With the rapid development of industrialization, more and more gases are used in various industries. However, different types of gases have different impacts on human health and production safety. Therefore, gas detectors have become indispensable in various fields. One of the safety monitoring equipment. This article will discuss the current market status of the gas detector industry and its future development trends.

Overview of Gas Analyzer Market Situation

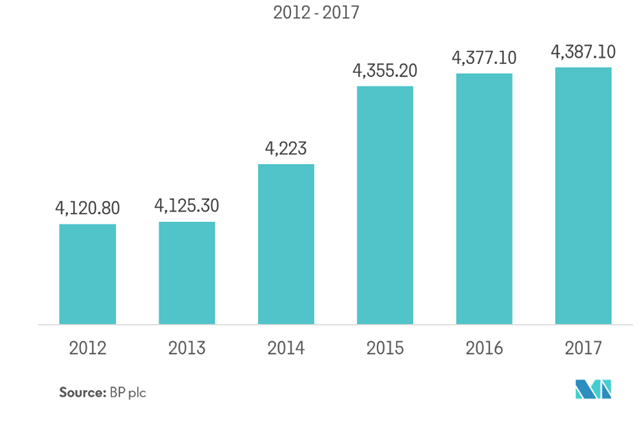

According to market research reports, the global gas detector market size was approximately US$2 billion in 2019 and is expected to reach US$3.6 billion by 2025, with a compound annual growth rate of approximately 8.6%. At present, the gas detector market is mainly divided into two categories: portable gas detectors and fixed gas detectors.

The increasing popularity of NDIR gas analyzers is also attributed to their ability to analyze multiple gases in harsh environments, lack of cross sensitivity, longer service life, and lower cost of ownership.

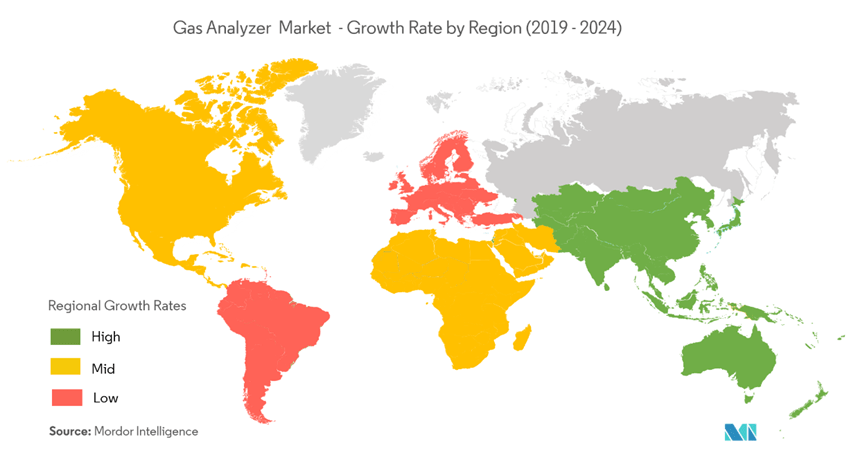

On the other hand, ZR gas analyzers are mainly used to analyze oxygen concentrations in clean rooms, biochemical laboratories, and the food packaging industry, where continuous measurement of flowing gases is required. In addition, investment in new factories in the power, chemical, and petrochemical industries, as well as the oil and gas industries in the Asia Pacific region, continues to increase, making the region one of the fastest-growing regional markets.

In addition, technological advancements in wireless communication facilities and sensor technology are also expected to drive market growth. Due to its sturdy and durable characteristics and ability to work in corrosive chemical environments, NDIR analyzers are the preferred choice for the petroleum and natural gas as well as chemical and petrochemical industries. They can also accept a certain degree of cross sensitivity between different gases.

1. Portable gas detector

Due to its small size and ease of use, portable gas detectors are suitable for real-time detection needs in various fields, such as mining, construction, oil and gas, environmental protection, etc. According to statistics, the global portable gas detector market size was approximately US$920 million in 2019, and is expected to reach more than US$1.5 billion by 2025, with a compound annual growth rate of approximately 7.5%. At present, the market competition for portable gas detectors is relatively fierce. The main manufacturers include RAE Systems of the United States, Dräger of Germany, Crowcon of the United Kingdom, and Honeywell of the United States.

