(Biomass Gasification Power Plant)

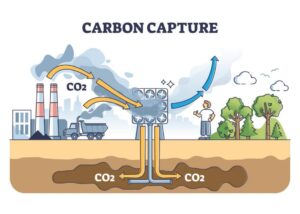

Real-time CO₂ monitoring is a critical lever for optimizing biofuel fermentation and biomass gasification. Continuous off-gas analysis reveals microbial growth rate and reactor balance, enabling better process control. The carbon dioxide (CO₂) outcome is clear: operators gain tighter control, higher biofuel yields, less waste and downtime, safer operation, and confident compliance with environmental and quality standards.

Why Is CO₂ a Critical Indicator in Biofuel Fermentation and Biomass Gasification?

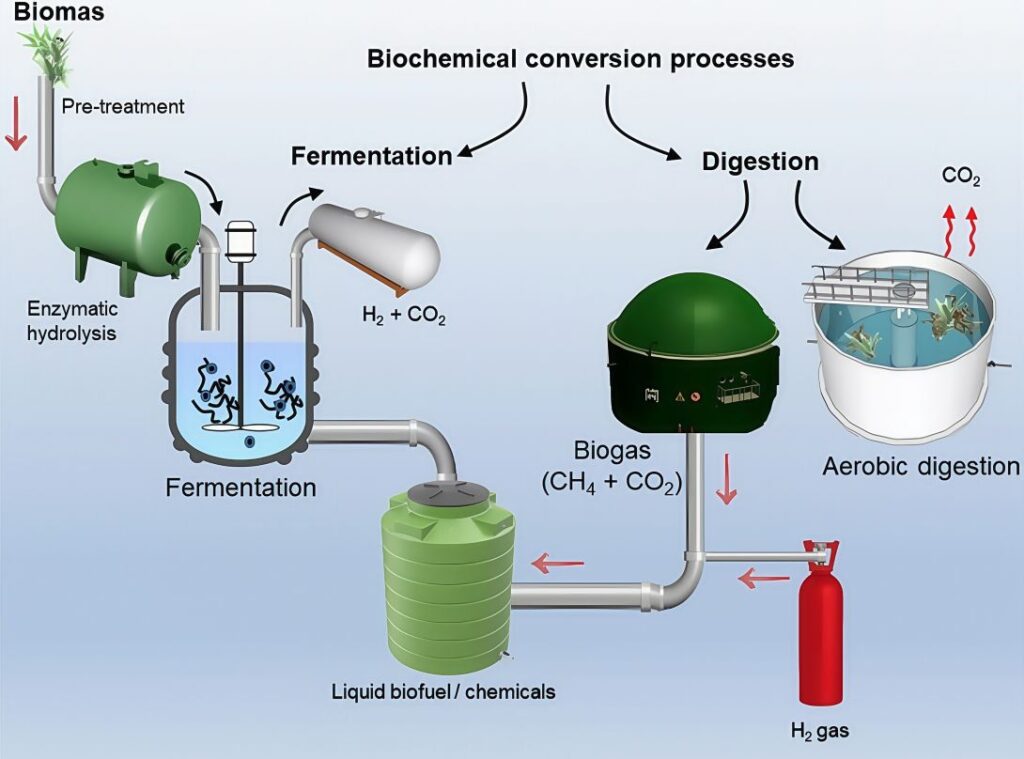

Microbial fermentation converts biomass into biofuels or biochemicals, while biomass gasification thermo–chemically cracks solid feed into syngas (CO, H₂, CO₂, CH₄). In both cases, CO₂ is much more than a waste by-product—it signals reactor health:

- In fermentation, CO₂ evolution correlates with cell growth and substrate conversion.

- In gasification, CO₂ (via water-gas shift and oxidation reactions) fixes the H₂:CO ratio and calorific value of syngas.

By treating CO₂ as a strategic input, plants can infer metabolism and conversion efficiency in real time. The carbon dioxide evolution rate (CER) and respiratory quotient (RQ = CO₂/O₂) reveal microbial activity and balance of aerobic/anaerobic pathways. Thus, continuous CO₂ monitoring serves as a window into both bioreactor metabolism and gasifier equilibrium.

How Does CO₂ Behavior Reflect Process Efficiency in Fermentation and Gasification?

(CO₂ Measurement For Fermentation)

- Fermentation (biofuels/bioproducts): In aerobic or anaerobic fermenters, emitted CO₂ directly reflects the microbial growth rate, substrate uptake, and stress responses. As one review notes, “exhaust gas monitoring is a powerful tool for process control” because “fermentation activity is reflected in the consumption of O₂ and the production of CO₂”. Tracking carbon dioxide evolution rate (CER) alongside oxygen uptake rate (OUR) quantifies biomass production. The ratio of respiratory quotient (RQ = CO₂/O₂) shifts when cells switch metabolism (e.g. to ethanol production under oxygen limitation)metersolution.commetersolution.com.

In practice, rising CO₂ can signal rapid growth or metabolic overflow, while drops (for given feed rates) may warn of inhibition or substrate exhaustion. Monitoring CO₂ lets operators adjust feed and oxygen transfer in real time to keep the culture in its optimal window of productivity.

