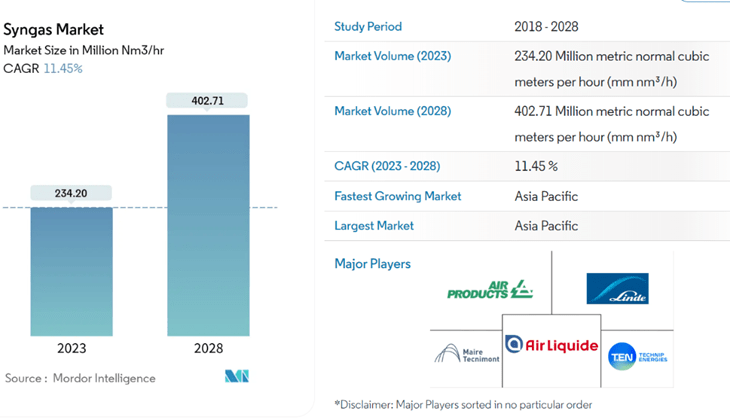

In the modern industrial production process, especially in the fields of chemical industry, petroleum and energy, the generation and application of synthesis gas (“syngas” for short) occupies an indispensable position. Synthesis gas is a mixed gas composed of carbon monoxide, hydrogen and other gas components. It is widely used in many fields such as chemical raw materials, energy production and environmental protection. The instrument that accurately analyzes this gas, the syngas analyzer, is the invisible hero in industrial production to ensure production efficiency, product quality and environmental safety. This blog will give you an in-depth understanding of the purpose of a syngas analyzer and its important role in modern industry.

Basic Concepts of Syngas

Before we delve into the uses of syngas analyzers, we first need to understand the characteristics of syngas itself.Synthesis gas is mainly composed of carbon monoxide and hydrogen, and often contains small amounts of carbon dioxide, nitrogen, methane and other other components. This gas comes from a variety of sources, such as coal gasification, biomass conversion, and natural gas reforming.

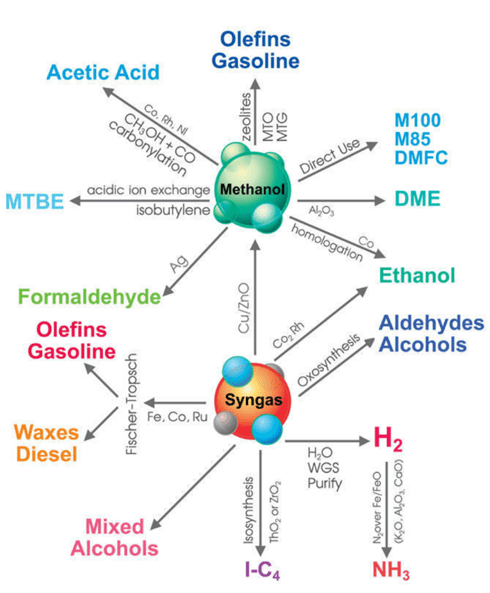

Syngas is equally versatile and can be converted into fuels, ammonia, methanol and a variety of organic chemicals. In these conversion processes, the component ratio of syngas will directly affect the quality and production efficiency of the final product, so strict analysis and control are particularly important.

Syngas Analyzer Core Functions

The core function of the syngas analyzer is to accurately measure the content of each component in the syngas. Based on different detection principles, there are many types of syngas analyzers on the market, such as infrared gas analyzers, thermal conductivity gas analyzers, mass spectrometer analyzers, etc. These instruments can perform specialized analysis on different gas components to ensure the accuracy and reliability of detection results.

Syngas analyzers are capable of detecting small changes in gas composition and are crucial to the control of industrial production processes. For example, in the production process of synthetic ammonia, the ratio of hydrogen and carbon monoxide is extremely strict, and the analyzer can monitor these ratios in real time to ensure the smooth progress of the reaction.

2. Real-time monitoring and control

Most syngas analyzers have real-time monitoring functions. They can be connected to the production system to achieve online monitoring and automatic regulation, effectively avoiding human errors and improving production efficiency and product quality.

3. Environmental protection

In terms of environmental protection, syngas analyzers monitor gas composition and help control pollutant emissions. In particular, monitoring the emissions of harmful gases such as carbon monoxide is crucial to meeting environmental regulations and standards.

How Syngas Analyzer Works

Syngas analyzer is a complex analytical device used to measure the concentration of various components in syngas. Its working principle usually involves a variety of physical and chemical methods, the most common of which include infrared spectroscopy (IR), thermal conductivity (TC), gas chromatography (GC) and mass spectrometry (MS). Below I will describe these techniques in detail.

Infrared spectroscopy is based on the principle of molecular vibration absorbing infrared light. Different molecules have specific absorption peaks at different wavelengths in the infrared region. In the analysis of syngas, especially molecules such as carbon dioxide (CO2), carbon monoxide (CO) and methane (CH4), all have strong absorption peaks in the infrared spectrum.

work process:

- Measurement: An infrared light source in the analyzer emits a sequence of infrared light that passes through a sample cell containing an unknown concentration of gas.

- Absorption: Different gas molecules absorb infrared light at specific wavelengths based on their unique chemical structures.

- Detection: The infrared light passing through the sample is received by the detector, and the concentration of each component is calculated based on the decrease in light intensity.