2. Fixed gas detector

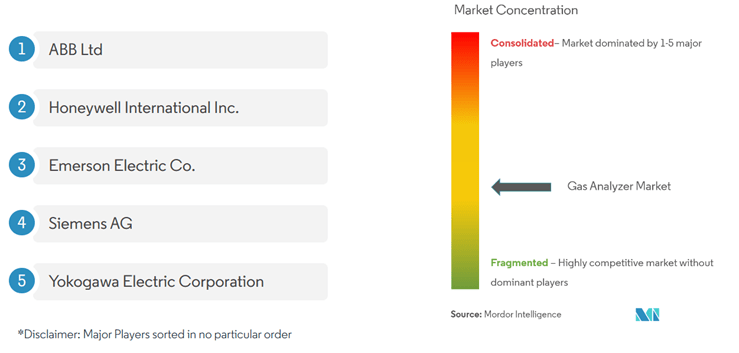

Fixed gas detectors are installed in fixed places for long-term monitoring of the concentration of harmful gases in the environment. At present, the main demand for fixed gas detectors in the market comes from chemical industry, oil and gas, electric power, mining and other fields. According to a report released by market research organization Fact.MR, the global fixed gas detector market size was approximately US$1.15 billion in 2018 and is expected to grow to more than US$1.7 billion by 2028, with a compound annual growth rate of approximately 4.5%. Currently, major manufacturers in the fixed gas detector market include Honeywell from the United States, ABB from Switzerland, Schneider Electric from France, Dräger from Germany, Crowcon from the United Kingdom, etc.

Laser Series Gas Analyzers and Their Market Prospects

The laser gas analyzer uses a semiconductor laser as the light source and uses TDLAS (Tunable Diode Laser Absorption Spectroscopy, tunable semiconductor laser absorption spectroscopy) technology to modulate the signal.

Semiconductor lasers are small in size, light in weight, long in life, high in efficiency, and do not require high-voltage power supply. These characteristics make semiconductor lasers the most widely used lasers in industry.

There are many types of process analytical instruments, classified according to the type of analyte and the technique used to analyze the element. Laser-based gas analyzers are a type of analytical instrument that utilize a laser source to determine the type and amount of elements in the gas phase. Instruments such as Tunable Diode Laser Absorption Spectroscopy (TDLAS), Raman Analyzers, and Cavity Ring Attenuation Spectrometers are some of the key laser-based gas analyzers widely used in the industry.

Currently, laser gas analyzers on the market mainly use Tunable Diode Laser Absorption Spectrometer (TDLAS) technology. TDLAS technology is essentially a spectral absorption technology that obtains the concentration of gas by analyzing the selective absorption of laser by gas. It differs from traditional infrared spectrum absorption technology in that the semiconductor laser spectrum width is much smaller than the broadening of the gas absorption spectrum line.

1. In-situ type

The laser gas analyzer uses in-situ (or in-line) measurement technology to measure directly on the process pipeline under test. Different from traditional extraction gas analysis, in-situ analysis does not require sampling pipelines to extract and transport sample gas, nor does it require sample preprocessing. In this way, the basic configuration of the laser analyzer is much simpler than that of the extraction analyzer.

2. Extractive type

When applying traditional extraction gas analyzers, it is necessary to understand the composition of the medium to be measured and consider the possible mutual interference between the components, so as to judge and select the appropriate type of analyzer. The wavelength of the laser emitted by the laser gas analyzer is precisely modulated to equal the absorption line of a specific gas. The monochromatic laser emitted is only selectively absorbed by specific components with specific absorption lines within the scanning spectral range. There is no any trace during the measurement process. cross interference. Relatively higher accuracy than traditional analysis methods.

According to statistics and forecasts from QYR (Hengzhou Bozhi), the global laser gas analyzer market sales will reach US$472.49 million in 2021, and are expected to reach US$672.36 million in 2028, with a compound annual growth rate (CAGR) of 4.66% (2022-2028). From a regional perspective, the Chinese market has changed rapidly in the past few years. The market size in 2021 will be US$134.80 million, accounting for approximately 28.53% of the global market. It is expected to reach US$200.21 million in 2028, when the global share will reach 29.78% .

At the consumption level, China is currently the world’s largest consumer market, accounting for 28.53% of the market share in 2021, followed by Europe and North America, accounting for 22.71% and 21.75% respectively.

In terms of product types, in-situ occupies an important position, and its revenue share is expected to reach 74.84% in 2028. At the same time, in terms of application, the share of oil and natural gas in 2021 will be approximately 24.16%, and the CAGR in the next few years will be approximately 4.46%. Key process industries such as petrochemicals, steel, and aerospace are very promising for the growth prospects of the laser gas analyzer market due to low maintenance costs.

In terms of manufacturers, globally, the core manufacturers of laser gas analyzers mainly include Endress+Hauser, Servomex (Spectris), Mettler Toledo, Focus Technology, ABB, Siemens, Yokogawa Electric, NEO Monitors, Baker Hughes, SICK, and HORIBA , AMETEK, Fuji Electric,, Emerson, Blue Shield Optoelectronics etc. In 2021, the world’s first-tier manufacturers mainly include Endress+Hauser, Servomex (Spectris) and Mettler Toledo. The first-tier manufacturers account for approximately 30.04% of the market share; the second-tier manufacturers include Concentrator Technology, ABB, Siemens, Yokogawa Electric, and NEO. Monitors, Baker Hughes, SICK, HORIBA, etc., occupy a total share of 35.87%. It is expected that industry competition will become more intense in the next few years, especially in the Chinese market.