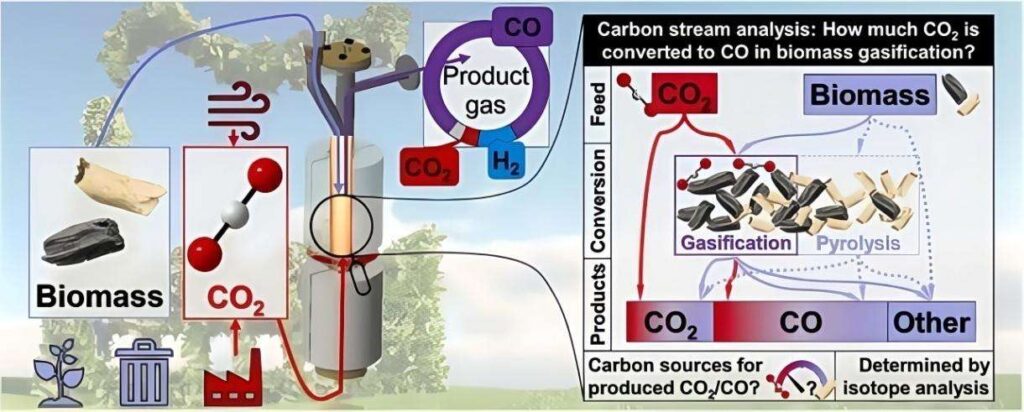

(CO₂ Conversion to CO in Gasification)

- Gasification (syngas production): In a biomass gasifier, CO₂ concentration is a key component of syngas. Typical syngas contains roughly 5–15% CO₂, along with 25–30% H₂ and 30–60% CO. The CO₂ level influences the water–gas shift equilibrium (CO + H₂O ⇄ CO₂ + H₂) and thus the H₂/CO ratio. For example, adding steam or air alters CO₂ content, changing hydrogen yield and syngas calorific value. As industry experts emphasize, “The volume fractions of CO, CO₂, CH₄ and H₂ are important parameters of process control” in a gasifier. Even slight composition changes affect combustion quality and downstream synthesis: in steelmaking (an analog for gasifiers) a “slight deviation in gas composition can significantly impact process efficiency”.

By monitoring CO₂ (with other components), operators ensure the gasifier feed and reactor conditions stay balanced. For instance, an unexplained rise in CO₂ might indicate excessive oxidation or feed variation, prompting adjustments to the air/steam ratio.

In short, CO₂ measurements enable control of the H₂:CO ratio, energy content, and carbon conversion of syngas.

How Can CO₂ Analyzer Improve Bioprocess Control and Performance?

(Bioprocessing monitoring and control)

CO₂ analyzer can be installed at key points:

- For fermentation: An sensor or sampling probe in the exhaust (off-gas) line.

- For gasifiers, a hot-gas sensor after quench or a cooled syngas sampling port.

Many setups simply tap a slip-stream of exhaust gas to a bench analyzer or inline detector. Because CO₂ (and O₂) exchange with the liquid phase is rapid, real-time off-gas sensing effectively tracks the Oxygen Transfer Rate (OTR) and CER in parallel with biochemical conversion. Data from these sensors feed process control systems such as PLCs (Programmable Logic Controllers) and SCADA (Supervisory Control and Data Acquisition) systems to enable proactive adjustments – for example, modulating air or steam flow, feed rate, or agitation to maintain target rates.

Modern CO₂ Analyzers use infrared or laser spectroscopy to measure multiple gases simultaneously. The table below compares typical analyzer technologies for such applications:

| Feature | ESEGAS Process Gas Analyzer | Conventional NDIR Analyzer | Gas Chromatograph (GC) | Mass Spectrometer (MS) |

| Technology | TDLAS + NDIR (multi-channel IR lasers) | Non-dispersive IR (single gas) | Gas chromatography (sampling) | Quadrupole/sector MS (vacuum) |

| Gases Measured | Multi-gas (CO, CO₂, CH₄, H₂, O₂, etc.) | Typically CO₂ (and CO) only | Any volatile analyte (with columns) | Broad range (all gases with ionization) |

| Range & Accuracy | 0–100% span, ppm sensitivity; ±2% (CO, CO₂, CH₄) | 0–100% span; ±2–5% accuracy | ppb–% levels; high precision | ppm–%; very high sensitivity |

| Calibration | Calibration-free (TDLAS) | Requires periodic reference gas | Requires standards and calibration | Requires frequent calibration |

| Response Time | Fast (seconds) real-time output | Seconds to minutes | Minutes per run (batch) | Fast (seconds), but data processing |

| Maintenance & Cost | Low (solid-state optics); moderate cost | Moderate; optical components | High maintenance (columns, gas) | Very high (pump, vacuum, skilled ops) |

| Integration | Built for online integration (4–20mA, Modbus); explosion-proof cases | Generally analog output | Lab-based or sample loops | Usually lab/instrument rack, needs gas connections |

The Table Comparison of CO₂/Process-gas analyzer options. ESEGAS CO₂ analyzer use TDLAS and NDIR to measure multiple gases in situ, yielding fast, high-resolution data without consumables. Conventional NDIR analyzer is simpler but less sensitive and need calibration. Gas chromatographs give precise mixtures but are slow and offline. Mass spectrometers detect trace components yet require complex maintenance.