- Thermal conductivity method (TC)

The thermal conductivity method is based on the principle of difference in thermal conductivity of gas molecules. Different gas molecules have different thermal conductivities, so by measuring the change in overall thermal conductivity of a gas mixture, the concentration of the individual components can be inferred.

work process:

- Heating: A reference chamber filled with a known gas (usually a gas not included in the syngas, such as helium) and a measuring chamber filled with the syngas sample are heated simultaneously.

- Thermal equilibrium: After the two chambers reach thermal equilibrium, the difference in thermal conductivity will cause a temperature difference and thus a voltage difference.

- Calculation: The voltage difference is measured by precision electronic equipment and converted into concentration information of gas components.

- Gas Chromatography (GC)

Gas chromatography uses the different speeds at which gas molecules pass through a stationary phase (chromatography column) to achieve separation. Each molecule can be separated by migrating through the column at a different rate based on its chemical properties and interactions on the column.

work process:

- Injection: The syngas sample is injected into the column.

- Separation: When a sample passes through a chromatographic column with a carrier gas (usually helium or nitrogen), different components are separated based on their different adsorption forces on the column material.

- Detection: As time goes by, different gas components will flow out from the other end of the chromatographic column and be detected by detectors (such as flame ionization detectors, thermal conductivity detectors, etc.).

Mass spectrometry (MS)

Mass spectrometry is a high-precision analytical technique that identifies and quantifies gas molecules by measuring their mass-to-charge ratio. In syngas analysis, mass spectrometry can provide very detailed compositional information.

work process:

- Ionization: A syngas sample is introduced into a mass spectrometer and the gas molecules are ionized in a vacuum (usually by electron impact).

- Acceleration and separation: The ionized ions are accelerated by the electric field and enter the mass analyzer, where they are separated according to their mass-to-charge ratio.

- Detection: Ions with different mass-to-charge ratios are detected sequentially to obtain mass information of the components.

Syngas analyzers often integrate several of the above technologies to provide comprehensive information about the various components in the syngas. Each of these techniques has its own advantages. For example, infrared spectroscopy is suitable for rapid detection of specific gases, thermal conductivity method is suitable for detecting specific components such as hydrogen, gas chromatography is suitable for the analysis of complex gas mixtures, and mass spectrometry provides the highest resolution and accuracy. Spend. Through these technologies, syngas analyzers play a vital role in industrial process control, safety monitoring and environmental compliance.

Application Examples of Syngas Analyzers In Various Fields

Synthesis Gas (Synthesis Gas or Syngas) due to itsWidely used in modern industry, precise analysis of its composition becomes particularly important. Syngas analyzers play a key role in a variety of areas, including but not limited to:

- Chemical industry

In the chemical industry, synthesis gas is the basis for many chemical reactions and processes. For example, synthesis gas can be converted into liquid fuel through Fischer-Tropsch synthesis reaction; in the synthesis of methanol, ammonia, etc., the proportion and purity of synthesis gas directly affect the yield and quality of the product. The synthesis gas analyzer ensures that the composition of the raw gas meets the requirements during these processes, thereby controlling the synthesis quality of the product and ensuring safe production.

- steel manufacturing

In steel production, especially in the direct reduction of iron process, synthesis gas is used as a reducing agent to reduce iron oxide to produce sponge iron. The composition and purity of the synthesis gas are crucial to the reduction effect, and the analyzer is used in this process to ensure efficient and energy-saving reactions.

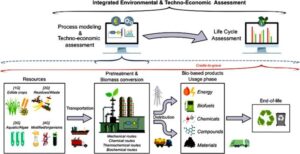

Syngas can be produced from biomass through gasification or anaerobic digestion. The role of the syngas analyzer here isMonitoring and optimizing syngas yield and quality in biomass conversion processes, ensuring the effective utilization and sustainable development of bioenergy.

- Environmental monitoring

Syngas may contain harmful components such as carbon monoxide and hydrogen sulfide, which may have an impact on the environment and human health. The role of the syngas analyzer in environmental monitoring is to detect and control the emissions of these harmful gases in real time to ensure that production activities do not place an excessive burden on the environment.

- Security monitoring

In petrochemical plants, coal mines and other places, syngas analyzers are also used for safety monitoring. For example, toxic gases such as carbon monoxide may be produced in coal mines, and analyzers can be used to provide early warning to prevent accidents.

- research and development

Syngas analyzers are also widely used in scientific research and the development of new technologies. They help researchers understand and improve the process of generating, cleaning and utilizing syngas, promoting the birth of new technologies and the improvement of old processes.

- energy industry

In the energy industry, especially in gasification power plants, syngas is used as fuel, and its combustion efficiency and emission standards need to be strictly controlled. The analyzer can monitor and adjust the composition of the syngas in real time to optimize the combustion process, reduce the emission of harmful substances, and improve power generation efficiency.

- Food and Beverage Industry

Although not its primary use, syngas may be produced or required in certain fermentation processes in the food and beverage industry. In these processes, assurance of syngas purity and composition is necessary to produce specific products.

Our syngas analyzers

Conclusion

As the invisible hero of industrial progress, the syngas analyzer’s value is not only reflected in improving industrial efficiency and product quality, but also in its contribution to environmental protection. In the future, with the continuous advancement of technology, these analyzers will become more intelligent and precise, becoming an important force in promoting sustainable industrial development. For various industries that use syngas, understanding and applying advanced syngas analysis technology has become part of the company’s competitiveness. If you have any questions or issues,Welcome to get in touch with us!