Infrared Series Gas Analyzers and Their Market Prospects

Industry Overview

Infrared gas analyzer is an analytical instrument developed by utilizing the absorption properties of infrared radiation by substances. It is widely used in environmental monitoring, industrial production, safety testing and other fields. Infrared gas analyzer can measure the concentration of various gases and detect multiple gases at the same time.

At present, my country’s infrared gas analyzer industry has entered a stage of rapid development, and market demand continues to increase. The industry mainly focuses on measuring instruments, environmental protection instruments, industrial control instruments and other fields. According to statistical data, the market size of my country’s infrared gas analyzer industry reached 13.717 billion yuan in 2019, a year-on-year increase of 8.3%. The market size is expected to continue to grow in the next few years.

Market prospect analysis

1. Development drivers

With the strengthening of environmental management, the realization of industrial environmental protection and the requirements of safety supervision, the demand for infrared gas analyzers is gradually increasing. Infrared gas analyzers are widely used in petrochemical, metallurgy, environmental protection, chemical industry, pharmaceutical, food and other fields. Especially in the fields of environmental protection and industrial safety management, infrared gas analyzers play an irreplaceable role.

2. Market growth forecast

According to market research statistics, from 2019 to 2025, the global infrared gas analyzer market will have a compound annual growth rate of 6.2%. The global market size is expected to reach US$1.28 billion by 2025. Looking at the domestic market, my country’s infrared gas analyzer market size has reached 13.717 billion yuan in 2019, a year-on-year increase of 8.3%. The market size will continue to grow in the next few years. According to predictions, my country’s market size will reach about 25 billion yuan in 2025.

3. Market Competition Pattern

The main manufacturers in my country’s infrared gas analyzer industry market include Yokogawa Instruments, Tsinghua Tongfang, Tianjin Tianming Electronics, The Linde Group, Pepperl+Fuchs, etc. At present, the industry competition pattern is characterized by high market concentration, with leading companies occupying an absolute advantage. Competition between companies is mainly carried out in aspects such as product quality, technological innovation and after-sales service.

4. Development direction

The market prospect of infrared gas analyzers is broad, and the future development direction is mainly in the following aspects:

1. Improve the accuracy and measurement range of the product.

With the advancement of science and technology, the accuracy and measurement range of infrared gas analyzers have been greatly improved. However, in order to adapt to market demand, relevant technologies need to be continuously improved and strengthened in the future.

2. Enhance intelligence.

Infrared gas analyzers need to continuously monitor the composition of gases. In the future, they should also be more intelligent, especially to achieve remote monitoring.

3. Expand application areas.

Gas detection and analysis are the core functions of infrared gas analyzers. In the future, the application and promotion in agriculture, medical and health, environmental protection and other fields should be strengthened to expand the application areas.

4. Build brand influence.

As competition becomes increasingly fierce, the infrared gas analyzer industry needs to increase brand promotion and establish brand management to increase brand influence.

5. Conclusion

Infrared gas analyzer is an integrated and multi-functional detection instrument worth looking forward to in the future, and it has broad market prospects in the future. All companies should continue to strengthen technological innovation and improve product quality and service quality, which will be a key factor in market success.

Future Development Trends

1. Improvement of production process

With the rapid development of technology, the manufacturing process of gas detectors has been significantly improved. The manufacturing process based on nanotechnology can not only greatly improve the sensitivity of gas detectors, but also effectively reduce the cost of gas detectors, and is expected to achieve large-scale production.

2. Application of intelligent technology

The application of intelligent technology in the field of gas detection has gradually become popular. For example, a gas detector with cloud computing function can transmit the detection results to the cloud in real time, thereby realizing data sharing. At the same time, the monitoring equipment can also perform intelligent early warning and adjustment at any time based on changes in the detection data report.

3. Development of independent intellectual property technology

In recent years, China’s gas detector market has gradually attracted the attention of domestic and foreign manufacturers. The development of technological research and applications in the fields of optoelectronics, semiconductors, electronics and other fields has laid the technical foundation for gas detectors. In the future, the emergence of China’s independent intellectual property technologies will surely promote the development of the gas detector market.

4. Continuous increase in market demand

With the continuous improvement of environmental awareness, the market demand for gas detectors will continue to increase, especially in mining, construction, chemical industry, electric power and other fields. At present, the gas detector industry is highly competitive and has huge market potential in the future. Manufacturers need to continuously innovate and develop new products according to market demand and provide more professional solutions to meet customer needs.

Conclusion

In short, the gas detector market has broad development prospects. In the future, with continuous technological breakthroughs and market expansion, gas detectors will be widely used. Manufacturers need to continuously improve product performance, reduce product costs, and transform marketing models to meet customer needs with more professional products and services and gain more market share.