Using such CO₂ analyzer, real-time CO₂ data supports proactive control: for example, if CO₂ production slows unexpectedly, the control system can increase agitation or oxygen supply to boost microbial uptake. Likewise, in a gasifier, detecting a dip in syngas CO₂ might trigger additional steam to stabilize the H₂/CO ratio. This continuous feedback loop – often managed via SCADA dashboards – turns CO₂ from a blind spot into a steering signal for efficiency.

What Is the Business Value of Using CO₂ Analyzer in Biofuel Production?

Implementing CO₂ analyzer for CO₂ monitoring delivers clear bottom-line benefits:

- Higher Yields and Productivity: By tracking the carbon dioxide evolution rate (CER) and RQ, operators can keep microorganisms in their optimal growth phase. As one industry report notes, “monitoring CO₂ and O₂ helps determine the respiration rate … and thereby increase the efficiency of production”. Inline CO₂ control leads to “higher product yields and improved product quality” in fermentation processes. In gasification, precise gas composition control maximizes fuel-to-syngas conversion and downstream biofuel output.

- Reduced Downtime & Waste: Real-time gas data catches process upsets early. Deviations in CO₂ flag contamination, nutrient depletion or equipment faults before a batch spoils. Inline monitoring “results in cost savings due to reduced product losses, energy consumption, and labor”. Maintaining optimal conditions minimizes wasted feedstock and lowers off-spec product that must be recycled or discarded.

- Regulatory and Quality Compliance: Many bio-industries must meet emissions and GMP standards. Continuous CO₂ monitoring ensures greenhouse gas emissions are tracked for environmental reporting. It also underpins product quality by ensuring the fermentation or gasifier is operating within validated parameters. As ESEGAS notes, analyzers provide the feedback to “meet emission limits, demonstrate compliance, and implement corrective actions when necessary”. In pharmaceutical or food-grade fermentations, this metrology supports batch release and audit trails (e.g. CER as a Critical Quality Attribute).

- Cost Savings & Efficiency: Better control translates to lower energy and feed costs. For example, by matching aeration to biological demand (CO₂-linked), a plant avoids over-blowing air (and cooling costs). Upset events (like starvation or oxygen depletion) are swiftly corrected, avoiding lengthy recovery periods. Overall, plants see “increased efficiency, improved product quality, reduced energy consumption, and minimized emissions” from gas monitoring. Those gains justify the analyzer investment through higher throughput and utility savings.

Therefore, CO₂ monitoring drives a virtuous cycle: better control → higher yield and quality → lower cost and waste → assured compliance, which builds a strong economic case for adoption.

What Makes the ESEGAS CO₂ Analyzer Ideal for Fermentation and Gasification?

The ESEGAS CO₂ Analyzer exemplifies a state-of-the-art solution for these needs. It uses tunable diode laser absorption spectroscopy (TDLAS) and non-dispersive IR to sense multiple gases in real time. Notably, its TDLAS channel for CO₂ is calibration-free – it “does not require calibration with reference gases” – ensuring long-term accuracy with minimal upkeep. In practice, ESEGAS analyzers measure CO₂ (and CO, CH₄) from ppm up to 100% span, with resolution down to 0.001% and accuracy within ±2%. This covers the full range of fermentation off-gas and syngas concentrations.

The ESEGAS unit is designed for industrial robustness and integration. It has a sturdy, explosion-proof enclosure and supports standard outputs (4–20 mA, Modbus, etc.) for PLC/SCADA connection. Its multi-gas capability (optional H₂ and O₂ modules via thermal conductivity or electrochemical sensors) means one analyzer provides a full gas profile. The device also features auto-purging and built-in reference cells for baseline checks, further reducing manual maintenance.

ESEGAS’s CO₂ Analyzer brings laser-grade precision to process gas monitoring. By delivering accurate, continuous CO₂ data (and other components) directly to the control system, it lets plants maintain optimal CER and OTR (oxygen transfer rate) synergy. Operators gain immediate insight into metabolic shifts or feed changes.

As a result, plants using such analyzer report smoother, safer operations and better yields – in line with the broad industry consensus that multi-species analysis “ensures optimized process control and cost savings”.

How Does CO₂ Analyzer Drive Biofuel Process Optimization?

In modern bio-refineries, CO₂ is a strategic input, not just a byproduct. Continuous CO₂ monitoring gives operators a real-time window on fermentation metabolism and gasifier balance. With an inline sensor and smart analytics, CO₂ levels drive automated adjustments that keep the process at peak performance. The key benefits are higher biofuel yields, improved product quality, safer and more consistent operation, and clear compliance with emissions standards.

As reviewed, advanced analyzers like the ESEGAS CO₂ Analyzer make this possible with high accuracy, multi-gas sensing, and seamless control integration. In short, leveraging CO₂ tracking turns complex biochemical and thermochemical processes into tightly controlled, efficient manufacturing.

If you want to know more details, consulting with us please!